Wastewater treatment device based on carbon nanotube/zinc oxide PTFE photocatalytic membrane and application thereof

A carbon nanotube, photocatalytic membrane technology, applied in energy wastewater treatment, water/sewage treatment, special compound water treatment, etc., can solve the problems of photocorrosion, limit the application of ZnO, etc. The effect of market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

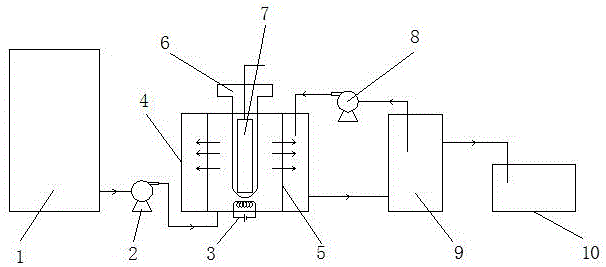

[0026] Wastewater treatment devices based on carbon nanotubes / zinc oxide PTFE photocatalytic membranes, such as figure 1 As shown, it includes a water inlet system, a photocatalytic system, a distillation system, a circulating water system and a water collection system connected in sequence by pipelines. The photocatalytic system includes a quartz cold trap 6 and a light source 7, and the light source 7 is placed in the quartz cold trap 6; the distillation system includes a heater 3, a membrane still 4, a carbon nanotube / zinc oxide PTFE photocatalytic film 5, and the carbon nanotube / zinc oxide PTFE photocatalytic film 5 is made into the shape of a cylinder side, and the photocatalytic system located on the central axis. The water intake system includes a wastewater tank 1 and a water intake pump 2 , the circulating water system includes a circulating water pump 8 and a circulating pool 9 ; the water collection system includes a sump 10 .

[0027] In this embodiment, the pheno...

Embodiment 2

[0029]In this example, dimethyl disulfide wastewater with a concentration of 40 mg / L is used as the target pollutant, and an ultraviolet lamp with a wavelength of 254 nm is used as the light source. The temperature of the hot side of the membrane still-3 is set to 60 ° C, and the temperature of the cold side is room temperature. , the hydraulic retention time is set to 3h, turn on the water inlet pump-2 with a liquid level controller, and the circulating water pump-8 to circulate the hot and cold side water of the membrane distiller, take a sample every 0.5h, and measure the sump-10 The concentration of dimethyl disulfide and COD value in the medium, found that the removal rate of dimethyl disulfide and COD can reach 95%. After the membrane used up in the experiment is ultrasonically cleaned with distilled water for 5-6 hours, the flux of the membrane can be restored to more than 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com