A method for starting up a gasifier to meet oxygen

A technology of gasification furnace and oxygen, which is applied in the direction of gasification process, manufacture of combustible gas, petroleum industry, etc., to achieve the effect of reliable operation, reduced operation risk, and simple process configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

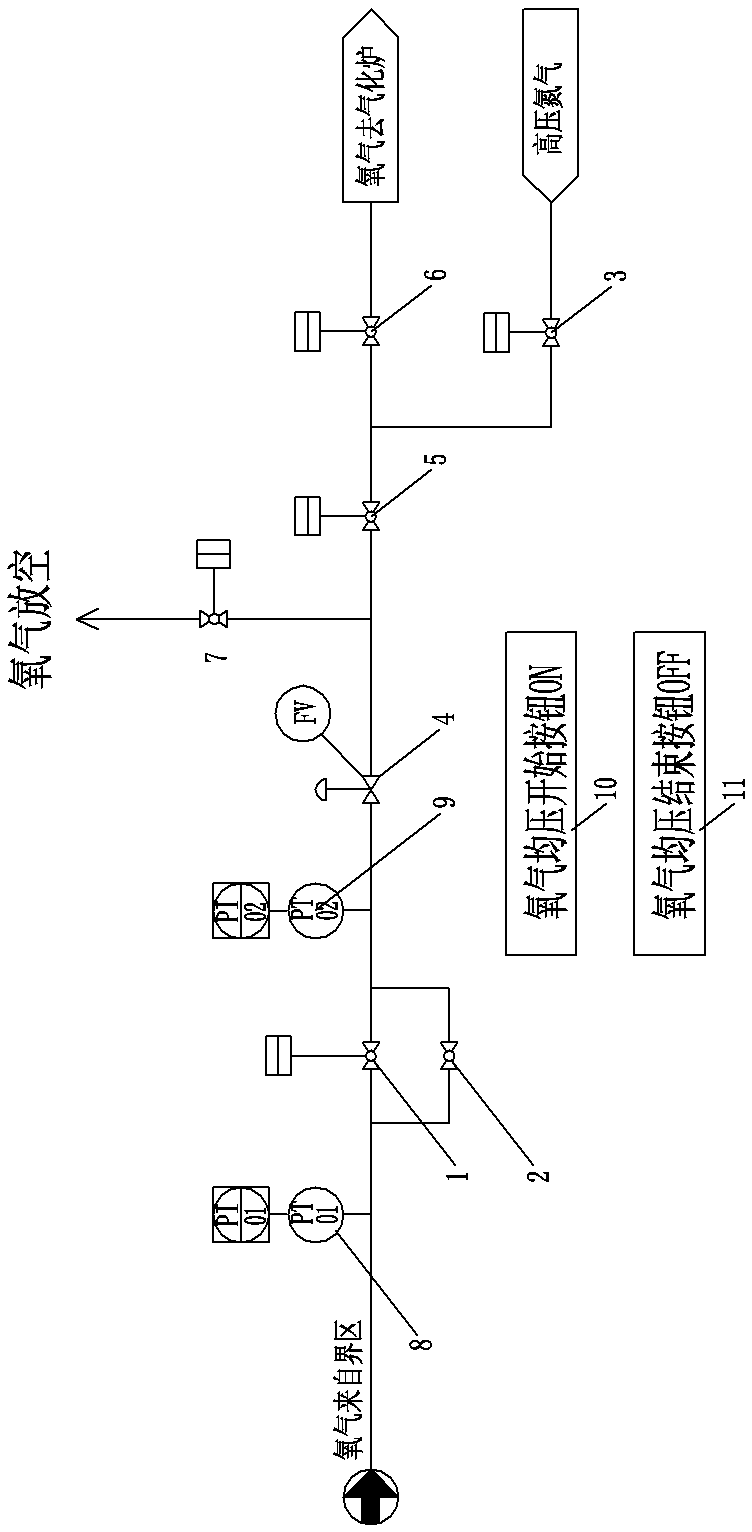

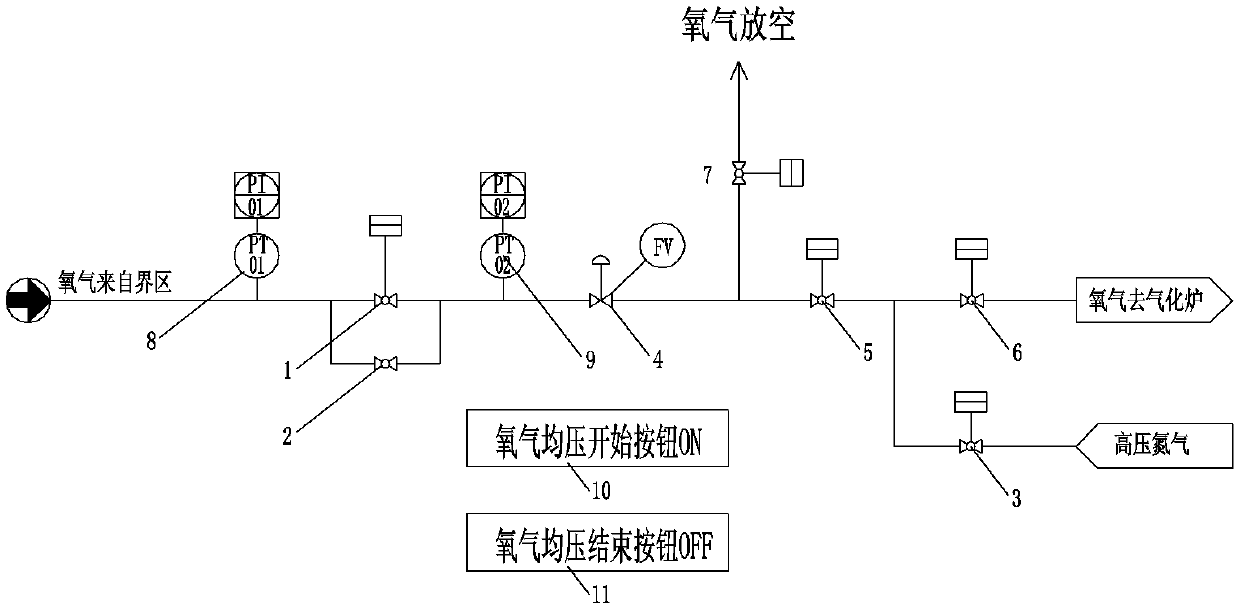

[0018] A system diagram of an embodiment of the present invention is shown in figure 1 As shown, the method for starting up the gasifier to meet oxygen in this embodiment includes the following steps: 1) Establishing a pressurized pipeline: an oxygen pipeline is set between the oxygen boundary zone and the gasifier, and oxygen boundary zones are sequentially set on the oxygen pipeline Valve 1, oxygen flow control valve 4, oxygen upstream nitrogen plug valve 5 and oxygen downstream nitrogen plug valve 6, an oxygen pressure equalizing valve 2 connected in parallel with the oxygen boundary valve 1 is set on the oxygen pipeline, and an oxygen flow control valve is located on the oxygen pipeline. An oxygen venting pipeline is set between the valve 4 and the oxygen upstream nitrogen plug valve 5, an oxygen venting valve 7 is set on the oxygen venti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com