The method and its mechanism of taking material and testing the integrated structure and the silicon wheat sorting machine

A technology of testing mechanism and retrieving mechanism, which is applied in the direction of sorting, sequence/logic controller program control, electrical program control, etc., can solve the problems of low work efficiency, low production capacity, cumbersome installation, etc., and improve production Efficiency, accurate classification, and the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

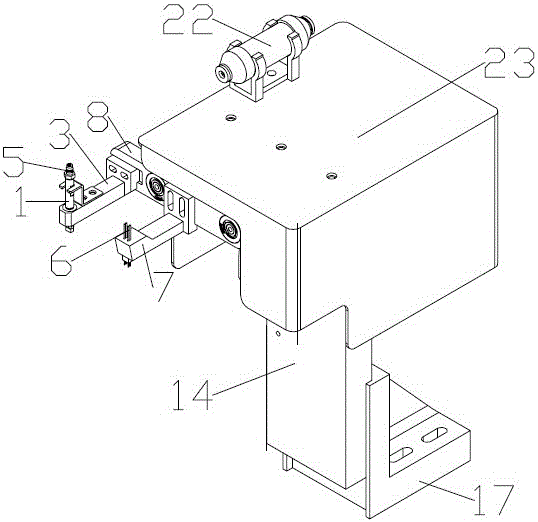

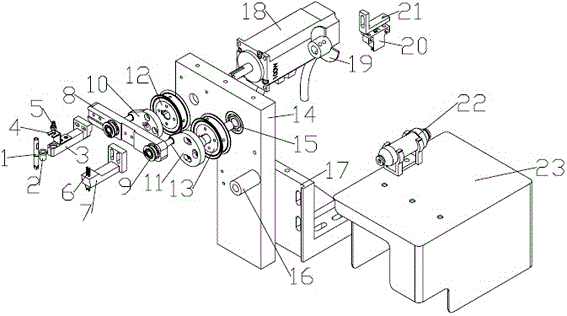

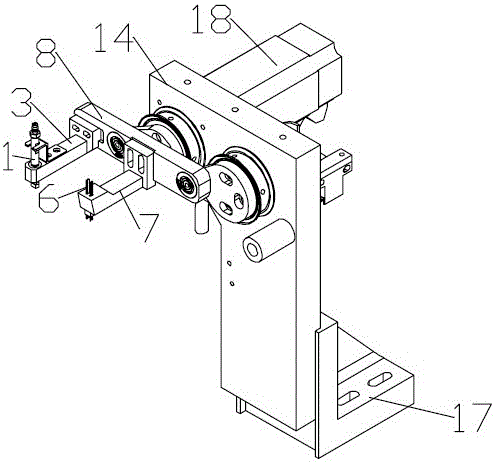

[0038] The method for the integrated structure of the retrieving mechanism and the earpiece testing mechanism of the automatic silicon wheat sorting machine of the present invention is characterized in that: the integrated structure of the reclaiming mechanism and the earphone testing mechanism includes a retrieving nozzle, a testing probe Needle, motor, pull rod, main eccentric wheel, auxiliary eccentric wheel, reclaiming arm and probe arm, the reclaiming suction nozzle is fixed on the pull rod through the reclaiming arm, the retrieving nozzle is always perpendicular to the pull rod, the main eccentric wheel and auxiliary eccentric The wheels are equipped with eccentric shafts, and the test probes are fixed on the pull rods through the probe arms.

[0039] 1) The main eccentric wheel and the auxiliary eccentric wheel are driven by the motor to rotate, the pull rod always moves in parallel under the drive of the main eccentric wheel and the auxiliary eccentric wheel, and the fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com