Rock seepage-stress coupling shear rheological test box

A rheological test, test box technology, applied in permeability/surface area analysis, measurement device, suspension and porous material analysis, etc., can solve the problem that the shear surface seepage characteristic device has not been reported yet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

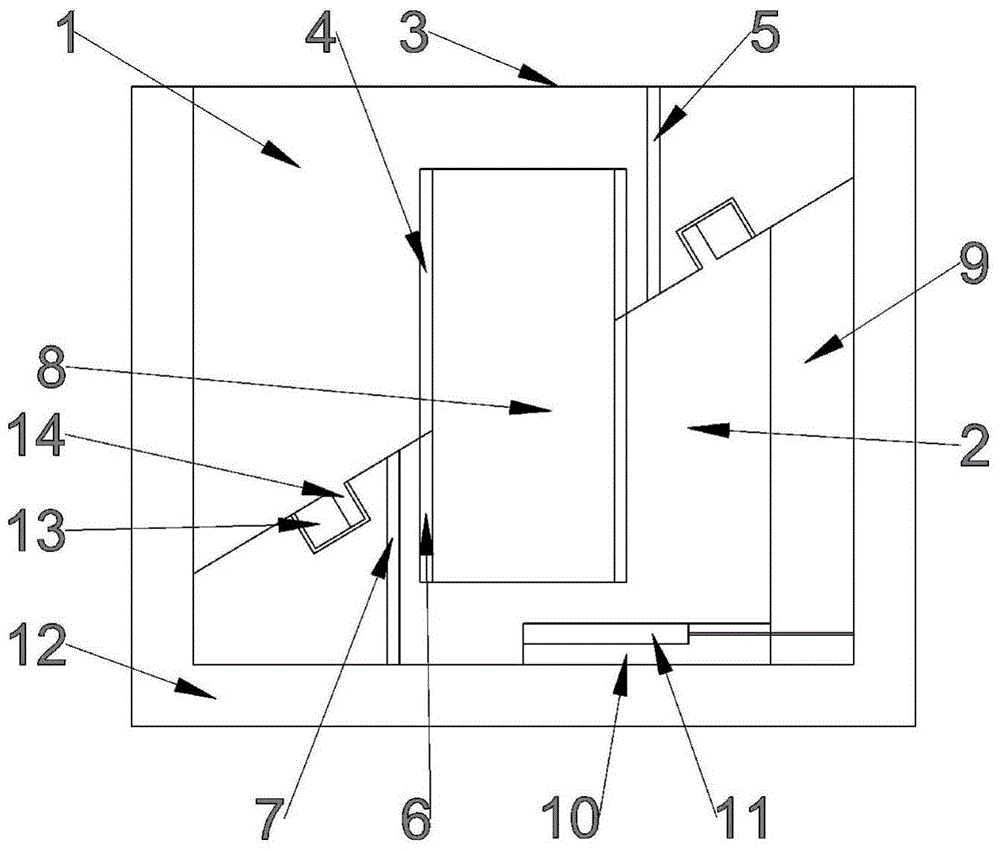

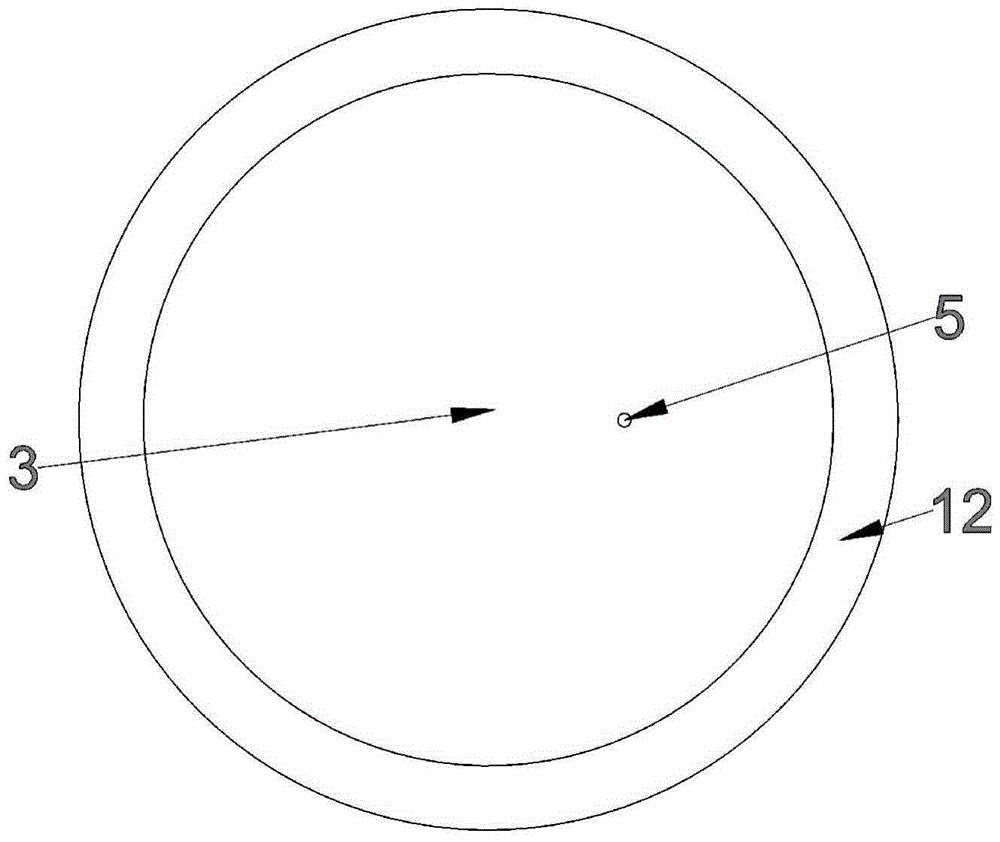

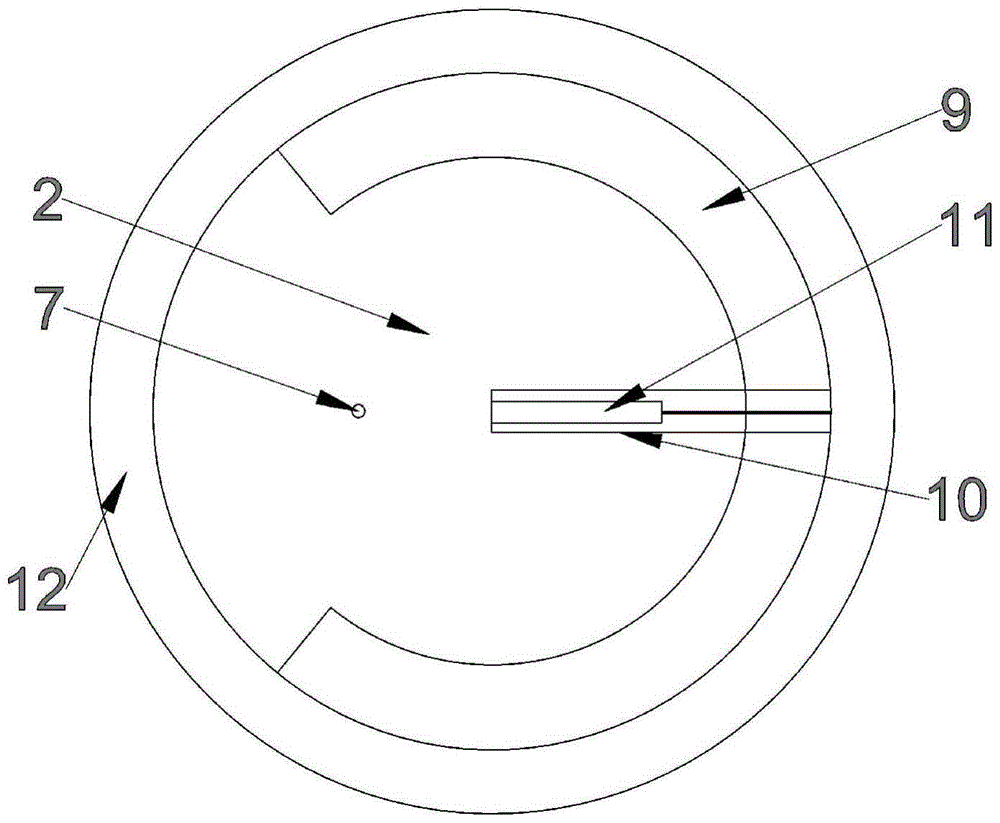

[0019] Example: such as Figure 1~5 As shown, a rock seepage-stress coupled shear rheology test box includes an upper test box 1 and a lower test box 2 placed in a cylindrical sealing sleeve 12, and an inclined plane is used as a contact between the upper and lower test boxes. The surface is combined to form a cylinder, and the contact surface is the shear surface with a certain shear angle α. There are hollow parts inside the upper and lower test boxes, and the hollow parts are covered with high-performance rubber sleeves 4 and 6. The hollow cylindrical tube formed by the combination of the upper and lower test boxes is used for placing the rock sample 8 in it. The rock sample 8 is just cut. section. The upper and lower test boxes 2 are respectively provided with seepage holes 5 and 7 leading from the upper and lower surfaces to the shear plane, and the two seepage holes 5 and 7 are symmetrical along the center of the shear plane. The water seepage holes 5 and 7 are provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com