Functional dyed spectacle lens

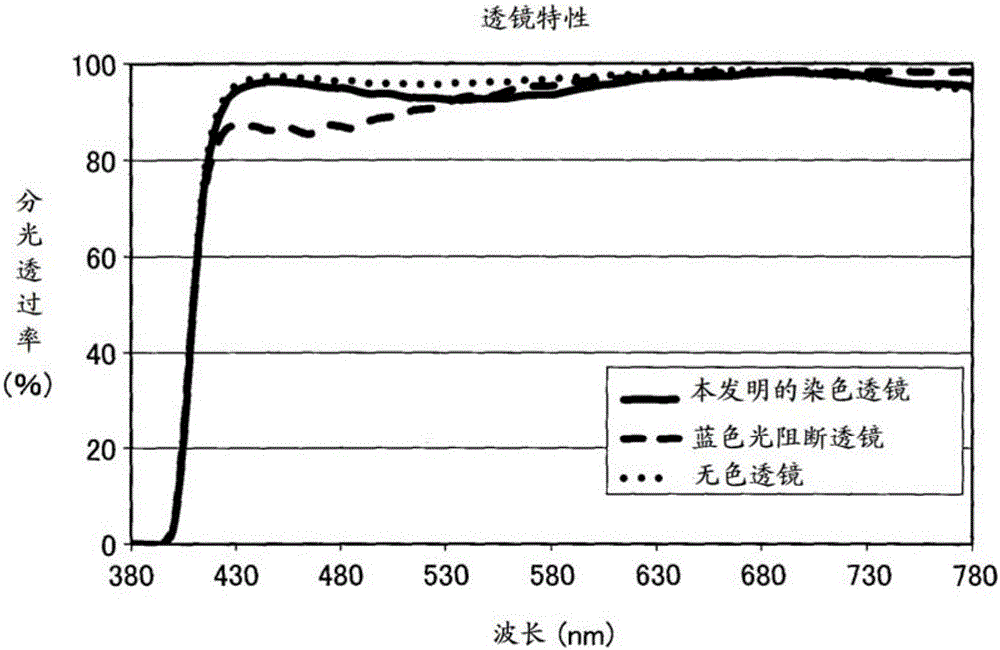

A spectacle lens, functional technology, applied in the direction of glasses/protective glasses, glasses/goggles, instruments, etc., can solve the problems of large reduction of visual transmittance and reduced transmittance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0129] (adjustment of staining solution)

[0130] First, a dyeing liquid is adjusted as follows with a dye, a surfactant, and pure water.

[0131] Put 1000 parts by weight of pure water into a container, add 2.0 parts by weight of Kayaron Polyester Yellow AL dye (manufactured by Nippon Kayaku Co., Ltd.) parts to make staining solution 1. In addition, put 1000 parts by weight of pure water into a container, add 2.0 parts by weight of Kayalon Polyester Blue AUL-S dye (manufactured by Nippon Kayaku Co., Ltd.) as a blue dye, and 1.0 parts by weight of NikkaSanSal#7000 to prepare a dyeing solution 2. Separately, 1000 parts by weight of pure water was put into a container, and 2.0 parts by weight of Kayalon Polyesterred AUL-S dye and 1.0 part by weight of NikkaSanSal#70000 were added as a red dye to prepare dyeing solution 3 .

[0132] (Dyeing of plastic lenses and production of dyed lenses)

[0133] Next, the prepared three staining solutions 1, 2 and 3 were heated to 90°C resp...

Embodiment 2

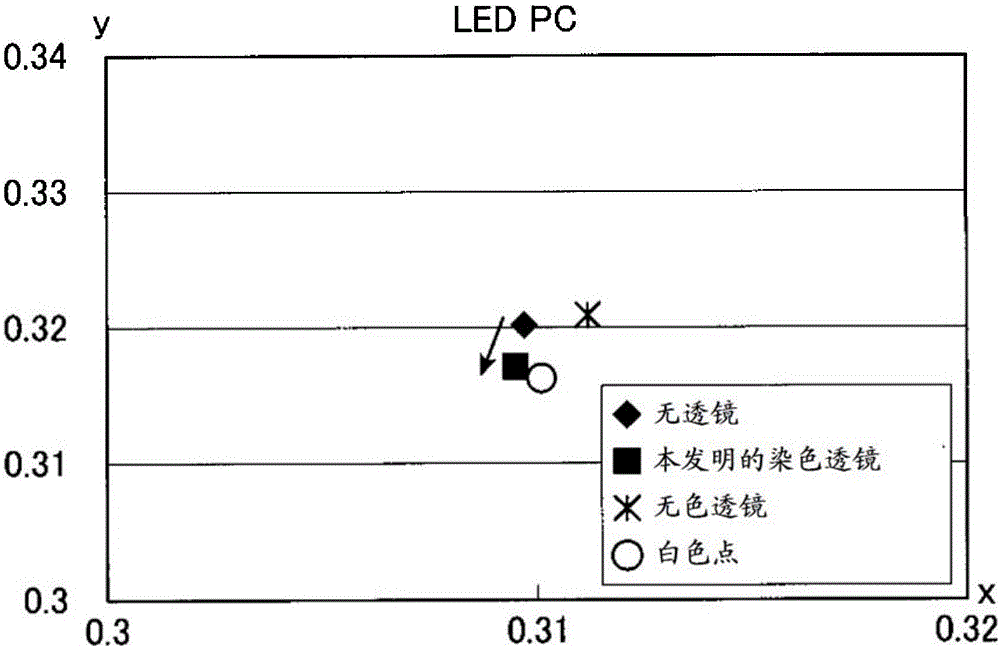

[0146] A plastic lens (Niconlight 4AS) having a refractive index of 1.67 was immersed in the same three dyeing solutions 1, 2, and 3 as in Example 1. In the same manner as in Example 1, a hard coat film and an antireflection film were applied to the obtained dyed lens to obtain the intended dyed lens. This plastic dyed lens was attached to a spectacle frame, and the same wearing test as in Example 1 was carried out by subjects aged about 40 to 60, and sensory evaluation was performed. In addition, the spectral characteristics of the plastic dyed lens were measured.

[0147] In the sensory evaluation results of the wearing test of this plastic dyed lens, the same evaluation as in Example 1 was obtained.

[0148] In addition, the dyeing density of this plastic lens was 3.6%.

[0149] These results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com