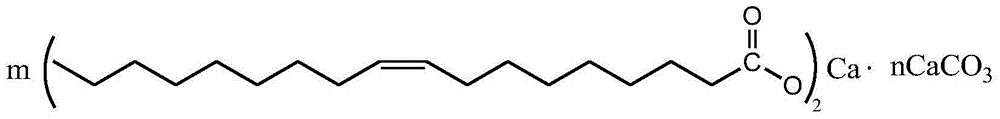

Alkaline oleate cleaning agent and preparation method thereof

A technology of oleate and detergent, which is applied in the field of lubricating oil, can solve the problems of product discoloration, easy oxidation and deterioration of linoleate, and easy oxidation and fracture of double bonds, etc., and achieves no biological toxicity, excellent high-temperature detergency, and appearance color shallow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] A preparation method of alkaline oleate detergent, comprising the following steps:

[0039] Step 1: Add organic solvent, alcohol accelerator, calcium hydroxide or calcium oxide and water into a flask equipped with electric stirrer, thermometer and condensation dehydrator, turn on the stirrer, raise the temperature to 30-40°C, and stir evenly Finally, add oleic acid and base oil to carry out neutralization reaction, maintain the reaction temperature at 40-60°C, and maintain the neutralization reaction time for 0.5h-1h;

[0040] Step 2: After the neutralization reaction is completed, pass carbon dioxide gas into the flask at a ventilation rate of 200-250mL / min, carry out a high alkalinity reaction for 2 hours, and maintain the reaction temperature at 40-60°C;

[0041] Step 3: After the high alkalinity reaction is completed, heat the mixture to 110-130°C, remove the alcohol accelerator and water, then cool down to 60-80°C, add the organic solvent used in step 1 to dilute, ...

Embodiment 1

[0057] Add 120mL of straight-run gasoline and 120mL of methanol (industrial product) into a 500mL four-necked flask equipped with an electric stirrer and a condensing dehydrator, start stirring and heat up, then add 32.0g of calcium hydroxide (industrial product) and 10.0g of water, Raise the temperature to 30-40°C, then add 50.0g of tallow oleic acid (industrial product) and 50.0g of HVI150 base oil to carry out neutralization reaction. It can be seen that the reaction system becomes thicker, accompanied by obvious temperature rise. Control the reaction temperature at 45- At 55°C, the neutralization reaction was maintained for 1.0h. After that, carbon dioxide gas was introduced at a certain rate (controlling the ventilation rate to 200-250mL / min) for high alkalinity reaction. The appearance color of the system gradually changed from milky white to light yellow, and the high alkalinity reaction was maintained for about 2.0 hours. After the reaction, Raise the temperature to 11...

Embodiment 2

[0059] Add 120mL of straight-run gasoline and 120mL of methanol (industrial product) into a 500mL four-necked flask equipped with an electric stirrer, a thermometer and a condensation dehydrator, start stirring and raise the temperature, then add 35.0g of calcium hydroxide (industrial product) and 10.0 g of water g, heat up to 30-40°C, then add 50.0g of vegetable oleic acid (industrial product), 50.0g of HVI150 base oil, and carry out neutralization reaction. It can be seen that the reaction system becomes thicker, accompanied by temperature rise, and the reaction temperature is controlled at 45 ~55°C, keep the neutralization reaction for 1.0h. After that, carbon dioxide gas was introduced at a certain rate (controlling the ventilation rate to 200-250mL / min) for high alkalinity reaction. The appearance color of the system gradually changed from milky white to light yellow, and the high alkalinity reaction was maintained for about 2.0 hours. After the reaction, Raise the temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com