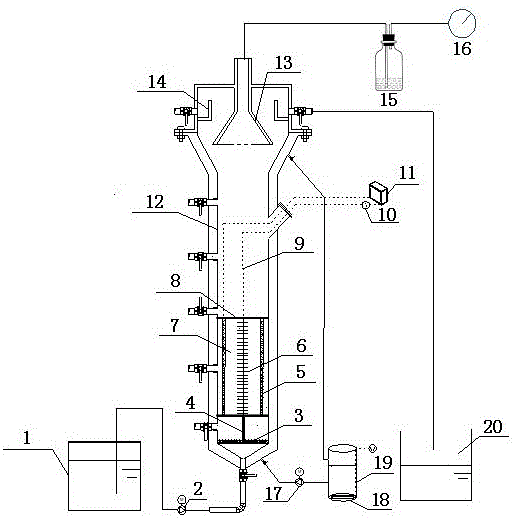

Magnetite-enhanced biological electrode coupled UASB (upflow anaerobic sludge bed/blanket) apparatus and operation method

A bio-electrode, magnetite technology, applied in biological treatment devices, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problem of insignificant power-on effect, low biomass on the electrode surface, anodic oxidation efficiency, and electron transfer efficiency. It can improve the pollutant removal performance, promote the sludge granulation process, and strengthen the anaerobic sludge granulation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of described magnetite nanoparticles is as follows: configure 0.3molL with deoxygenated ultrapure water -1 H 2 SO 4 Solution 200mL, add Fe 2 (SO 4 ) 3 ·xH 2 O (6.4g) and FeSO 4 ·7H 2 O (4.45g) was stirred to dissolve. Add the mixed solution drop by drop to 250mL, 1.5mmolL -1 In the sodium hydroxide solution, stir vigorously at the same time to make it fully react, and a black precipitate of magnetite will be produced immediately at this time. Place a magnet near it to speed up the separation of the suspension, then discard the supernatant. The black precipitate was washed with deoxygenated ultrapure water and centrifuged at 4000 rpm, and this operation was repeated three times. Finally, the black precipitate was added to 0.25L deoxygenated ultrapure water to form a magnetite colloidal solution.

[0025] A kind of operation method of described device magnetite strengthening biological electrode coupling type UASB device, comprises the fo...

Embodiment

[0030]Use the above device to start the anaerobic reactor, and run three sets of anaerobic reactors, R1 is a magnetite-bioelectrode coupled UASB reactor, R2 is a bioelectrode coupled UASB reactor, R3 is a conventional UASB reactor, The R1 and R2 reactors were applied with 1.5V voltage, except that other reaction conditions were the same. The inner diameter of the upper part of the UASB reactor is 19cm, the inner diameter of the lower part is 11cm, the height is 50cm, the total volume is 6.6L, and the effective volume is 6.38L.

[0031] The start-up phase of the R1 reactor is as follows:

[0032] 1) Take the anaerobic activated sludge that has been domesticated and cultivated, add 1L nano-magnetite colloidal solution to it, and mix well. Inoculation sludge concentration MLSS is 44.57gL -1 , MLVSS is 16.61gL -1 ; After the reactor was started, the Fe concentration was finally 3.37gL -1 , equivalent to 0.5gFeg -1 MLVSS.

[0033] 2) Inoculate the mixed sludge obtained in ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com