Functional magnetic carbon material and preparation method and application thereof

A magnetic carbon and functionalization technology, applied in chemical instruments and methods, inorganic chemistry, other chemical processes, etc., to achieve the effect of high modification content, simple synthesis process and low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

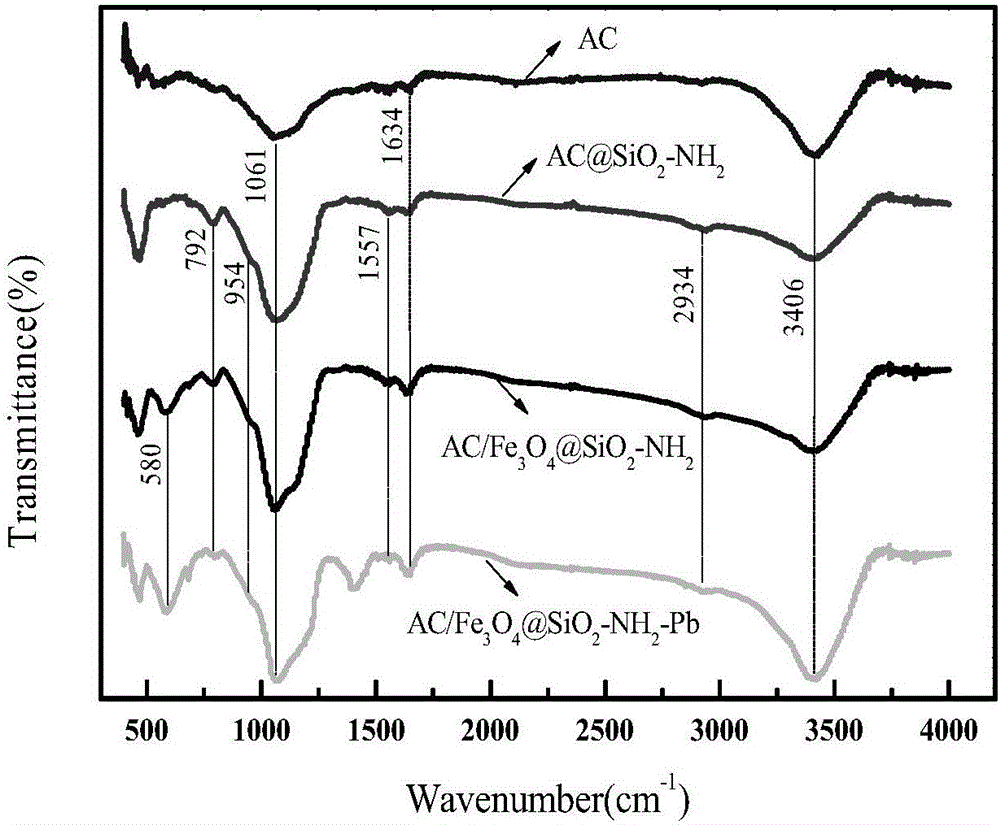

[0028] Embodiment 1: Amino functionalized magnetic activated carbon (mAC:mFe 3 o 4=1:0.25) Preparation of composite material

[0029] (1) Magnetic activated carbon (AC / Fe 3 o 4 ) preparation

[0030] 0.5883gFeCl 3 ·6H 2 O and 0.3779g FeSO 4 ·7H 2 O was dissolved in 25 mL deionized water and ultrasonically dissolved, where Fe 3+ with Fe 2+ The molar ratio of the concentration is 1.6:1, then add 25mL polyethylene glycol solution and 0.5g activated carbon ultrasonic dispersion, then at a flow rate of 200mL / minN 2 Under the protection of the environment, add dropwise the mixed solution of 10mL ammonia water and 25mL polyethylene glycol, stir and react in a water bath at a stirring speed of 400r / min and a temperature of 60°C for 1h, stop stirring and keep the temperature for 1h, and then wash with deionized water To neutral, the mass ratio mAC:mFe is obtained after magnetic separation 3 o 4 =1:0.25 magnetic activated carbon.

[0031] (2) Amino functionalized magnetic a...

Embodiment 2

[0033] Embodiment 2: Amino functionalized magnetic activated carbon (mAC:mFe 3 o 4 =1:0.5) Preparation of composite material

[0034] (1) The preparation of the magnetic activated carbon carrier is as described in step (1) in Example 1. The difference is that the added FeCl 3 ·6H 2 O and FeSO 4 ·7H 2 The masses of O are 1.1767g and 0.7558g, respectively.

[0035] (2) Amino functionalized magnetic activated carbon (mAC:mFe 3 o 4 =1:0.5) is prepared as described in step (2) in Example 1.

Embodiment 3

[0036] Embodiment 3: Amino functionalized magnetic activated carbon (mAC:mFe 3 o 4 =1:0.15) Preparation of composite material

[0037] (1) The preparation of the magnetic activated carbon carrier is as described in step (1) in Example 1. The difference is that the added FeCl 3 ·6H 2 O and FeSO 4 ·7H 2 The masses of O are 0.353g and 0.2267g, respectively.

[0038] (2) Amino functionalized magnetic activated carbon (mAC:mFe 3 o 4 =1:0.15) is prepared as described in step (2) in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com