A kind of LED epitaxial structure and growth method thereof

A technology of epitaxial structure and growth method, which is applied in the field of LED epitaxial structure and its growth, can solve problems such as failing to meet brightness requirements, and achieve the effect of improving light efficiency, improving light efficiency, and simplifying process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

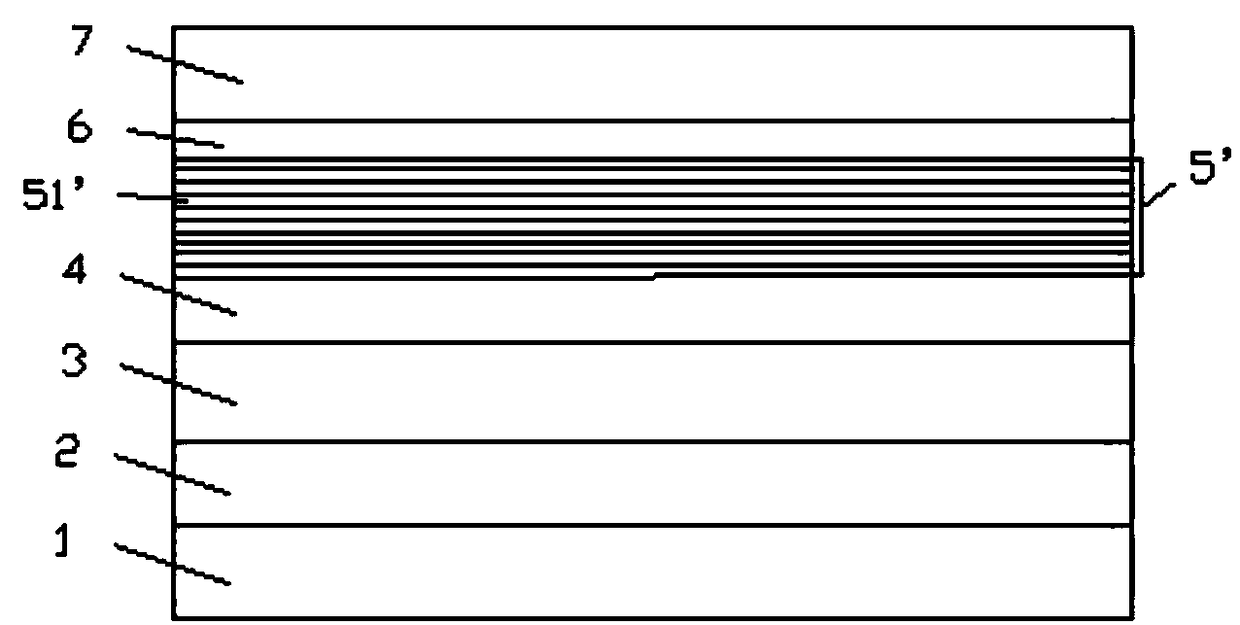

[0057] see Figure 4 as well as Figure 5 , an LED epitaxial structure, including a sapphire substrate 1, a low-temperature buffer layer 2, a GaN layer 3, a Si-doped N-type GaN layer 4, a light-emitting layer 5, a P-type AlGaN layer 6, and a Mg-doped P type GaN layer 7 .

