Transmission system used for slotting machine in water conservancy engineering

A technology of transmission system and water conservancy engineering, applied in the field of transmission system, to achieve the effect of reducing weight, compact structure and changing the direction of transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The accompanying drawing discloses the specific structure of an embodiment of the present invention without limitation, and the present invention will be further described below in conjunction with the accompanying drawings.

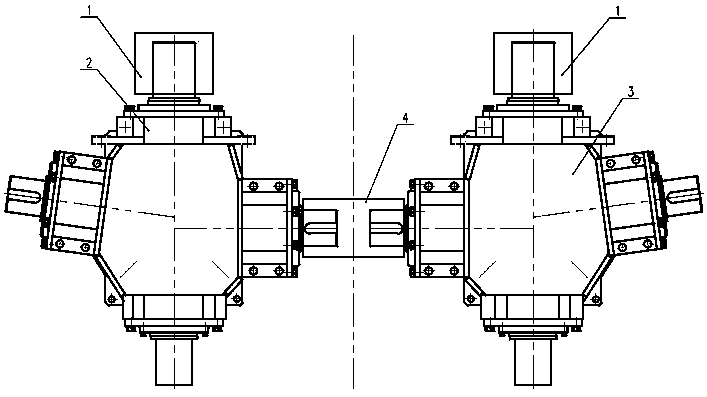

[0014] Depend on figure 1 It can be seen that the present invention includes a symmetrical left gearbox 2 and a right gearbox 3, both of which are equipped with independent hydraulic motors 1, and their synchronous shafts 8 are butted through a coupling 4. The hydraulic motor 1 drives the left gearbox 2 and the right gearbox 3 to rotate respectively, and the left gearbox 2 and the right gearbox 3 are connected through a shaft coupling 4 to realize synchronous load-sharing rotation.

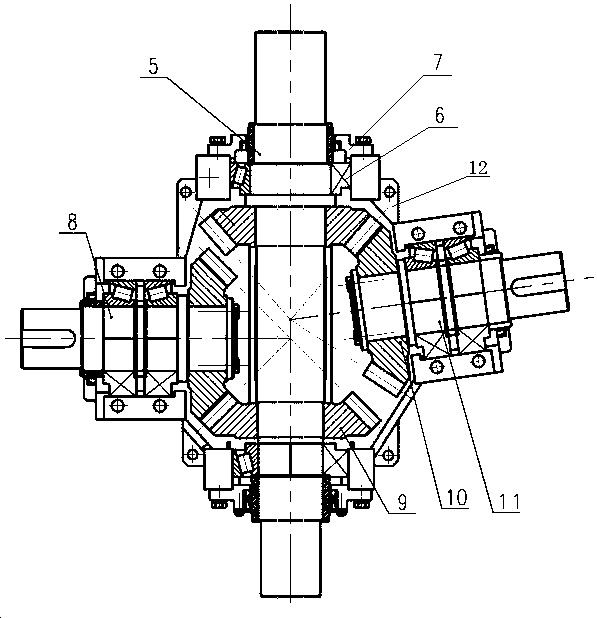

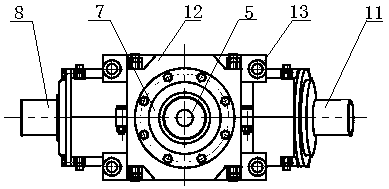

[0015] Depend on figure 2 It can be seen that the internal structure of the left / right gearbox (only the right gearbox is taken as an example) is: the left / right gearbox includes a box body 12, a drive shaft 5, a synchronous shaft 8, and a lateral output shaft 11, o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com