Knife sharpener

A knife sharpener and linkage rod technology, used in grinding/polishing equipment, grinding/polishing hand tools, metal processing equipment, etc., can solve the problem of occupying storage space, difficult to improve production efficiency, and single function of the sharpener question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

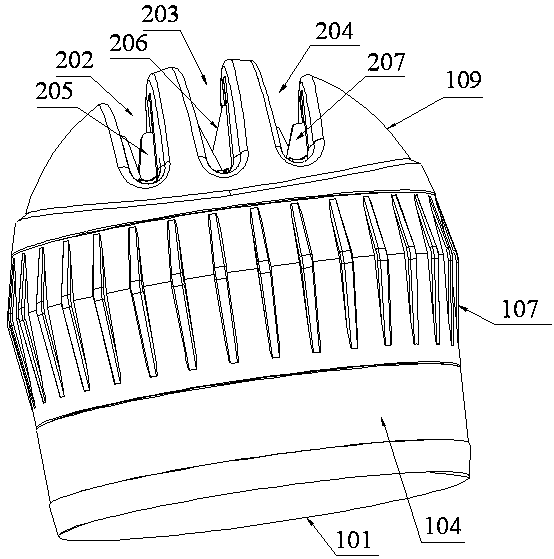

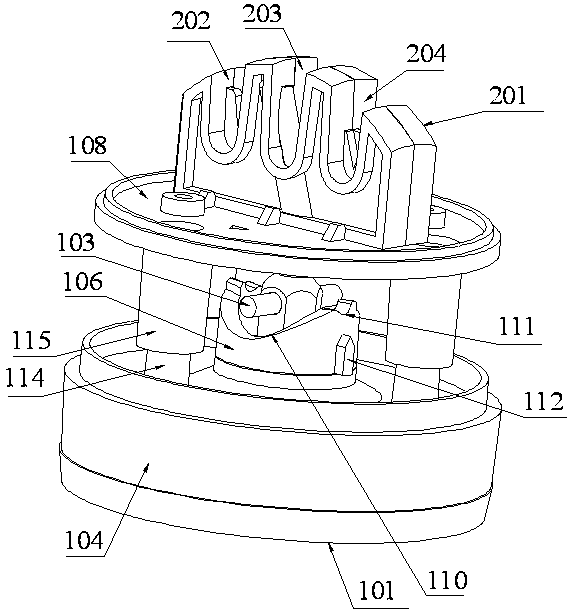

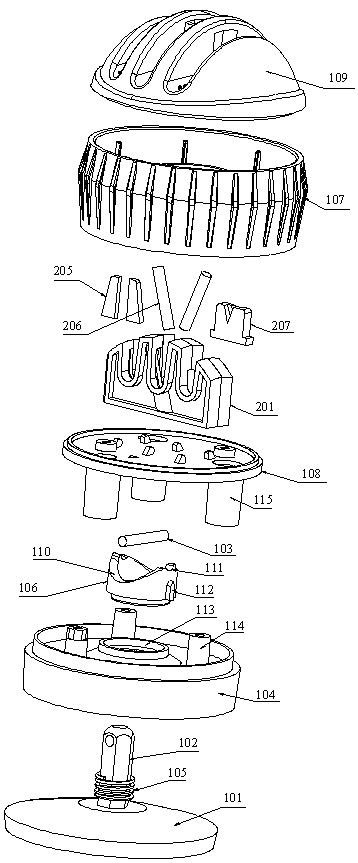

[0019] refer to Figure 1 to Figure 5 , an embodiment of a knife sharpener of the present invention is proposed, which includes a vacuum suction cup with a linkage rod 102 that can be adsorbed on a plane, fixed on the linkage rod 102 and can drive the linkage rod 102 to move longitudinally The linkage pin 103, the base 104 sleeved outside the linkage rod 102 and positioned above the vacuum chuck, and the base 104 sleeved outside the linkage rod 102 and clamped between the base 104 and the vacuum chuck play a reset role on the vacuum chuck The return spring 105, the rotating seat 106 that is arranged on the base 104 and is sleeved outside the linkage rod 102 and can drive the linkage pin 103 to move longitudinally, the turntable 107 that is installed on the top of the base 104 and is linked with the rotating seat 106, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com