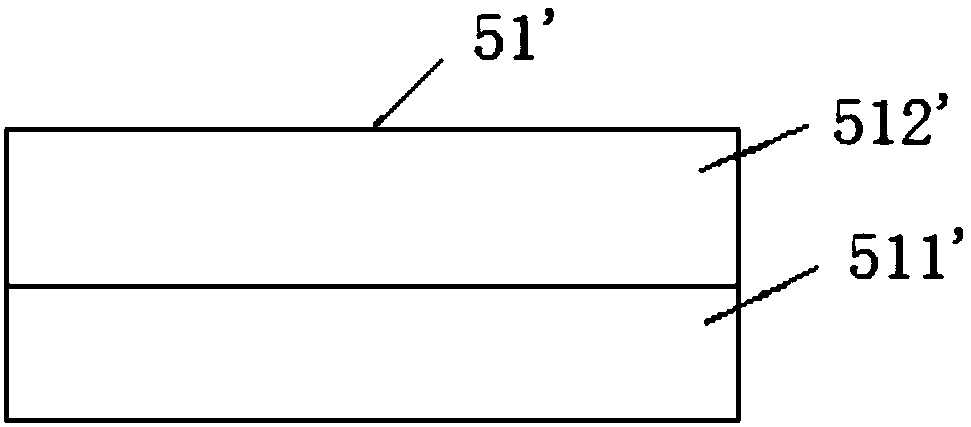

[0058] The light-emitting layer 5 includes 10 light-emitting monolayers 51, and each light-emitting monolayer 51 sequentially includes a low indium composition layer 511, an indium gradient layer 512, a high indium composition layer 513, and a GaN barrier from bottom to top. layer 514, wherein: the content of indium in the low indium composition layer 511 is constant, and its content is 3%; the content of indium in the high indium composition layer 513 is constant, and its content is 20%; From bottom to top, the indium content in the indium gradient layer 512 is gradually changed from the indium content in the low indium composition layer 511 to the indium content in the high indium composition layer 513 ....

Embodiment 2- Embodiment 3

[0077] See Table 1 for the statistics of the parameters of the comparative example and Example 1-Example 3, and the others of Example 2 and Example 3 are the same as Example 1.

[0078] Table 1 comparative example 1 and the partial parameter statistical table of embodiment 1-embodiment 3

[0079]

[0080]

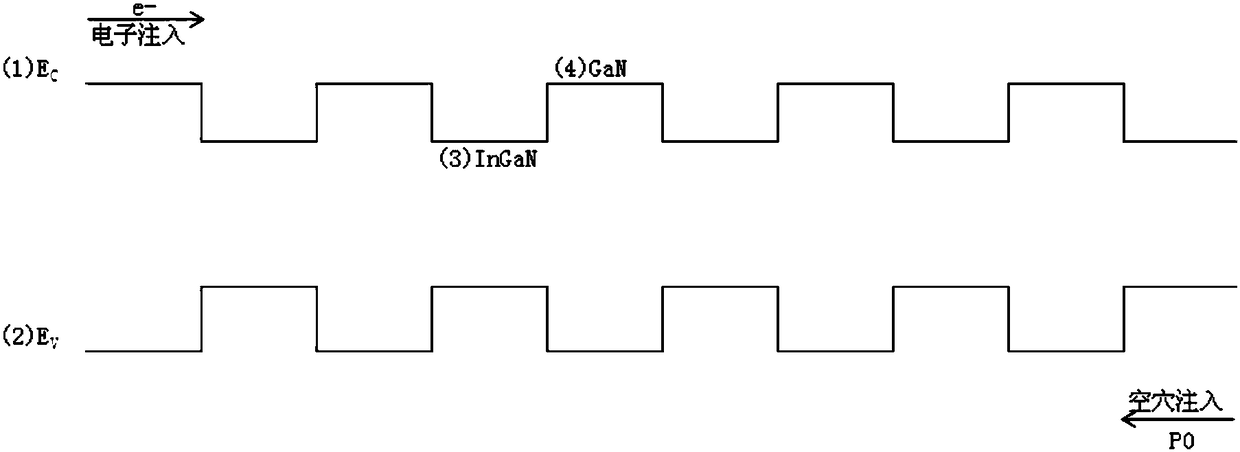

[0081] The energy band diagram of embodiment 2-embodiment 3 is similar to the energy band diagram of embodiment 1.

[0082] The four kinds of LED epitaxial structure products of Comparative Example and Example 1-Example 3 were plated with an ITO layer of about 2300 angstroms under the same pre-process conditions, and plated a Cr / Pt / A μ electrode of about 1500 angstroms under the same conditions, and the same Plating protective layer SiO2 under the condition about 500 angstroms, then under the same condition, the sample is ground and cut into chip particles of 762 μm × 762 μm (30mi × 30mil) to obtain sample 1-4 (comparative example is sample 1, embodiment 1-implementatio...

Embodiment 3- Embodiment 6

[0084] The light-emitting layer 5 in the LED epitaxial structure of Embodiment 3-Example 6 all includes 6 light-emitting monolayers 51 with a period number of 6. The statistics of some parameters of the growth process are shown in Table 2, and the others are the same as in Embodiment 1.

[0085] The energy band diagrams of embodiment 3-embodiment 6 are similar to the energy band diagram of embodiment 1.

[0086] Table 2 Comparative Example 2 and the part parameter statistical table of embodiment 3-embodiment 6

[0087]

[0088]

[0089] Tested in the same manner as in Example 1, the LED epitaxial structures obtained in Example 4, Example 5, and Example 6 were made into LED lamps with brightnesses of 488-490, 491-505, and 504-508, respectively. 2. The LED epitaxial structure is made into an LED lamp with a brightness of 447-449. Therefore, compared with the prior art, the brightness of the present invention is increased by 8.5%-12.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com