Magnesium alloy wheel hub

A technology of magnesium alloy and wheel hub, which is applied in the field of magnesium alloy wheel hub, can solve the problems that the stress cannot meet the requirements of use and the maximum stress of the aluminum alloy wheel hub is large.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

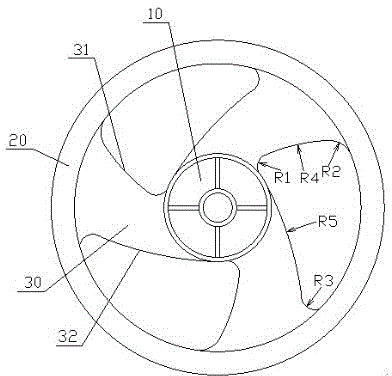

[0020] Examples, see figure 1 As shown: a magnesium alloy wheel hub, including a wheel core 10 and a rim 20 , and a spoke 30 is provided between the wheel core 10 and the rim 20 . At the same time, the spoke 30 includes an inner arc edge 31 and an outer arc edge 32, and the inner arc edge 31 has a fourth arc R4, the inner arc edge 31 and the wheel core 10 have a first arc R1, and the rim 20 There is a second arc R2 between them, the outer arc 32 has a fifth arc R5, and there is a third arc R3 between the outer arc 32 and the rim 20 . Wherein, the value ranges of the first radian R1, the second radian R2, the third radian R3, the fourth radian R4, and the fifth radian R5 are respectively: 20mm≤R1≤30mm, 10mm≤R2≤15mm, 10mm≤R3≤ 15mm, 300mm≤R4≤310mm, 330mm≤R5≤360mm. Optimally, the value ranges of the first radian R1, the second radian R2, the third radian R3, the fourth radian R4, and the fifth radian R5 are respectively: R1=24.45mm, R2=13mm, R3=13mm, R4 =307.5mm, R5=350mm. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com