Hemispherical magnetic pole electro-permanent magnet lifting jack capable of attracting curved surface workpieces

A curved surface workpiece and hemispherical technology, applied in the field of hemispherical magnetic pole electro-permanent magnetic lifter, can solve the problems of cumbersome operation, time-consuming, unable to hold, etc., and achieve the effect of safe and reliable operation, reduced production cost and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

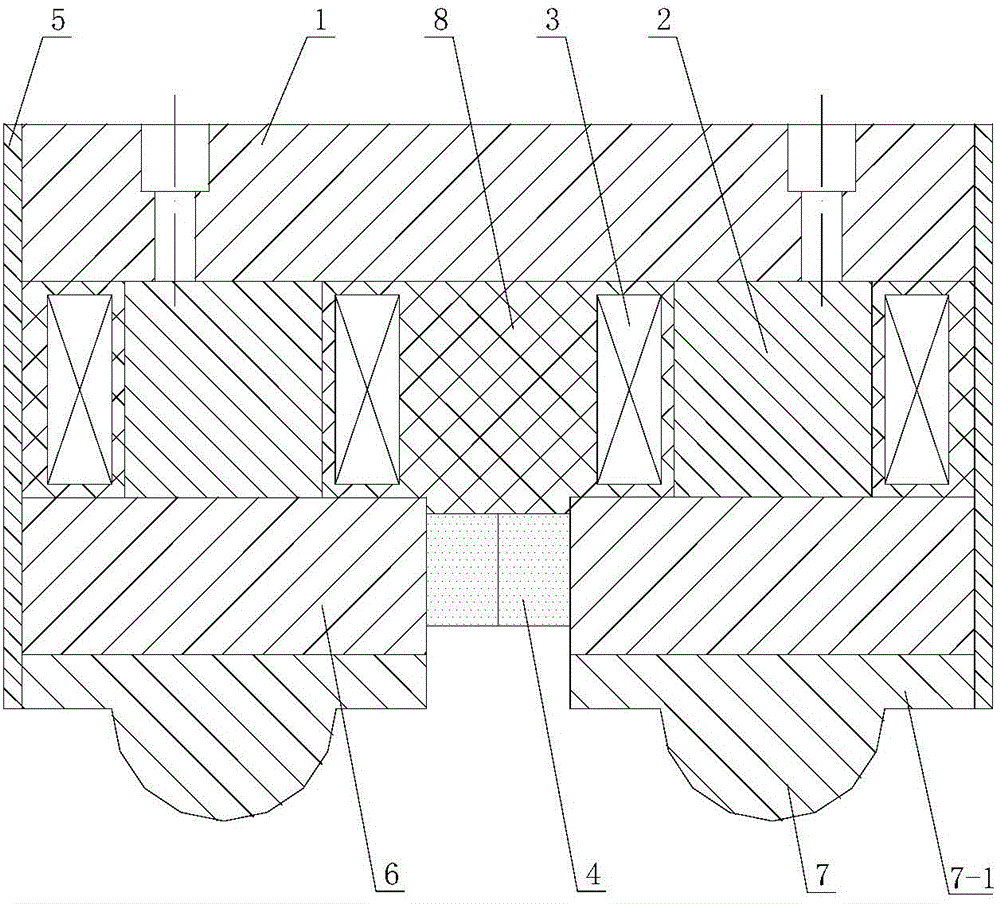

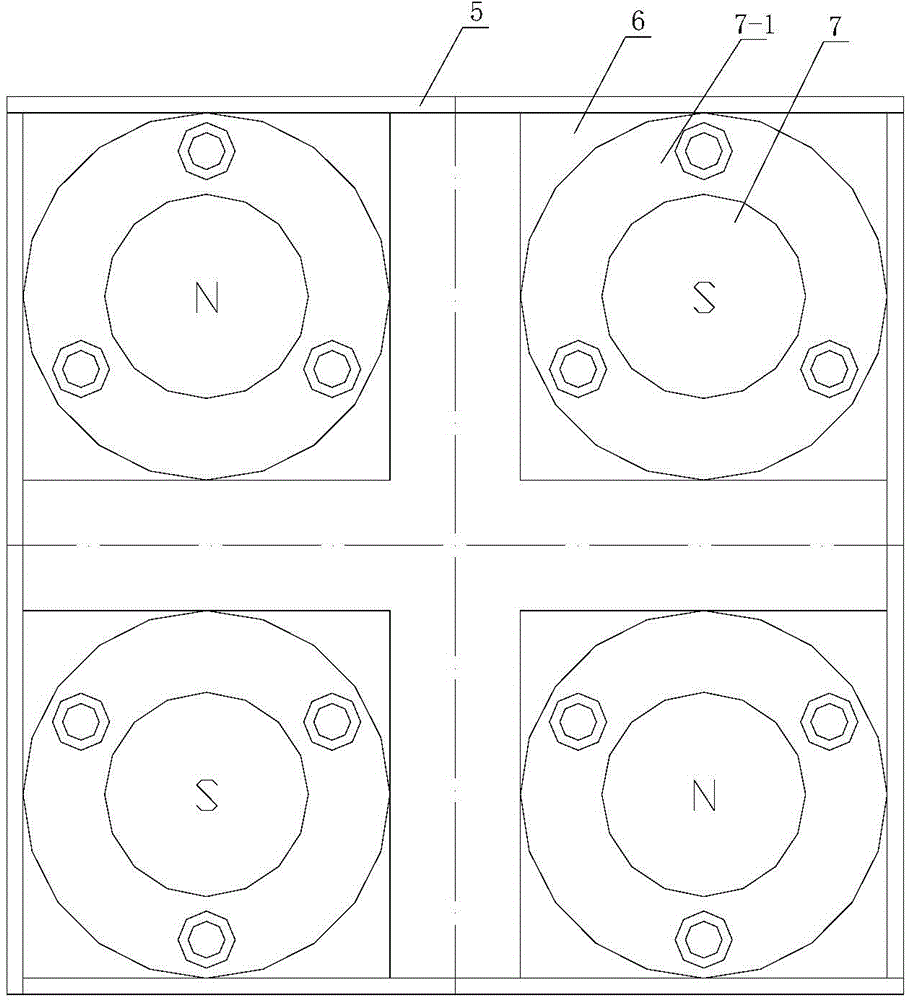

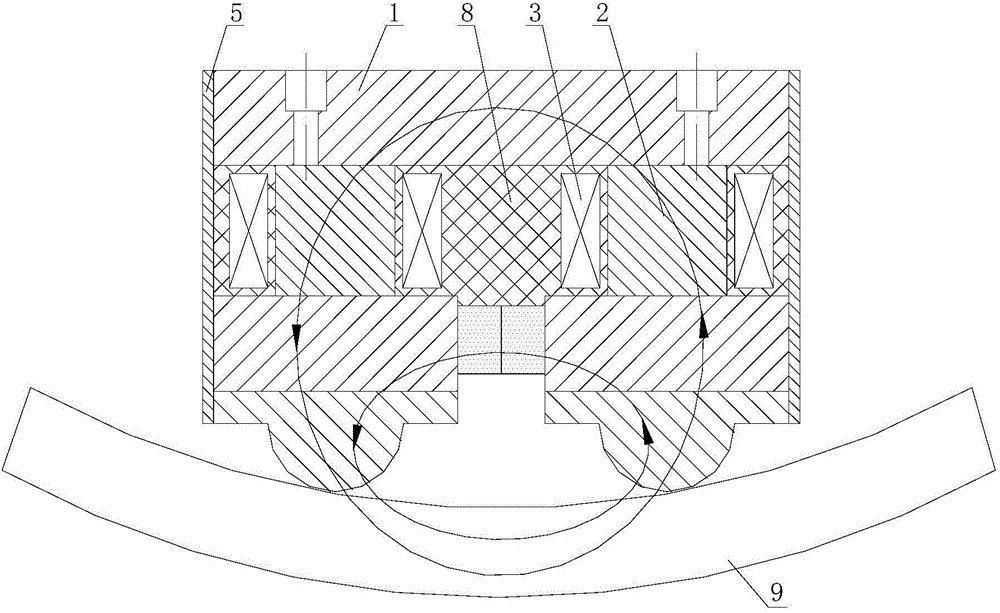

[0015] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0016] see figure 1 with figure 2 , a hemispherical magnetic pole electric permanent magnet lifter that can attract curved workpieces, including a base plate 1 made of low-carbon steel, on which a reversible magnet 2 is installed, and a coil 3 is set on the outer ring of the reversible magnet. The top of the reversible magnet is equipped with a plurality of armatures 6, and the main magnet 4 is embedded between the armatures. The non-magnetic metal plate 5 is packaged on the outer surface of the bottom plate and the armature, and resin 8 is poured between the reversible magnet, the coil and the main magnet. . The top of each armature 6 is fixed with a hemispherical magnetic pole 7 that can meet the needs of different curvature surfaces.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com