Plate type heat exchanger with vaporizing space for gas-liquid separating

A plate heat exchanger and space technology, applied in heat exchange equipment, indirect heat exchangers, heat exchanger types, etc., can solve problems such as larger scale, larger system space, and increased system pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

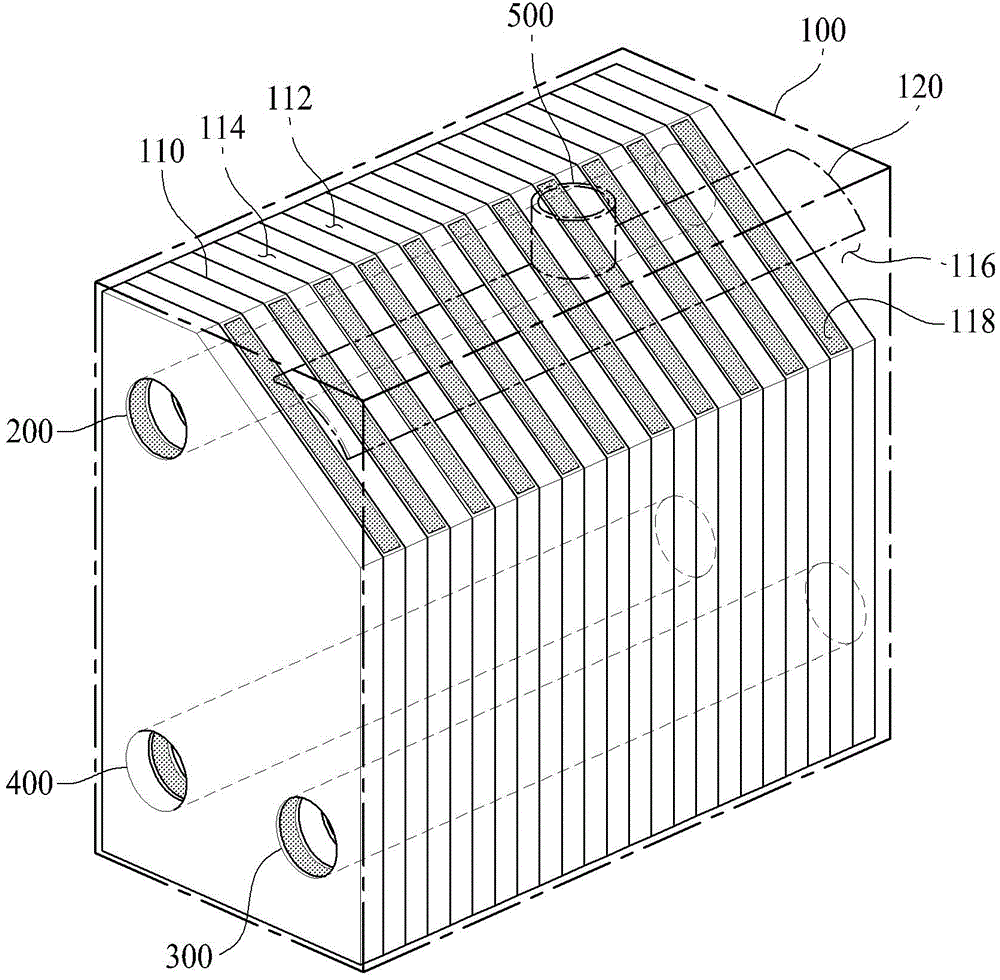

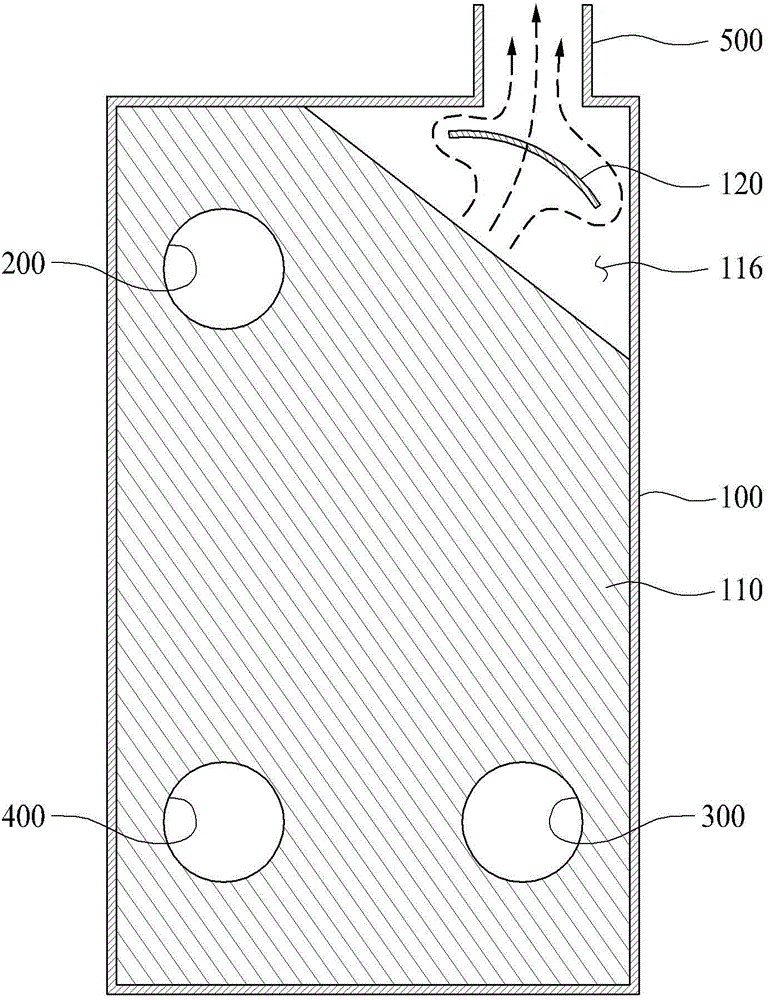

[0029] First, refer to figure 1 and figure 2 , the structure of the first embodiment of the plate heat exchanger according to the present invention will be described in detail.

