Inspection system, inspection method, and readable recording medium

An inspection system and sampling inspection technology, applied in the direction of optical testing flaws/defects, instruments, measuring devices, etc., can solve the problems of discrete differences in the characteristic values of inspection blocks, and achieve the effect of stable grade division and good production quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

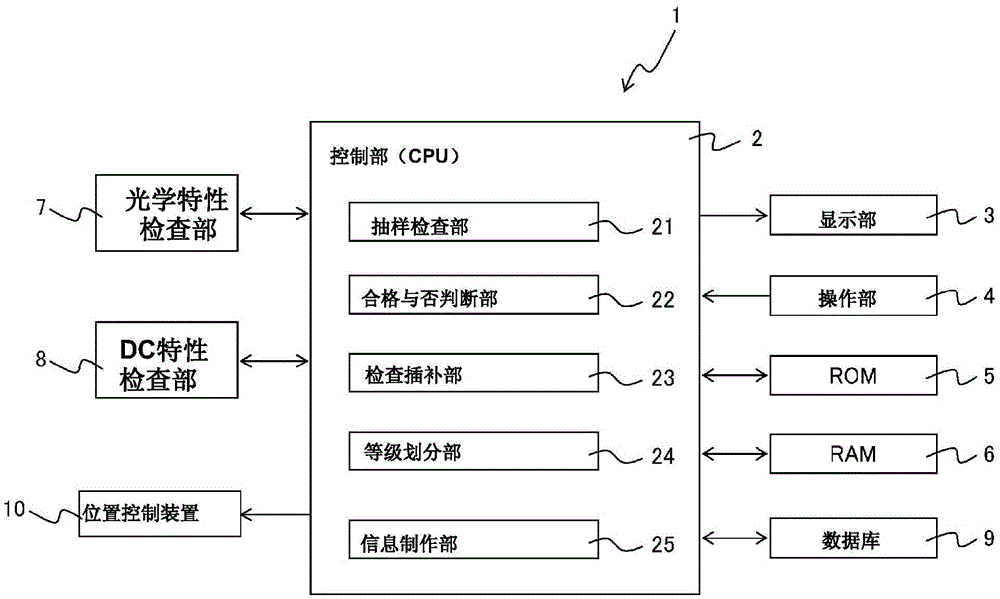

[0086] figure 1 It is a block diagram showing an example of the main part hardware configuration of the inspection system according to Embodiment 1 of the present invention.

[0087] exist figure 1 Among them, the inspection system 1 of the first embodiment is composed of a computer system, including: a CPU2 (central processing unit) as a control unit for overall control; an initial screen, a selected scene, and a control result screen of the CPU2 are displayed on the display screen. and the display unit 3 of the operation input screen, etc.; the keyboard, mouse, and touch panel for inputting instructions to the CPU 2, and the operation unit 4 of an input device such as receiving an input via a communication network (such as the Internet, an intranet); ROM5 of a computer-readable recording medium for programs and its data, etc.; reads the control program and its data, etc. at startup, reads and stores data in each control performed by the CPU2, and operates as a work memory...

Embodiment approach 2

[0180] For the above Embodiment 1 Figure 5 (b) and Figure 5 The flow example in (c) described the case where the sampling inspection of optical characteristics and the entire inspection of DC characteristics are performed using different flows. However, in the second embodiment, as Figure 5 (d) and Figure 5 As in the flow example of (e), a case will be described in which inspection (OPT+DC) is performed by integrating the single-unit measurement of optical characteristics and multiple simultaneous measurement functions of DC characteristics in one device. In addition, in this Embodiment 2, except Figure 5 (d) and Figure 5 Other than the flow example of (e), other content such as (number of interpolation data; number of sampling chips), (example of pre-evaluation of the introduction of the number of sampling chips), (judgment criteria for pre-evaluation of the introduction of the number of sampling chips; interpolation inspection evaluation Judgment criteria), (interp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com