Overpressure connecting valve of household refrigerator

A technology for household refrigerators and conduction valves, which is applied in the directions of safety valves, balance valves, valve devices, etc., can solve the problems such as the inability to control the increase or decrease of the heat load of the compressor of the inverter refrigerator, the use of capillary tubes, and the failure to find them.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

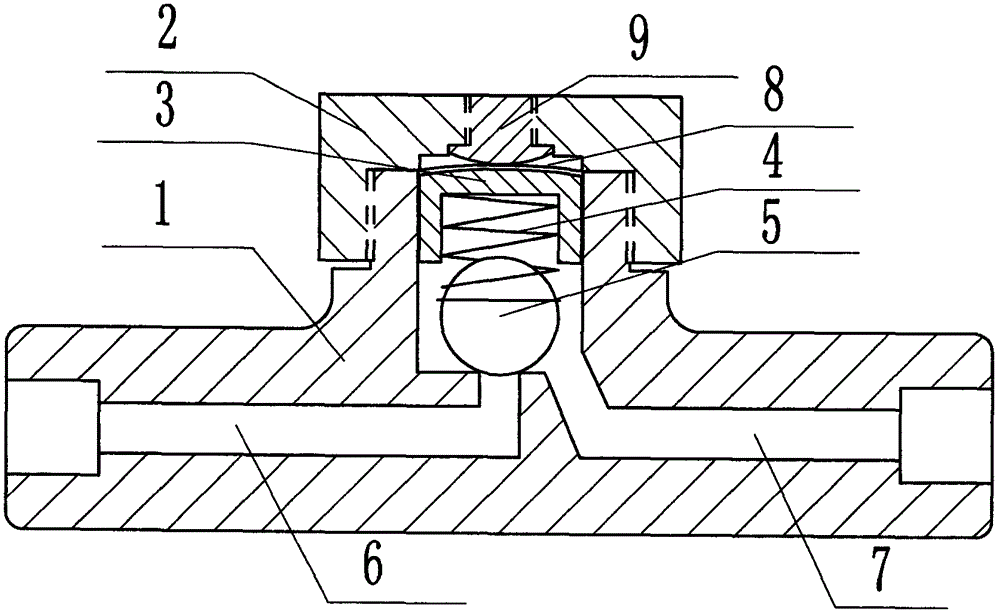

[0011] Such as figure 1 As shown, an overpressure conduction valve for household refrigerators includes a valve body 1, a sealing cover 2 installed on the valve body 1, a spring seat 3 is arranged between the sealing cover 2 and the valve body 1, and a spring seat 3 is installed on the spring seat There is a spring 4 on the 3, and the spring 4 is connected with a valve core 5. The valve body 1 has a liquid inlet channel 6 and a liquid outlet channel 7, and the valve core 5 is placed at the liquid outlet of the liquid inlet channel 6. Through the valve core 5 can open or close the liquid outlet of the liquid inlet channel 6 to communicate or disconnect the liquid inlet channel 6 and the liquid outlet channel 7; there is a sealing diaphragm 8 between the sealing cover 2 and the spring seat 3, and the sealing cover 2 A fine-tuning bolt 9 is provided, through which the position of the spring seat 3 can be fine-tuned.

[0012] The working principle of the present invention: the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com