Cone Pendulum Reducer with Small Tooth Difference

A deceleration device and a technology with less tooth difference, which is applied in the direction of gear transmission, transmission, transmission parts, etc., can solve the problems of high machining accuracy, complex structure, and difficulty, and achieve simple and compact structure and high transmission efficiency , The effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

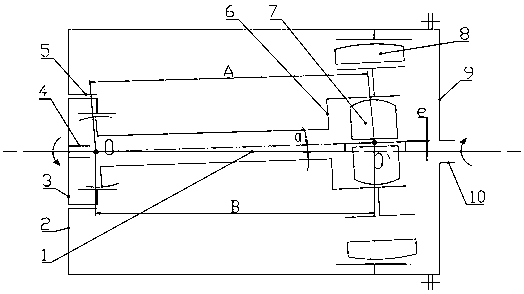

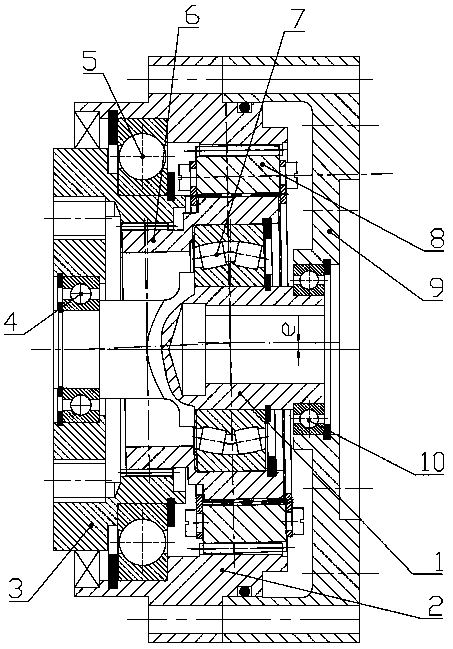

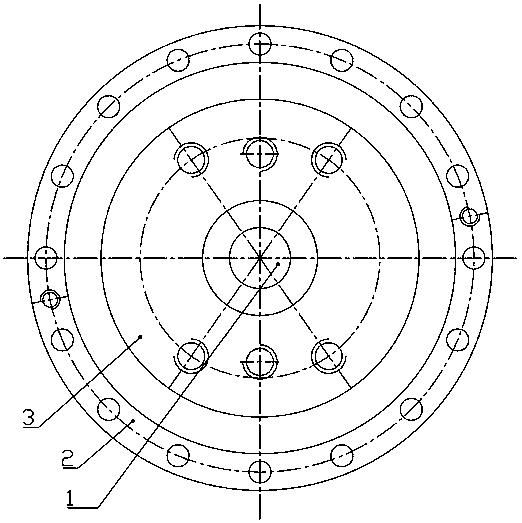

[0018] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0019] It includes a casing 2 that runs through both sides. The left side of the casing is connected to the output disk 3 with a ring gear on the inside through a bearing. The inner and outer circumference of the output disk is corresponding to the ring gear. The hole seats are arranged in phase, the outer peripheral diameter of the output disc is larger, and a sealing device is installed, and the outer end surface of the output disc is provided with a connecting screw hole. The right side of the casing is provided with a fixed ring gear, and a gear with ring gear 8 is installed in the fixed ring gear to form a swingable zero-tooth-difference gear coupling. The zero-tooth-difference gear coupling adopts an involute tooth shape. The outer teeth of the ring gear are drum gears. The right side of the casing is also connected with a connecting seat 9, the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com