Method and device for preparing fuel by means of mixing coke powder with sludge from sewage plants

A technology of mixing device and sewage plant, applied in the field of comprehensive utilization of solid waste resources, can solve the problems of poor sludge resource utilization, low sludge addition, regional environmental pollution, etc. The effect of large and large sludge treatment capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] First, mix 1 kg of sludge from urban domestic sewage plants with 1 kg of waste coke powder produced by the coking industry for 15 minutes; then add 0.2 kg of lime to the mixed material to digest and dry the sludge; then perform compression molding with a molding pressure of 200 kg / cm 2 , and then kept at room temperature for 12 hours to obtain about 2kg of environmentally friendly solid fuel. The obtained environmentally friendly solid fuel was tested according to the national standard solid biomass fuel calorific value determination method (GB / T30727-2014), and its high calorific value was 18.9MJ / kg.

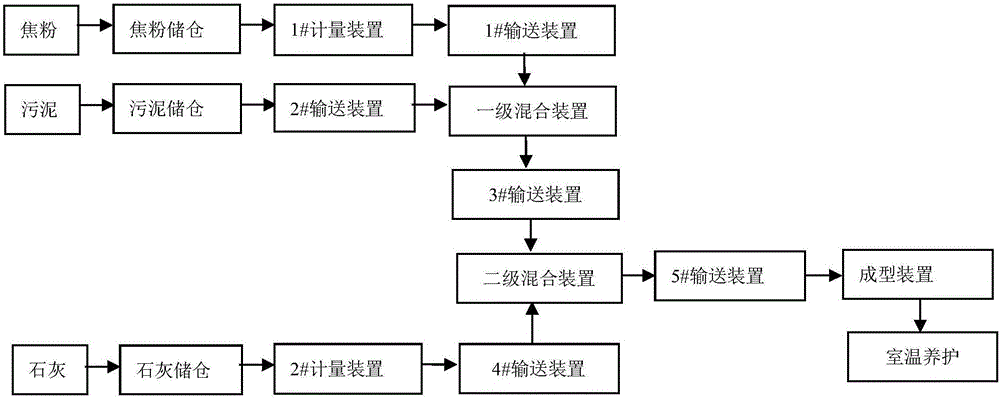

[0034] A device for preparing fuel by mixing sewage plant sludge and coke powder, which uses the method described in Example 1, and the equipment flow chart is as follows figure 1 Shown: the waste coke powder produced by the coking industry is stored in the coke powder storage bin, the sludge generated by the sewage plant is stored in the sludge storage bin, and the lime...

Embodiment 2

[0037] First, mix 1 kg of sludge from urban domestic sewage plants with 4 kg of waste coke powder produced by the coking industry for 10 minutes; then add 0.25 kg of lime to the mixed material to digest and dry the sludge; then perform compression molding with a molding pressure of 100 kg / cm 2 , and then kept at room temperature for 8 hours to obtain about 5kg of environmentally friendly solid fuel. The obtained environmentally friendly solid fuel was tested according to the national standard solid biomass fuel calorific value determination method (GB / T30727-2014), and its high calorific value was 23.3MJ / kg.

Embodiment 3

[0039] First mix 1.2kg of urban domestic sewage plant sludge with 0.8kg of waste coke powder produced by the coking industry for 30 minutes; then add 0.16kg of lime to the mixed material for sludge digestion and drying; then perform compression molding with a molding pressure of 1000kg / cm 2 , and then kept at room temperature for 24 hours to obtain about 1.9kg of environmentally friendly solid fuel. The obtained environmentally friendly solid fuel was tested according to the national standard solid biomass fuel calorific value determination method (GB / T30727-2014), and its high calorific value was 17.8MJ / kg.

[0040] The advantage of the present invention is that according to the principle of "efficient recycling of resources, green and environmental protection", the municipal sludge and coke powder are directly mixed and granulated to prepare solid fuel, and the "turning waste into treasure" of municipal sludge and the efficient utilization of resources are truly realized. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com