Detection method of internal defects of thin-gauge cold rolled steel plates for automobiles

A cold-rolled steel plate and internal defect detection technology is applied in the field of detection of internal defects in thin-gauge automotive cold-rolled steel plates. It can solve problems such as difficult positioning, long detection time, and inability to identify, so as to achieve rapid analysis and positioning, and shorten the search time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] refer to figure 1 , figure 2 , image 3 , Figure 4 , the present invention will be further described in conjunction with embodiment. It should be understood that the following specific embodiments are only used to illustrate the present invention but not to limit the scope of the present invention.

[0027] In this embodiment, the sample plate to be tested is a cold-rolled steel plate for automobiles with a thickness of 1.15 mm.

[0028] a. Cut the cold-rolled steel plate to be tested into a 300×200mm basic model, and use a metal lettering pen to mark a detection area of 50×50mm on the surface of the basic model.

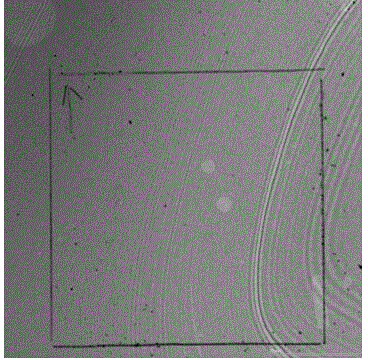

[0029] b. Scan a 50mm×50mm grid area with an ultrasonic scanning microscope with a model PVASAM300ScanningAcousticMicroscope and a transducer frequency of 110MHz to obtain a clear ultrasonic two-dimensional image of the internal defects of the sample, see figure 1 , the scattered black dots in the figure are the distribution positions of the inclusio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com