Fusion device capable of simultaneously treating polymorphic hazardous wastes

A hazardous waste, simultaneous treatment technology, applied in the combustion method, combustion type, incinerator and other directions, can solve the problems of difficult to achieve effective melting, non-toxic emissions, cumbersome operation, low treatment efficiency, etc., to achieve non-toxic treatment, operation Stable and effective, scientific and reasonable treatment methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

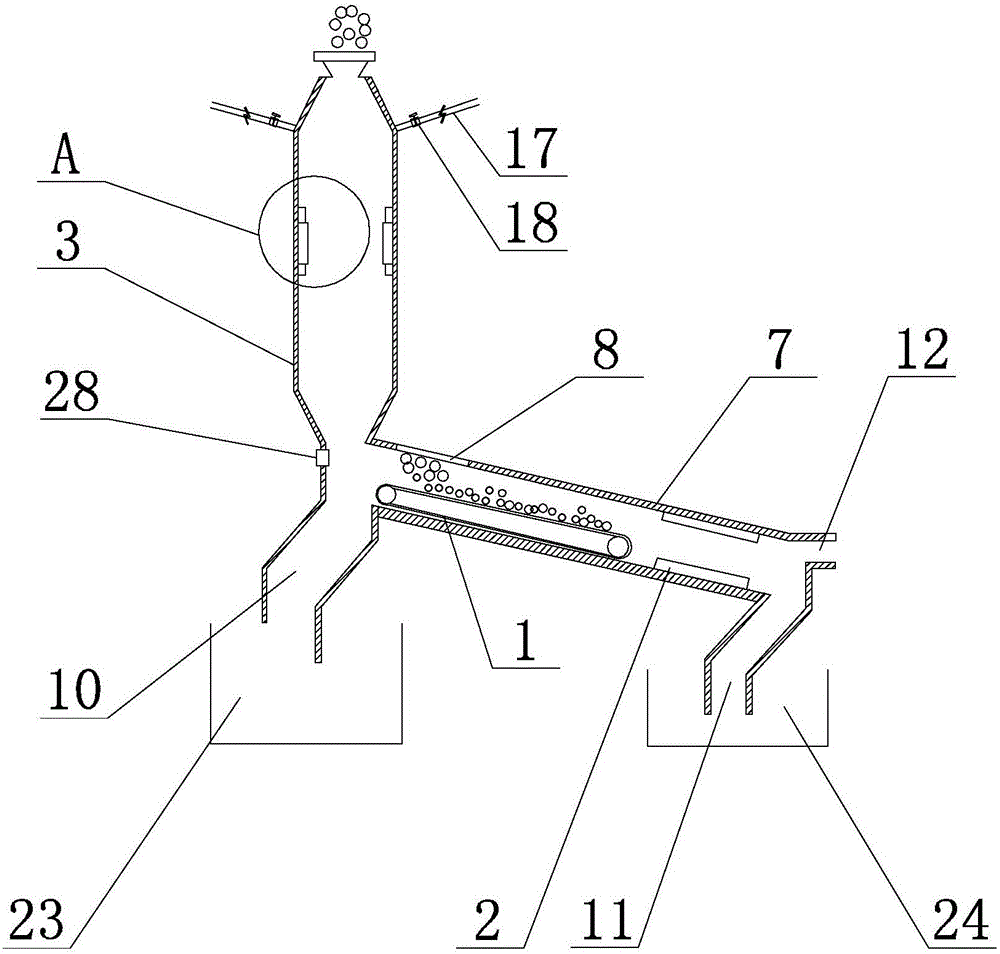

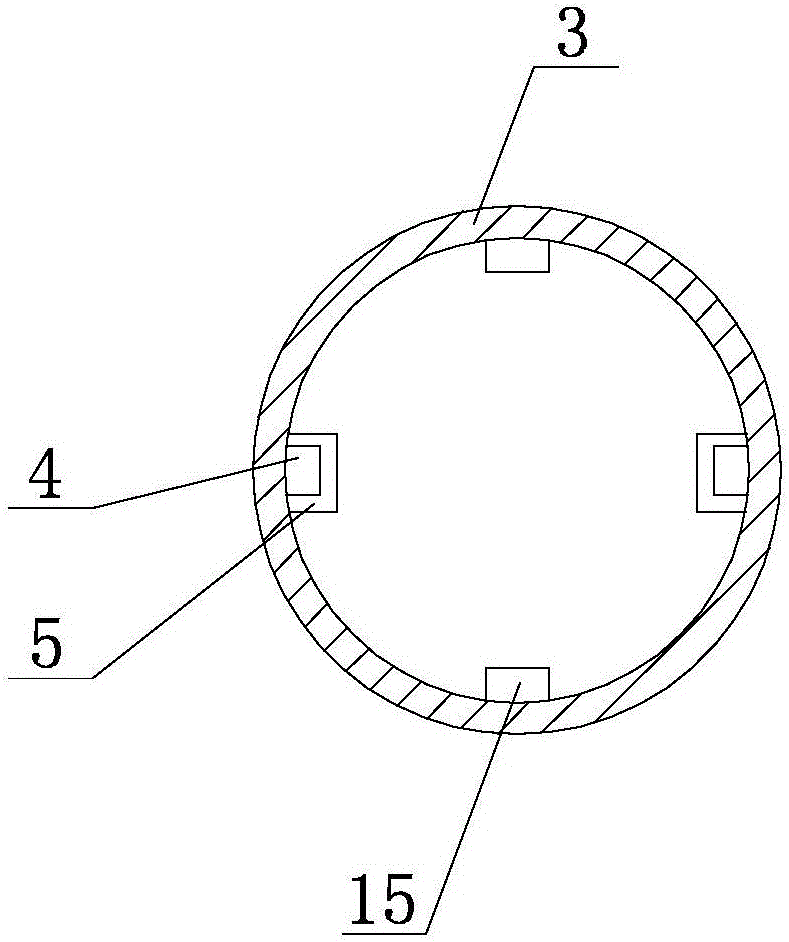

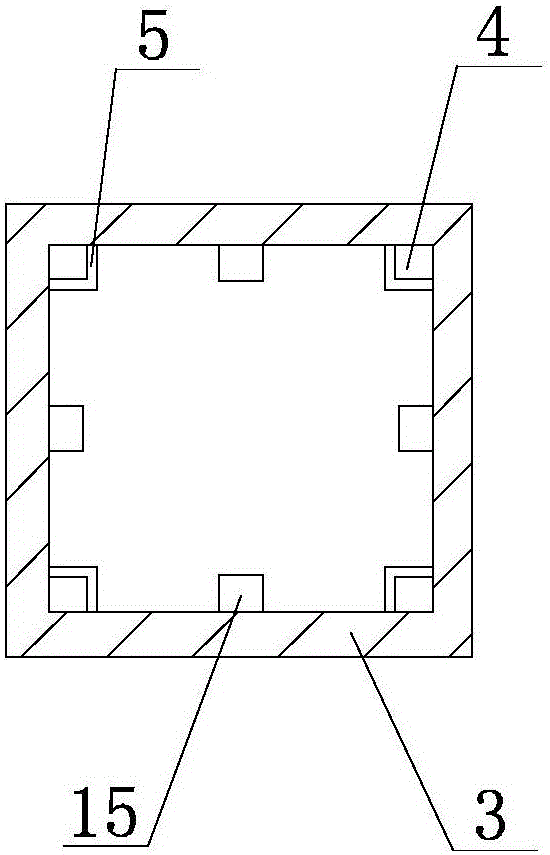

[0023] Specific implementation mode one: combine figure 1 , figure 2 , image 3 with Figure 4 Describe this embodiment, this embodiment comprises vertical combustion cylinder 3, horizontal combustion cylinder 7, reciprocating fire grate 1 and a plurality of temperature raising burners 2, and described vertical combustion cylinder 3 is vertically arranged, and vertical combustion cylinder 3 The top is the inlet end of fine-grained hazardous waste, and the inside of the vertical combustion tube 3 is a vertical combustion furnace, which is sequentially processed with a plurality of top burn-off air nozzles 4, a plurality of primary air nozzles 5 and A plurality of secondary air nozzles 6, the horizontal combustion cylinder 7 is obliquely arranged below the vertical combustion cylinder 3, the high end of the horizontal combustion cylinder 7 communicates with the bottom end of the vertical combustion cylinder 3, and the horizontal combustion cylinder 7 is connected to the botto...

specific Embodiment approach 2

