Ultralow emission method and device for split-type flue gas desulfurization and dust removal

A technology for desulfurization, dust removal, and discharge devices, which is applied in separation methods, chemical instruments and methods, and gas treatment, and can solve problems such as increasing tower height, high energy consumption, and high operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

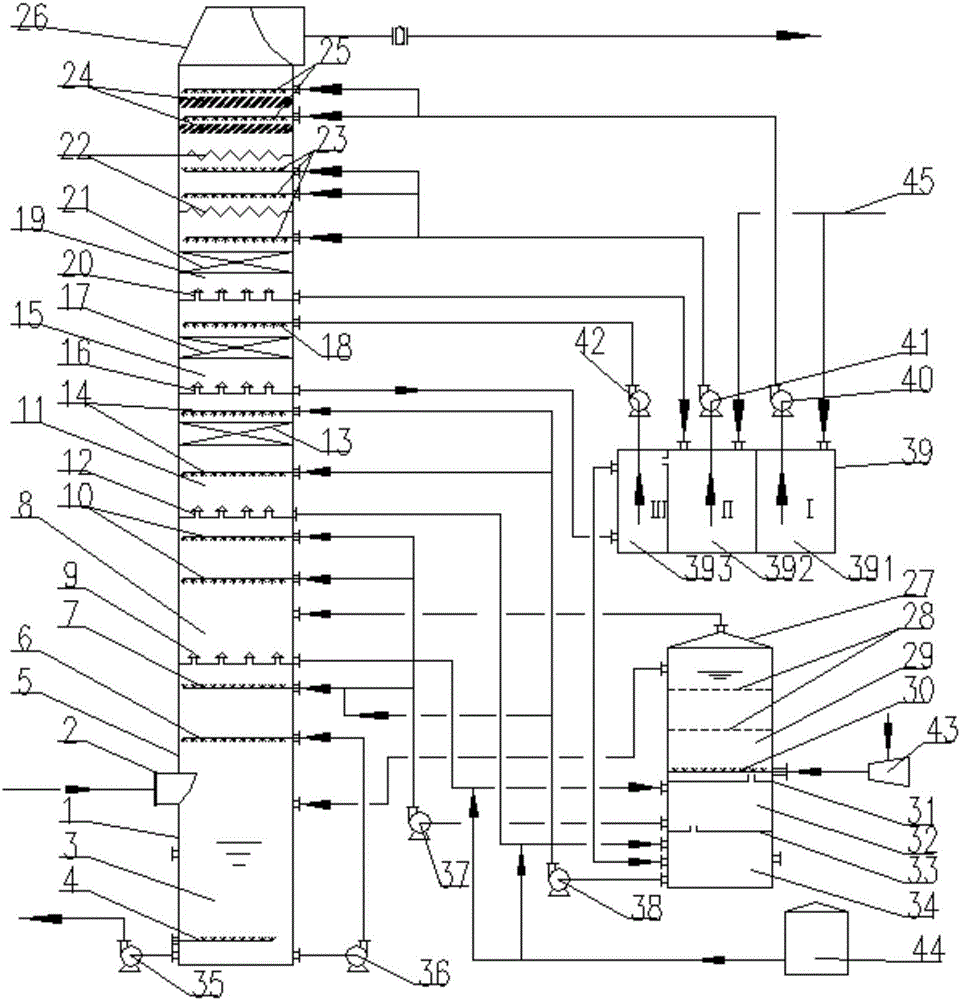

[0021] Such as figure 1 As shown, a separate ultra-low emission device for flue gas desulfurization and dust removal includes a desulfurization tower 1 and an oxidation circulation tank 27 placed outside the desulfurization tower 1; the desulfurization tower 1 and the oxidation circulation tank 27 are connected by pipelines. Compared with the existing device, the external oxidation circulation tank 27 can reduce the height of the desulfurization tower, and the oxidation circulation tank 27 is selected according to the flue gas conditions, which is more reasonable in type selection, can reduce energy consumption and investment.

[0022] Among them, the flue gas inlet 2 and the flue gas outlet 26 of the desulfurization tower are provided on the tower body of the desulfurization tower 1, and the flue gas inlet 2 and the flue gas outlet 26 of the desulfurization tower are arranged in sequence in the desulfurization tower 1 according to the flow direction of the flue gas. Washing a...

Embodiment 2

[0039] A split-type ultra-low emission method for flue gas desulfurization and dust removal. The device described in Example 1 is used for desulfurization and dust removal. Hot flue gas enters the washing and cooling section 5 from the flue gas inlet 2, and is sprayed countercurrently with ammonium sulfate solution. The hot flue gas is cooled by adiabatic evaporation during this process. The heat of the flue gas evaporates part of the water in the solution, concentrates it to saturation, and precipitates ammonium sulfate grains. The content of the crystal slurry reaches the process control index and is transported out of the tower;

[0040] When the flue gas enters the primary absorption section 8, the absorption liquid with a density of 1.15kg / L and a pH value of 6 is used for spraying to mainly remove SO 2 , removal rate > 90%; the absorption liquid used in the primary absorption section is a solution containing ammonium sulfite and ammonium sulfate, and the molar ratio of a...

Embodiment 3

[0045] A split-type ultra-low emission method for flue gas desulfurization and dust removal. The device described in Example 1 is used for desulfurization and dust removal. Hot flue gas enters the washing and cooling section 5 from the flue gas inlet 2, and is sprayed countercurrently with ammonium sulfate solution. The hot flue gas is cooled by adiabatic evaporation during this process. The heat of the flue gas evaporates part of the water in the solution, concentrates it to saturation, and precipitates ammonium sulfate grains. The content of the crystal slurry reaches the process control index and is transported out of the tower;

[0046] When the flue gas enters the primary absorption section 8, ammonium sulfate solution with a density of 1.1kg / L and a pH value of 5.8 is used as the absorption liquid for spraying, mainly to remove SO 2 , The removal rate is >90%; the absorption liquid used in the primary absorption section is a solution containing ammonium sulfite and ammon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com