[0030] in, figure 1 is a drawing showing a first embodiment of a plate heat exchanger according to the present invention, figure 2 is a cross-sectional view of a first embodiment of a plate heat exchanger according to the present invention.

[0031] like figure 1 and figure 2 As shown, the plate heat exchanger according to the present invention may include a casing 100 , a first supply line 200 , a first outflow line 300 , a second supply line 400 and a second outflow line 500 .

[0032] The casing 100 is a structure that integrally surrounds various structures for performing heat exchange of the heat medium in the plate heat exchanger according to the present invention, and in this embodiment, may include a plurality of plates that are stacked and arranged at regular intervals in the front...

no. 2 example

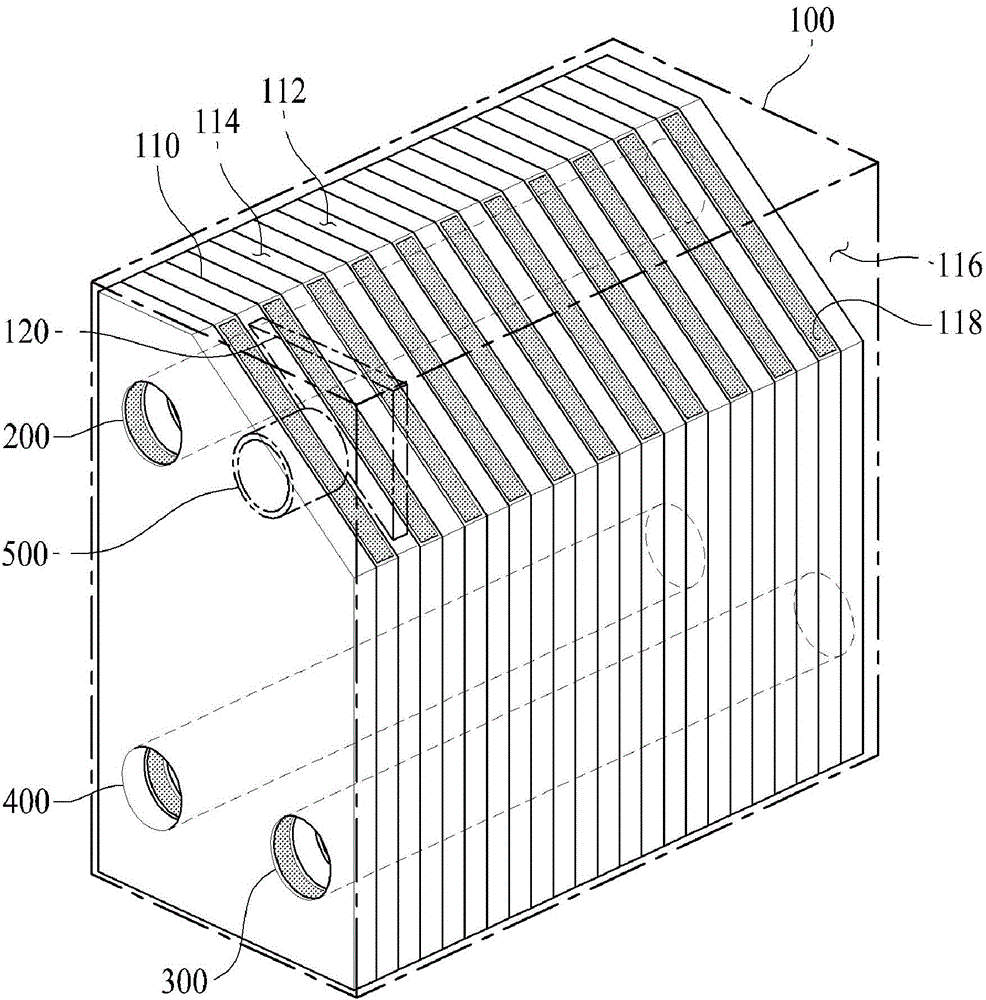

[0075] Next, refer to Figure 4 , the structure of the second embodiment of the plate heat exchanger according to the present invention will be described in detail.

[0076] in, Figure 4 is a drawing showing a second embodiment of the plate heat exchanger according to the present invention.

[0077] like Figure 4 As shown, the plate heat exchanger according to the present invention may include: plates 600 , a first supply line 700 , a first outflow line 800 , a second supply line 900 , a casing 1000 and a second outflow line 1100 .

[0078] Among them, the structures of the first supply line 700, the first outflow line 800, the second supply line 900 and the second outflow line 1100 and the above-mentioned first supply line 200 of the first embodiment of the plate heat exchanger according to the present invention, the first The structures of the outflow line 300 , the second supply line 400 and the second outflow line 500 are the same, and thus detailed descriptions there...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com