Electric iron tower deicing robot

A technology of power towers and robots, applied in the field of power grids, can solve the problems of broken towers, easy freezing of towers, and increased weight of the towers, and achieve the effects of strong tower climbing ability, high efficiency, and fast deicing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

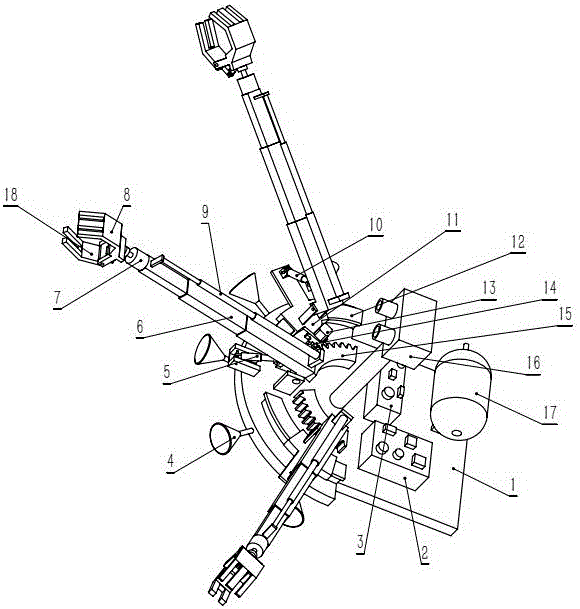

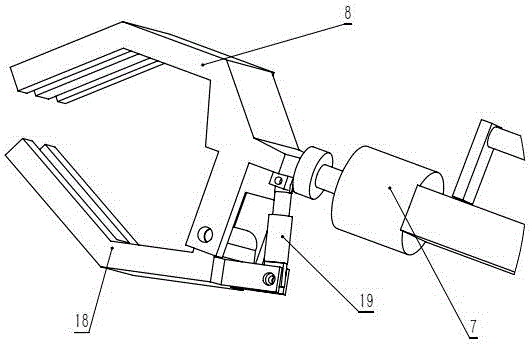

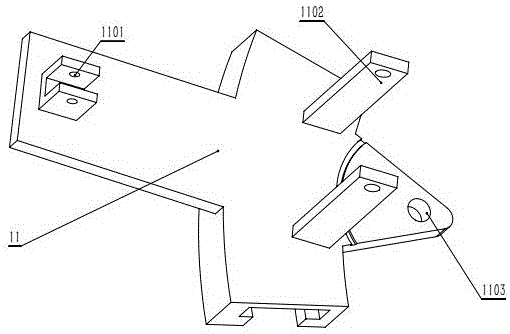

[0018] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, an electric tower deicing robot includes a frame 1, a hydraulic system 2, an electronic control system 3, a flame nozzle 4, a first hydraulic cylinder 5, a multi-stage telescopic arm 6, a servo motor 7, a fixed gripper 8. Multi-stage hydraulic cylinder 9, second hydraulic cylinder 10, sliding frame, guide rail 12, hydraulic motor 13, driving gear 14, driven gear 15, camera 16, liquefied gas tank 17, movable claw 18, third hydraulic cylinder 19, It is characterized in that: the front part of the frame 1 is semicircular arc shape, two arc-shaped guide rails 12 are provided on the upper surface of the frame 1, and a driven gear 15 is arranged inside the guide rail 12, and the guide rail 12 is connected with the slave The moving gear 15 is concentric; the sliding frame is slidably mounted on the guide rail 12, a first frame 1101 is arranged at the front end of the sliding frame, a second frame 1102 is arranged on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com