Tool storage rack

A technology for placing racks and knives, applied in tool storage devices, manufacturing tools, etc., can solve the problems of multiple handling, limited number of knives placed, inconvenient tool replacement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

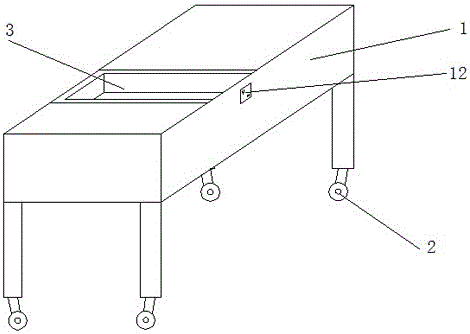

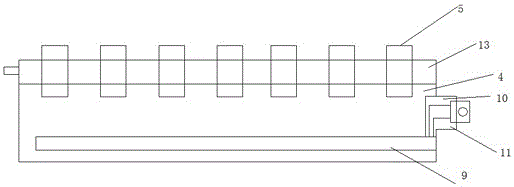

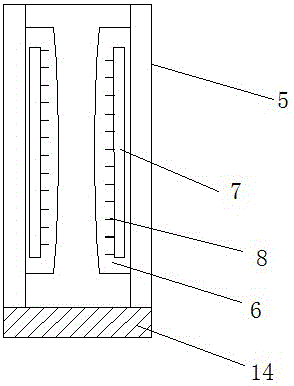

[0024] Such as figure 1 , figure 2 with image 3 As shown, a tool placement rack includes a frame 1, a pulley 2 is provided at the bottom of the frame 1, a placement groove 3 is provided on the frame 1, a tool placement box 4 is arranged in the placement groove 3, and the tool placement box 4 There is an accommodation cavity 5 in the interior, and a sponge pad 6 is attached to the accommodation cavity 5. An oil bag 7 is arranged in the sponge pad 6, and the oil bag 7 is filled with antirust oil. The surface layer of the oil bag 7 is attached with some antirust thin tube of oil8.

[0025] An electromagnet 9 is arranged below the accommodating cavity 5 , and the electromagnet 9 is connected to an external power source through the connection between the tool placement box 4 and the placement slot 3 .

Embodiment 2

[0027] To further improve the above structure, the structure is as follows:

[0028] Such as figure 1 , figure 2 with image 3 Shown, a kind of cutter placement frame comprises frame 1, and the bottom of frame 1 is provided with pulley 2, and frame 1 is provided with several placement grooves 3, and placement groove 3 is provided with cutter placement box 4, and described placement box 4 The outside is provided with an adapter 10 docked with the placement slot 3, and the adapter 10 is provided with a conduction device 11 for external power supply. The placement slot 3 is provided with a socket for receiving the adapter 10, and the placement slot 3 outside A socket 12 for connecting the power supply is provided, and a switch is provided on the socket 12; the cutter placement box 4 includes a cutter board 12 and a box body, and the cutter board 13 is covered on the box body by a slot, and the cutter board 13 is provided with A number of accommodation cavities 5, a sponge pad...

Embodiment 3

[0031] To further improve the above structure, the structure is as follows:

[0032] Such as figure 1 , figure 2 with image 3 Shown, a kind of cutter placement frame comprises frame 1, and the bottom of frame 1 is provided with pulley 2, and frame 1 is provided with several placement grooves 3, and placement groove 3 is provided with cutter placement box 4, and described placement box 4 The outside is provided with an adapter 10 docked with the placement slot 3, and the adapter 10 is provided with a conduction device 11 for external power supply. The placement slot 3 is provided with a socket for receiving the adapter 10, and the placement slot 3 outside A socket 12 for connecting the power supply is provided, and a switch is provided on the socket 12; the cutter placement box 4 includes a cutter board 12 and a box body, and the cutter board 13 is covered on the box body by a slot, and the cutter board 13 is provided with A number of accommodation cavities 5, a sponge pad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com