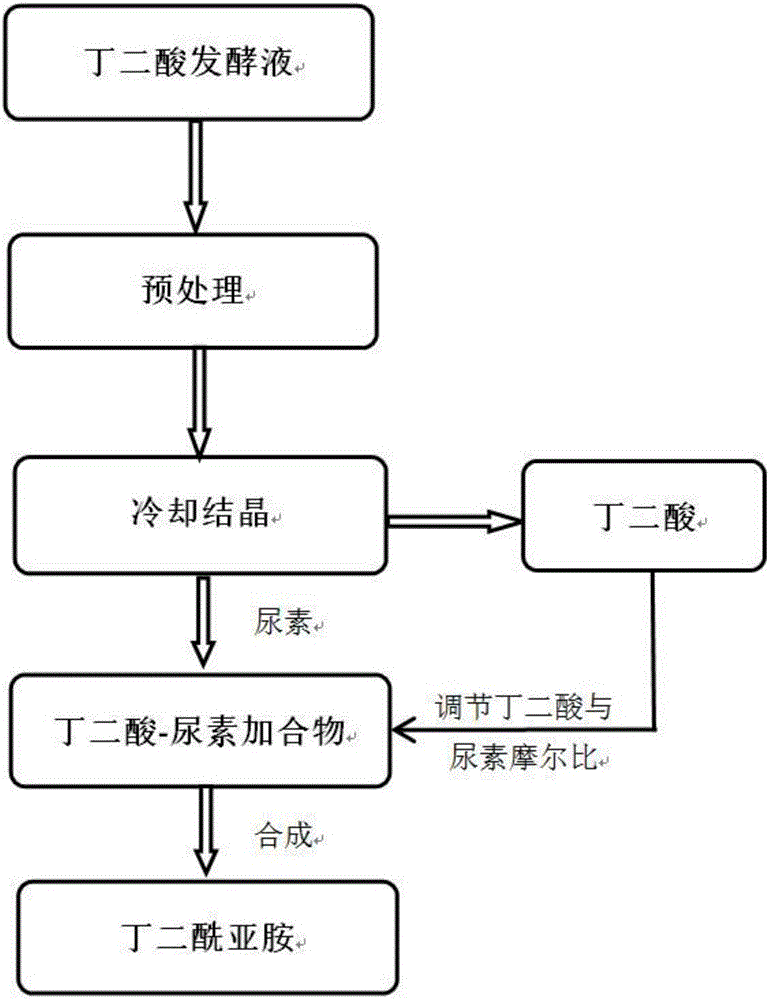

Method for preparing succinimide with succinic acid fermentation liquor

A technology of succinimide and succinic acid, applied in the direction of organic chemistry, can solve the problems of pollution, high raw material cost, high energy consumption, etc., and achieve the effects of being environmentally friendly, less polluting, and simplifying the operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044]The fermentation broth fermented by the succinic acid-producing Escherichia coli genetically engineered bacteria was centrifuged and filtered, and then decolorized through an activated carbon decolorization column to obtain 1 L of clarified succinic acid fermentation broth. After the pretreated fermentation broth was acidified to adjust the pH<2 (the concentration of succinic acid was 105.37g / L), it was placed in a cooling crystallization tank at 4°C for 12 hours to crystallize. Filtrate to obtain the succinic acid solid (73.6 g of succinic acid obtained by vacuum drying) and the filtered mother liquor of succinic acid crystals. Add 85.2 g of urea to the filtered mother liquor of succinic acid crystallization, heat and stir to dissolve, then cool down to 4° C. for cooling and crystallization for 12 hours to obtain 56.8 g of urea succinic acid cocrystal after drying. Then the co-crystal was added to the reactor, and 73.6 g of succinic acid obtained by cooling and crystall...

Embodiment 2

[0046] The fermentation broth fermented by the succinic acid-producing Escherichia coli genetically engineered bacteria was centrifuged and filtered, and then decolorized through an activated carbon decolorization column to obtain 1 L of clarified succinic acid fermentation broth. Then acidify the pretreated fermented liquid to adjust the pH<2 (the concentration of succinic acid is 106.17g / L), put it into a cooling crystallization tank at 4° C. for 12 hours to crystallize. Filtrate to obtain succinic acid solid (73.7 g succinic acid obtained by vacuum drying) and succinic acid crystals and filtered mother liquor. Add 90 g of urea to the filtered mother liquor of succinic acid crystallization, heat and stir to dissolve, and then cool down to 4° C. for cooling and crystallization for 12 hours to obtain a co-crystal of urea succinate with a mass of 58.3 g after drying. Then put the co-crystal into the reaction kettle, add 73.7g of succinic acid obtained by cooling and crystalliza...

Embodiment 3

[0048] The fermentation broth fermented by the succinic acid-producing Escherichia coli genetically engineered bacteria was centrifuged and filtered, and then decolorized through an activated carbon decolorization column to obtain 1 L of clarified succinic acid fermentation broth. After the pretreated fermentation broth was acidified to adjust the pH<2 (the concentration of succinic acid was 103.25 g / L), it was cooled and crystallized at 4° C. for 12 hours, and the dried mass of succinic acid solid was 72.3 g. Then 100g of urea was added to the mother liquor after crystallization, heated and stirred to dissolve, and then cooled to 8°C for 12 hours to cool and crystallize to obtain a co-crystal of urea succinate with a mass of 55.4g after drying. Then 55.4g of co-crystals were added to the reaction kettle, 70g of succinic acid was added, and 1.2g of phosphorous acid solid was added, stirring was started and the temperature was raised to 135°C for 1 hour, and the temperature was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com