Novel partial fourteen-roller steel plate cold rolling mill structure

A technology of cold rolling mill and steel plate, applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc., can solve the problem of unreasonable force distribution, unreasonable layout of force system, and inability to control and adjust the rolling board and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

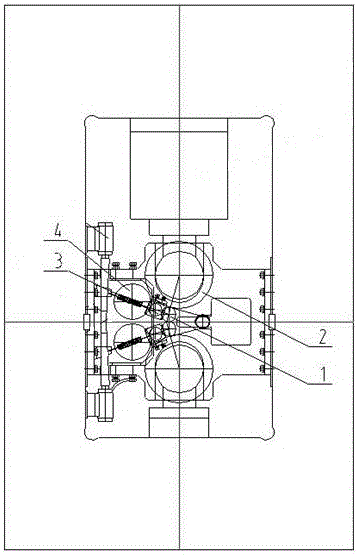

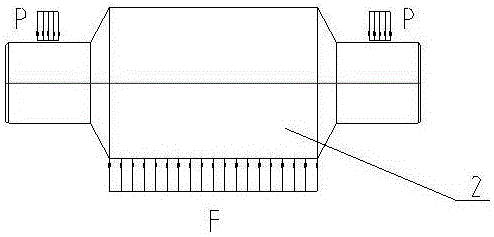

[0027] as attached figure 1 As shown, the existing eight-high steel plate cold rolling mill is transformed on the basis of the traditional four-high rolling mill. The work roll is deviated from the center line of the roll by a distance, and a transition support roll 3 and a backing bearing roll 4 are added. and support roll 2 to ensure the rigidity of the work roll 1. The steel plate shape adjustment of the partial eight-roll steel plate cold rolling mill relies on the upward pressure of the oil cylinder and the pressure on the top plate through the wedge. The pressure acts on the shaft of the backing bearing and It produces local bending to increase the longitudinal rigidity of the rolling mill when the bending part is rolled, so as to locally increase the deformation of the rolled steel plate and achieve the purpose of adjusting the shape of the plate. But its adjustment effect is not obvious, and the force acting on the backing bearing is very large when the plate shape is ...

Embodiment 2

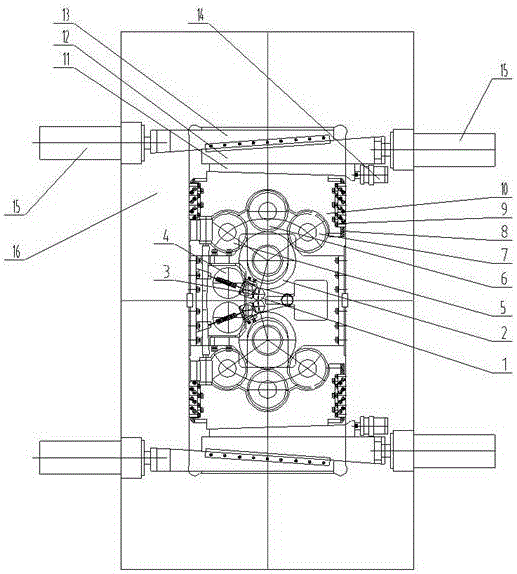

[0033] On the basis of Embodiment 1, the described depressing device includes an upper wedge 13, a lower wedge 12 and an adjustable support block 10 arranged in sequence from far to near, and the tail end of the upper wedge 13 and the lower wedge 12 Oil cylinders 15 are respectively connected, and the oblique wedge angles of the upper wedge 13 and the lower wedge 12 are the same, and the thinner tips of the upper wedge 13 and the lower wedge 12 are arranged in opposite directions. Sliding fit with the opposite surface of the lower wedge 12, the adjustable support block 10 is provided with several, and several adjustable support blocks 10 are evenly arranged under the lower wedge 12, the adjustable support block 10 adopted in the present invention It is an existing product, and will not be described in detail. The contact surface between the adjustable support block 10 described in this embodiment and the backing bearing roll below it is a semicircular arc surface, and the semic...

Embodiment 3

[0036] On the basis of Embodiment 2, several wedges 11 are arranged between the lower wedge 12 and the several adjustable support blocks 10, and several oil cylinders 14 are correspondingly connected to the several wedges 11 respectively. When it is necessary to adjust the plate shape at a certain point, one of the oil cylinders 14 corresponding to the adjustment point enters the pressure oil, and pushes the wedge 11 at the corresponding point of the oil cylinder to move downward, and the wedge 11 bears against the corresponding The adjustable support block 10 at the point is pressed down, and when the adjustable support block 10 moves downward, the shaft and the backing bearing pressing the corresponding point move down, so that the shaft of the backing bearing is slightly bent at this point to increase The longitudinal rigidity of the roller system at this point can complete the adjustment of the plate shape reduction in the transverse direction of the rolled steel plate surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com