Textile machine shock-absorbing seat with moving function

A technology of mechanical shock absorber and moving function, which is applied in the direction of spring/shock absorber, support machine, mechanical equipment, etc., which can solve the problems of increased adjustment difficulty, manufacturing difficulty, equipment bumping, etc., to achieve convenient height adjustment and reduce labor The effect that strength, manufacture is easy to lower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

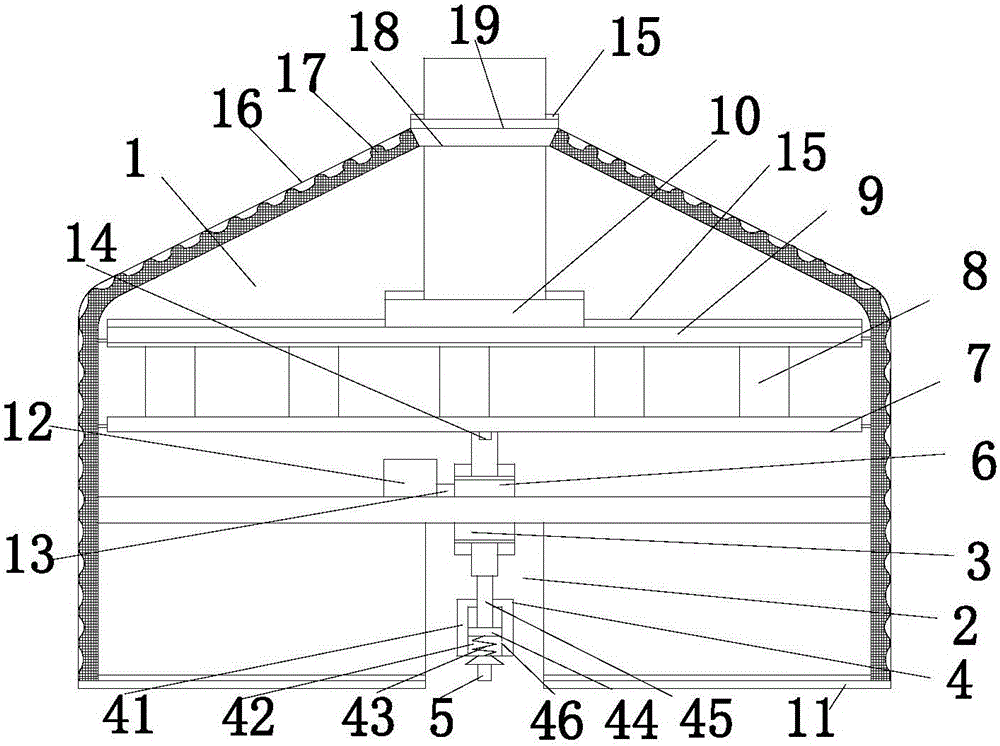

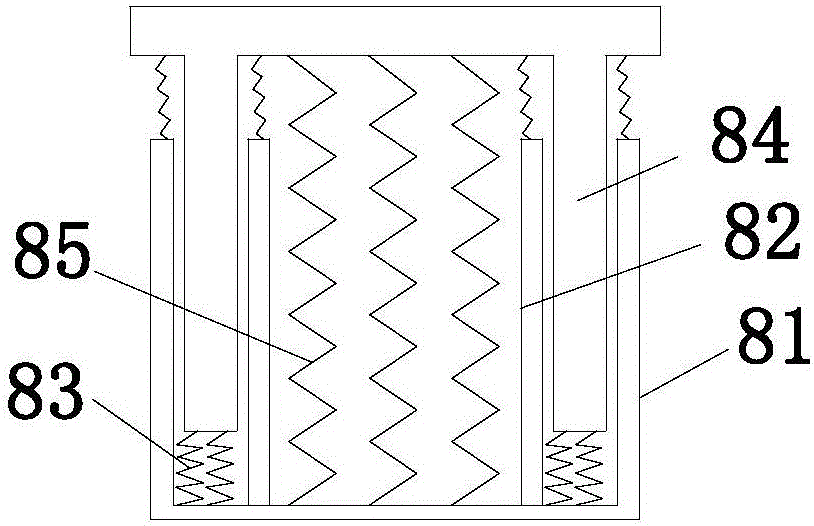

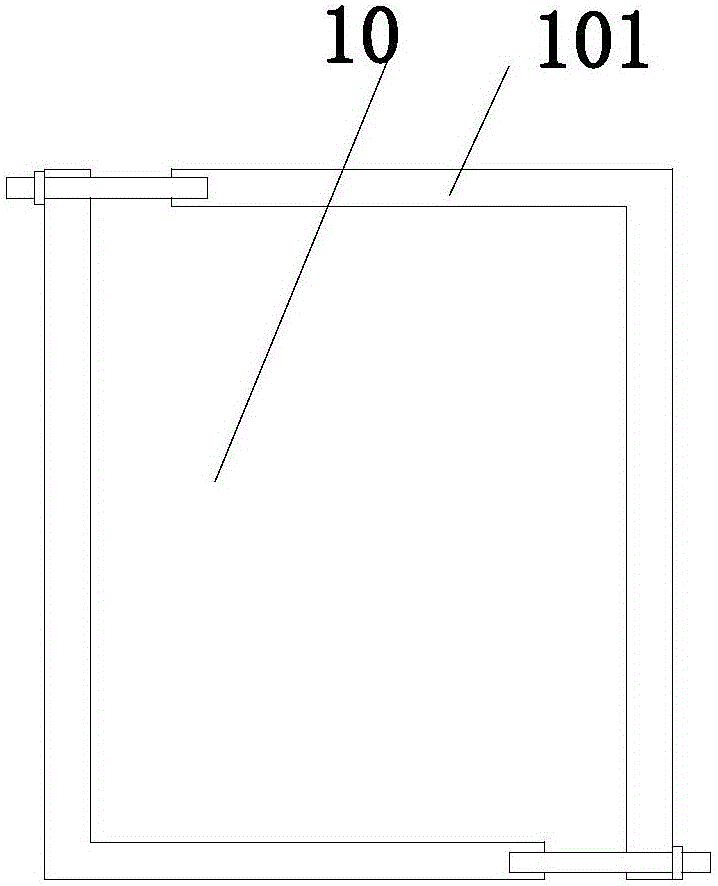

[0017] Embodiment: a kind of textile machine shock-absorbing seat with moving function, constitutes as figure 1 , figure 2 , image 3 and Figure 4 As shown, it includes a fixed seat 1, and the lower end of the fixed seat 1 is provided with an installation chamber 2, and a first hydraulic cylinder 3 is provided in the installation chamber 2, and the first hydraulic cylinder 3 is connected with a shock absorber 4, and a movable The wheel 5 is provided with a second hydraulic cylinder 6 in the fixed seat 1, and a first support plate 7 is provided on the extension end of the second hydraulic cylinder 6, and a plurality of circularly arranged shock absorbers 8 are provided on the first support plate 7. , a second support plate 9 is provided above the shock absorber 8, and a first clamp 10 is provided on the second support plate 9; the shock absorber 4 includes a housing 41, and an oil storage cylinder 42 is provided in the housing 41, and the oil storage cylinder 42 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com