Bismuth tungstate nanometer photocatalyst and method for preparing same

A nano-photocatalyst, bismuth tungstate technology, applied in the field of photocatalysis, can solve the problems of limited production efficiency, time-consuming, cumbersome steps, etc., and achieve the effects of short time-consuming, shortened reaction time, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The invention provides a preparation method of bismuth tungstate nano photocatalyst, comprising the following steps:

[0034] a) dissolving the bismuth source in acid to form a transparent solution;

[0035] b) dissolving the tungsten source in water with or without certain additives to form a transparent solution;

[0036] c) mixing the solution obtained in step a and step b with critical water in a certain very short time to obtain a product-containing suspension;

[0037] d) The resulting suspension then enters the cooling circuit and is collected;

[0038] e) performing solid-liquid separation on the collected suspension, washing and drying the solid to obtain the final bismuth tungstate nano photocatalyst.

[0039] In the invention, firstly, the bismuth source is dissolved in a certain concentration of dilute acid to obtain a transparent solution containing bismuth ions. In the present invention, the bismuth source is any acid-soluble bismuth salt, preferably bi...

Embodiment 1

[0049] Dissolve 40mmol of bismuth nitrate in 400ml of 0.4mol / L dilute nitric acid to obtain a bismuth source solution; dissolve 20mmol of sodium tungstate in 400ml of water to obtain a tungsten source solution; simultaneously extract bismuth source solution, tungsten source solution, and deionized water at 350°C and 22Mpa into the reactor, and the pressure is controlled at about 22Mpa for the reaction, the extraction flow rates are 5ml / min, 5ml / min and 20ml / min respectively, and the suspension is obtained after 7 to 8 seconds of reaction. Turbid liquid; the suspension enters the cooling pipeline and is collected after cooling, and the obtained suspension is subjected to 6000r / min high-speed centrifugation to obtain a solid, and the obtained solid is washed with deionization until the surface of the catalyst is neutral, and the solid is placed in a vacuum freeze dryer Medium dry.

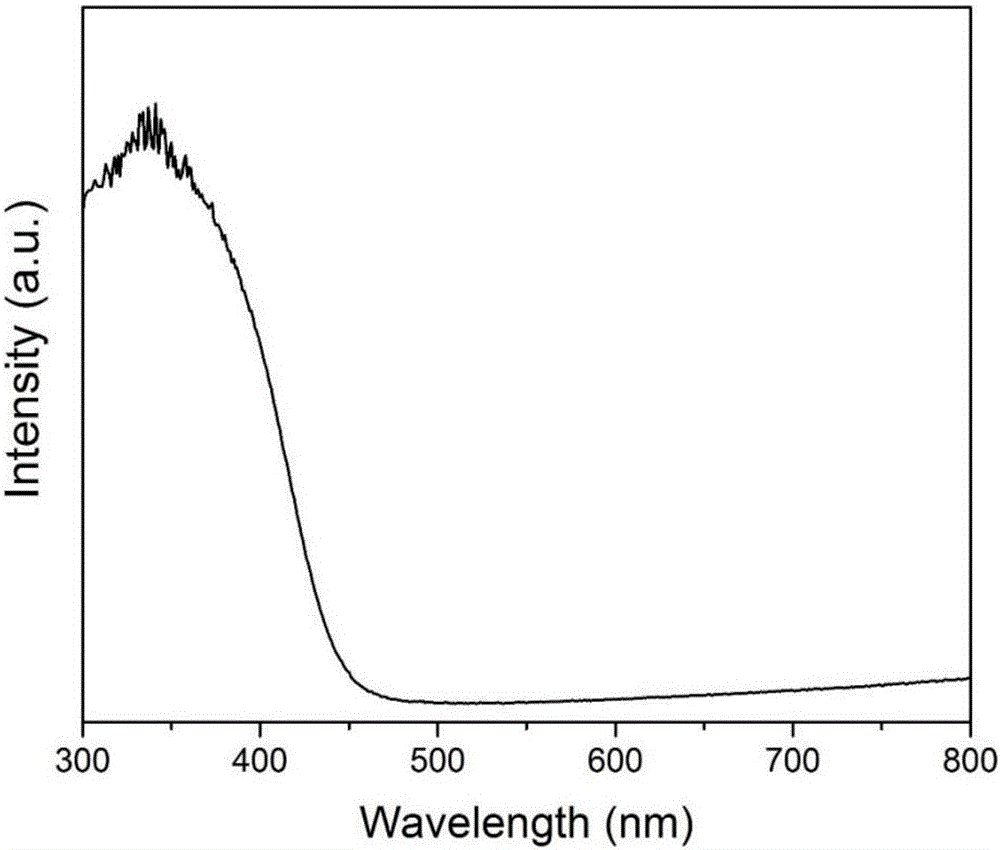

[0050] The XRD spectrum of the obtained bismuth tungstate is completely consistent with the spect...

Embodiment 2

[0055] Dissolve 40mmol of bismuth nitrate in 400ml of 0.6mol / L dilute nitric acid to obtain a bismuth source solution; dissolve 20mmol of potassium tungstate in 400ml of water to obtain a tungsten source solution; simultaneously extract bismuth source solution, tungsten source solution, and deionized water at 400°C and 22Mpa into the reactor, and the pressure is controlled at about 22Mpa for the reaction, the extraction flow rates are 5ml / min, 5ml / min and 25ml / min, and the suspension is obtained after 6 to 7 seconds of reaction. Turbid liquid; the suspension enters the cooling pipeline and is collected after cooling, and the obtained suspension is subjected to 6000r / min high-speed centrifugation to obtain a solid, and the obtained solid is washed with deionization until the surface of the catalyst is neutral, and the solid is placed in a vacuum freeze dryer Medium dry.

[0056] The XRD spectrum of the obtained bismuth tungstate and JCPDS39#0256Bi 2 WO 6 Completely consistent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com