A structure of a shield starting portal and a construction method for shield starting

A construction method and the technology of the starting hole, which is applied in the direction of earthwork drilling, wellbore lining, tunnel lining, etc., can solve the problems of inability to retain soil and water, difficult cutting of shield machine, and large loss of cutter head, etc., and achieve Reduce the scope of reinforcement, achieve sustainable development, and reduce the effect of construction expenditure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

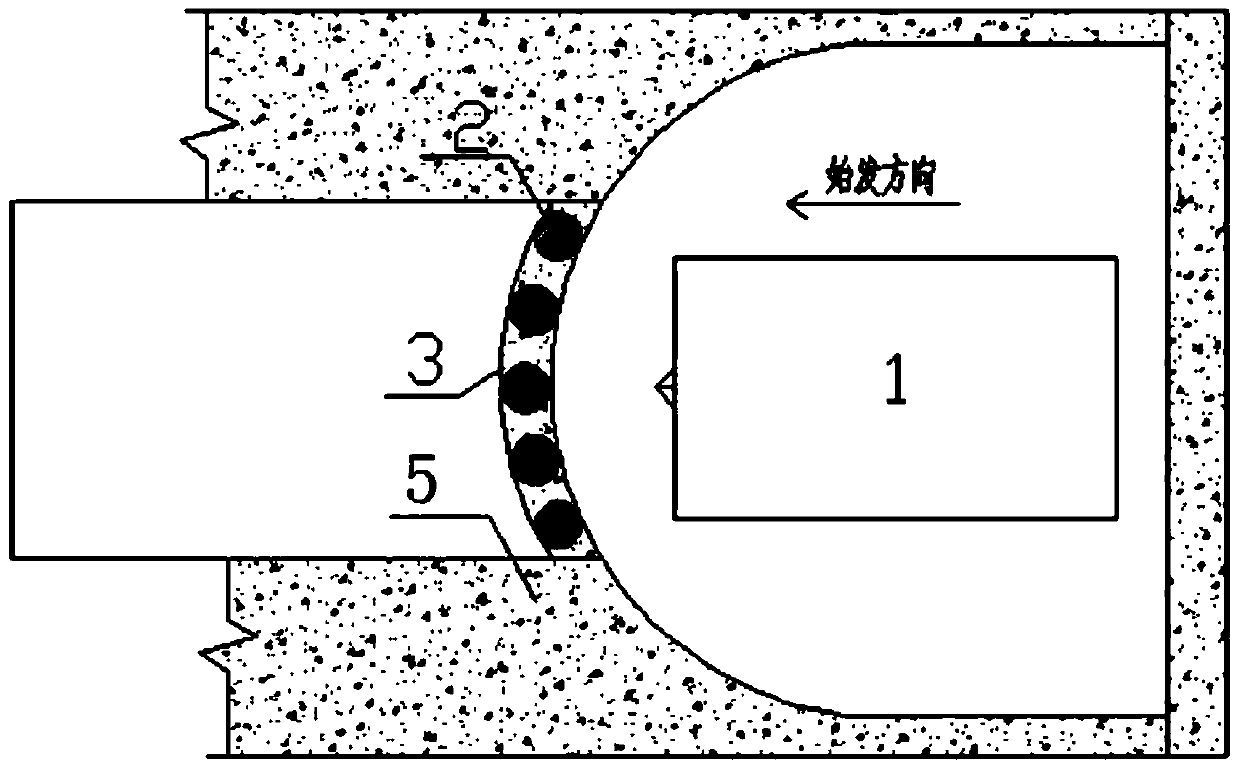

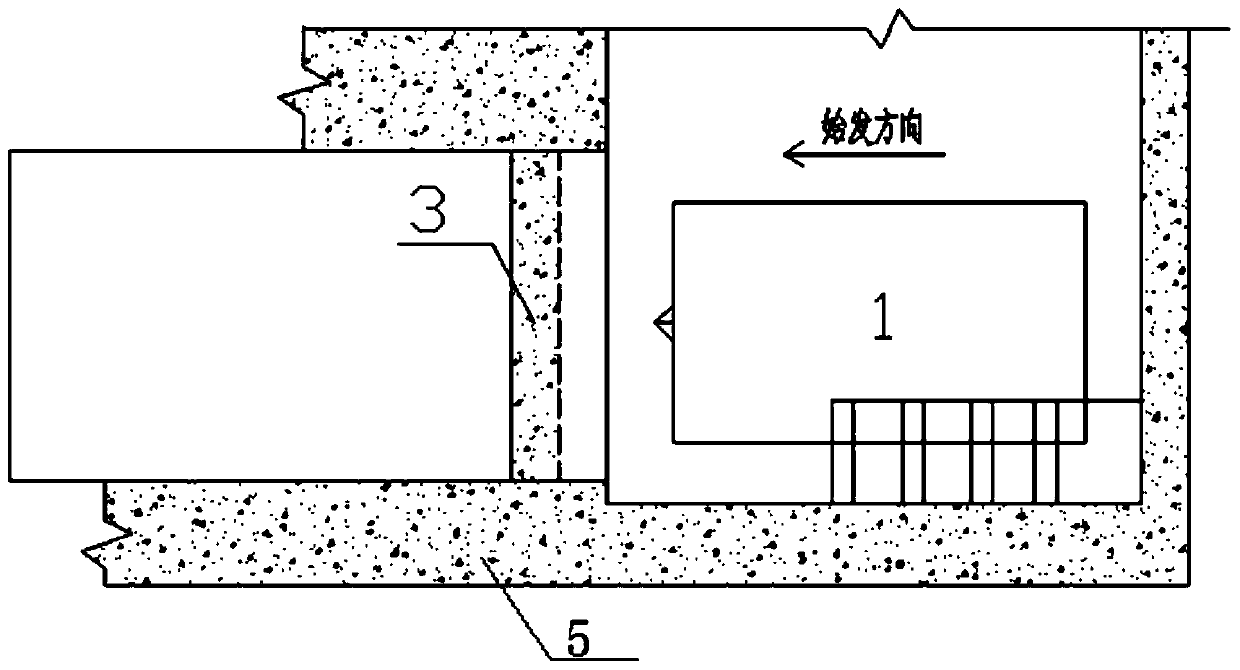

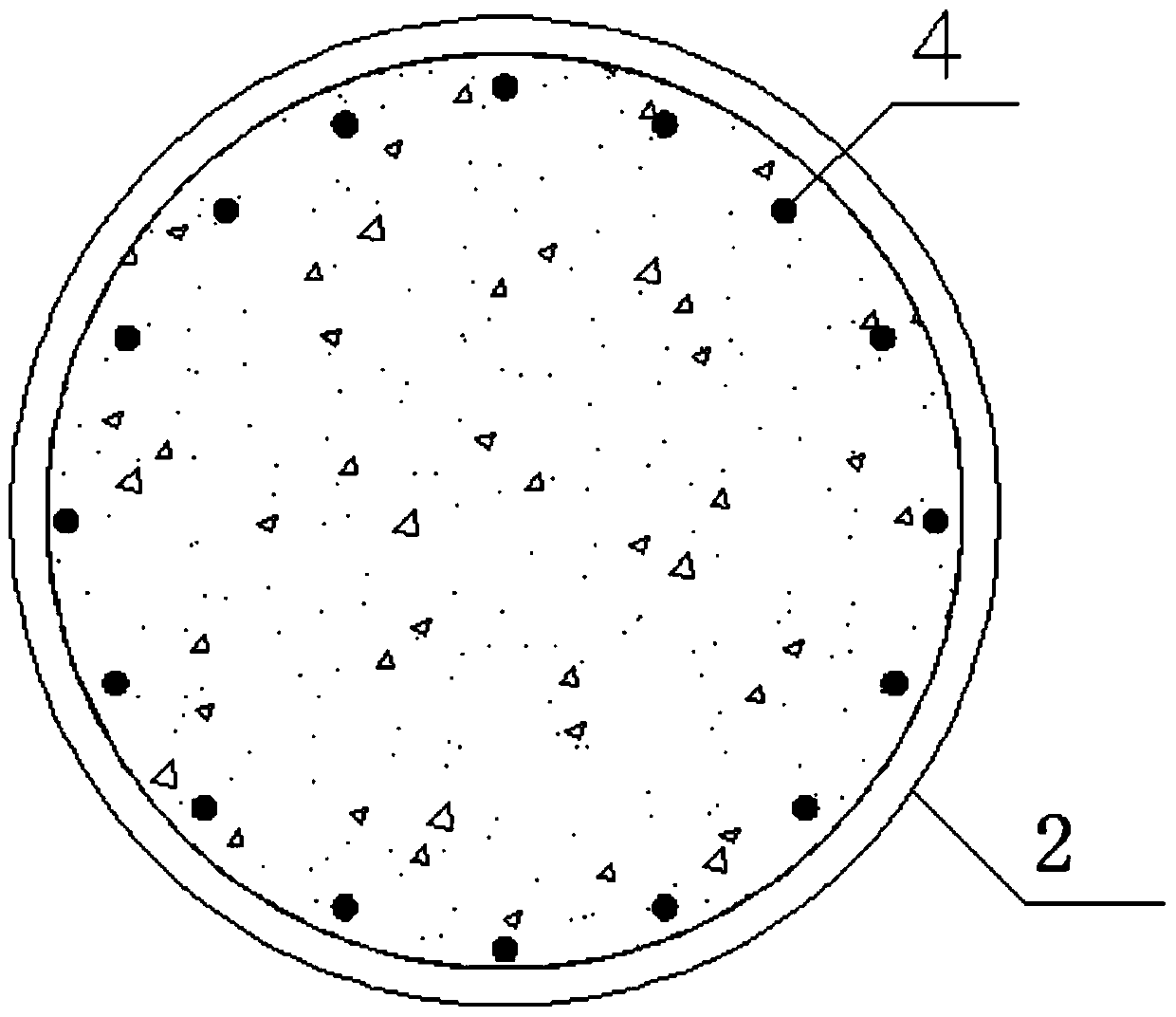

[0034] Such as figure 1 As shown in Fig. 1, the structure of the shield starting portal is mainly composed of arched plain concrete walls, and glass fiber reinforcement is used as an auxiliary reinforcement mode. It mainly includes the main structure 5 of the shield tunnel and the enclosure structure 3. The main structure 5 of the shield tunnel is made of plain concrete walls, and the shield tunnel is formed between the main structures 5 of the shield tunnel. The enclosure structure 3 is formed; the horizontal section of the enclosure structure 3 is arched, and the water and soil pressure outside the shield well is evenly distributed to the rock and soil strata outside the shield well; the enclosure structure 3 is evenly arranged with multiple glass Fiber reinforcement enclosure pile 2.

[0035] The main structure 1 of the shield well is arranged in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com