Control method for preventing deviation of band steel in first-pass rolling procedures

A technology of rolling process and control method, applied in the direction of rolling force/roll gap control, etc., can solve the problems of reducing the ability of strip steel to resist lateral disturbance, reducing the stability of high-speed rolling process, etc., so as to reduce the occurrence of deviation and breakage. The probability of avoiding the increase of roller consumption and improving the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

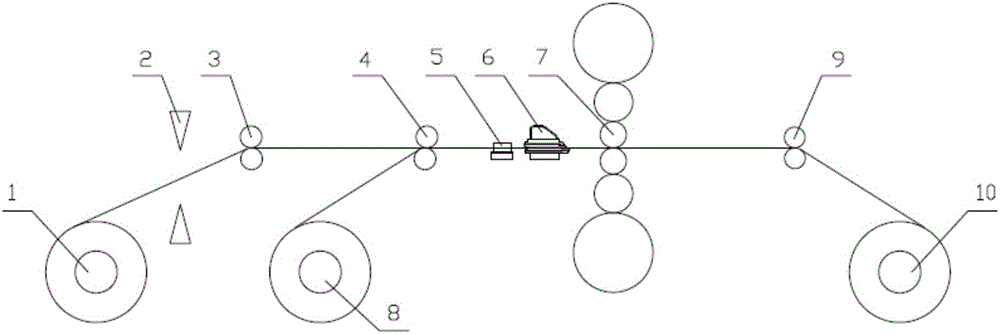

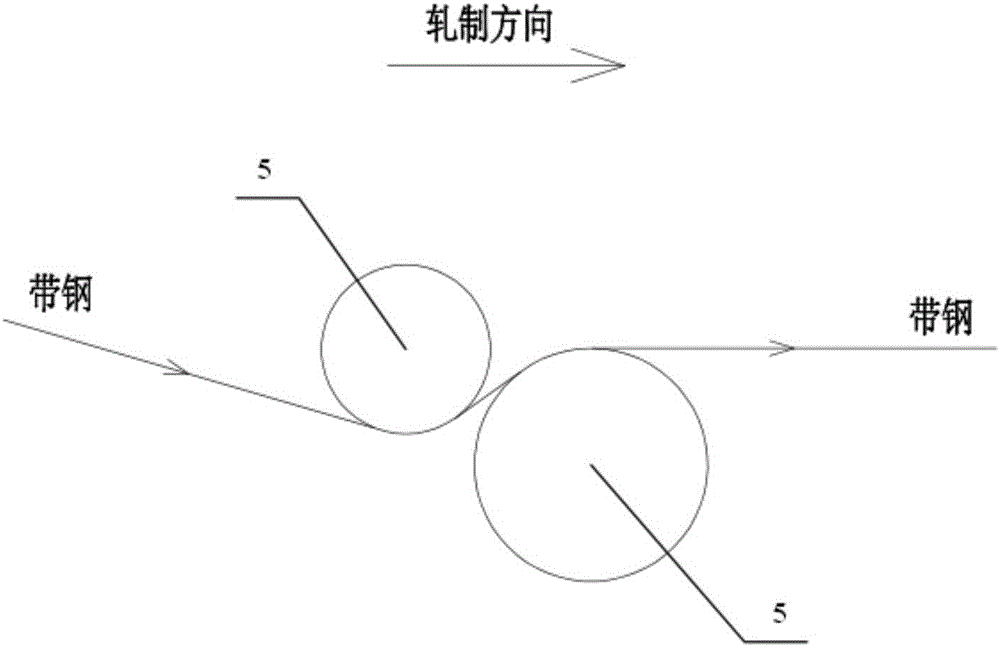

[0021] Such as figure 1 with figure 2 As shown, the present invention provides a kind of control method that prevents strip from running off in the first pass rolling process, comprising the following steps:

[0022] S1. After the strip is coiled by the uncoiler 1, the CPC device 2 is put into alignment during the strip threading process, wherein, during the first rolling process, the strip is on the reversible cold rolling mill with small roll diameter and single stand The uncoiling tension is 20% to 45% greater than the coiling tension in the pickling unit;

[0023] S2. The strip passes through the uncoiling pinch roller 3 and the entrance steering pinch roller 4 to keep the strip threaded stably during the strip t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com