[0055] Specific implementation mode two: combination figure 2 , image 3 , Figure 5 with Figure 6 To describe this embodiment, in this embodiment, a plurality of split burn-off air nozzles 15 are also processed on the cylinder wall of the vertical combustion cylinder 3 . This setting cooperates with multiple top burn-off air nozzles 4, multiple primary air nozzles 5 and multiple secondary air nozzles 6 to ensure that the four corners are tangentially circled and generate strong swirling flow, so that the vertical combustion tube 3 can fully burn High melting point characteristics.

[0056] It is feasible for the present invention to reach the temperature condition for melting hazardous wastes without adding auxiliary fuel, but some auxiliary means are needed. The calculation results show that the effect of increasing the furnace temperature by controlling the lower air excess coefficient is very limited. And increasing the air distribution ratio of primary air and seco...

specific Embodiment approach 3

[0058] Specific implementation mode three: combination figure 1 Describe this embodiment, in this embodiment, the end of the first discharge passage 10 communicating with the horizontal combustion tube 7 is set toward the bottom of the vertical combustion tube 3 . In this embodiment, the arrangement of the first discharge channel 10 and the horizontal combustion cylinder 7 in such a position can ensure the smooth discharge of ash and melt produced by the horizontal combustion cylinder 7, shorten the discharge path, reduce the processing time, and improve the processing efficiency. Other unmentioned structures and connection methods are the same as those in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com