3D house printer and printing method for printing concrete on construction site

A concrete and printer technology, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of low automation, low building construction efficiency, and high cost, and achieve high automation, low cost, and high work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with accompanying drawing.

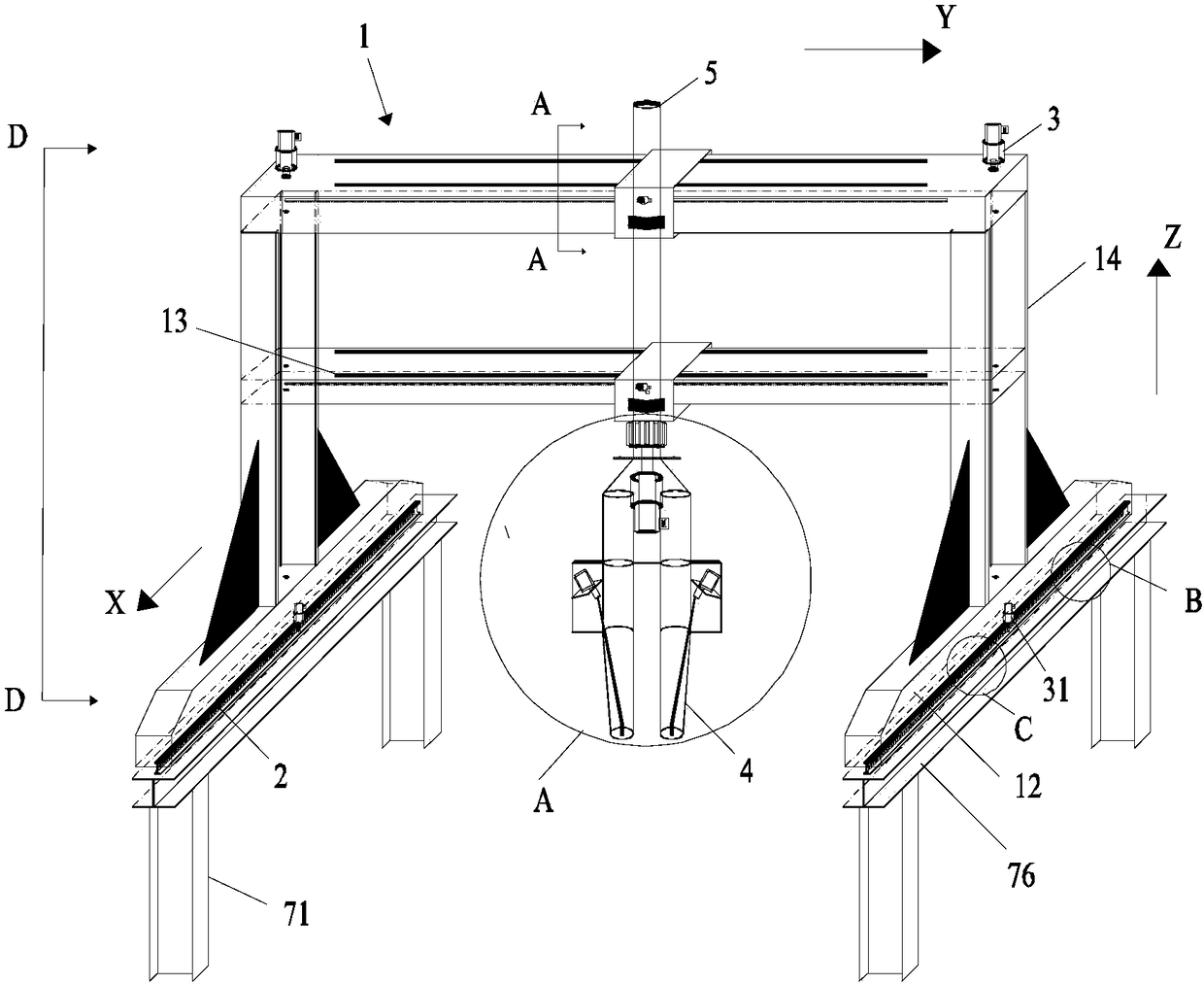

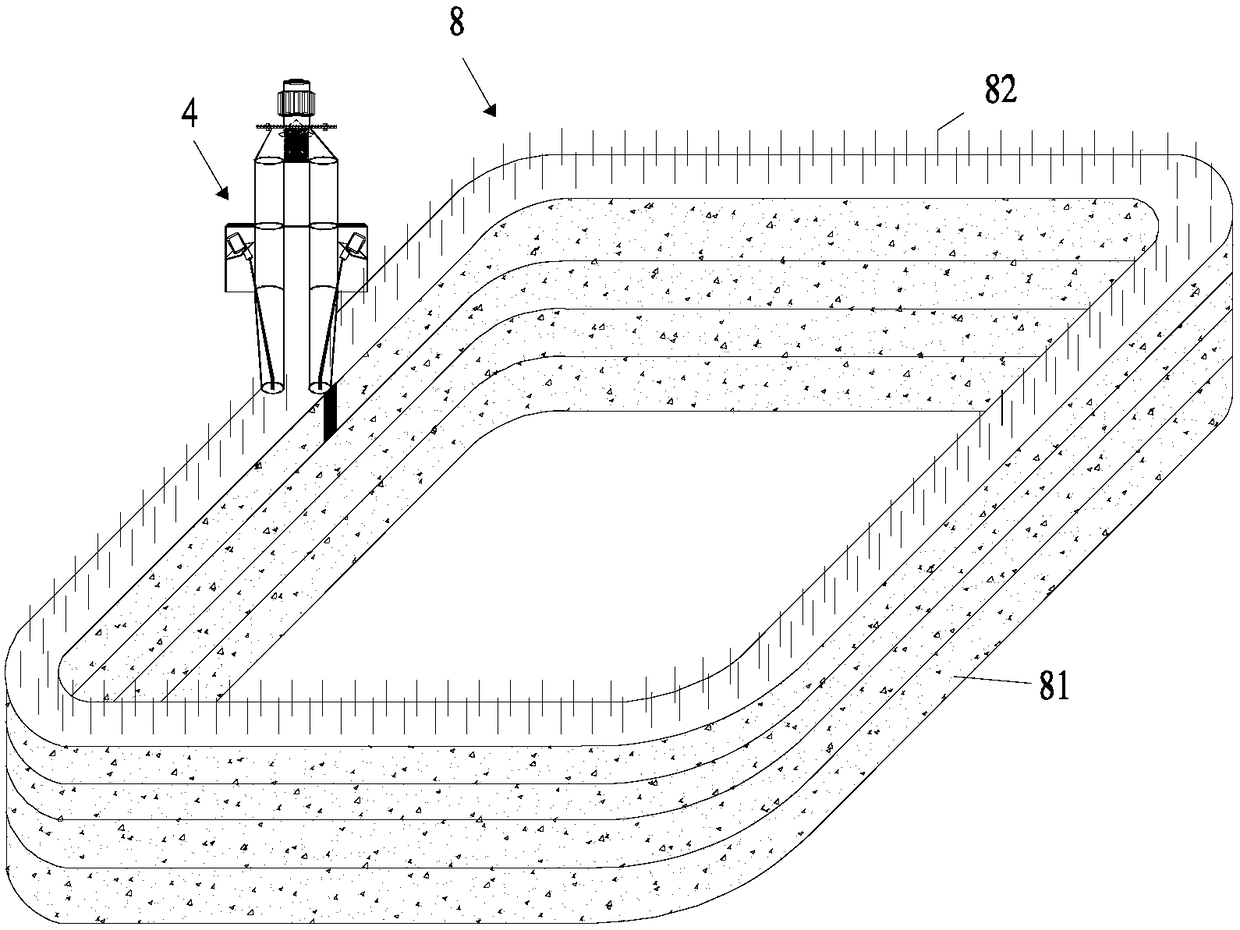

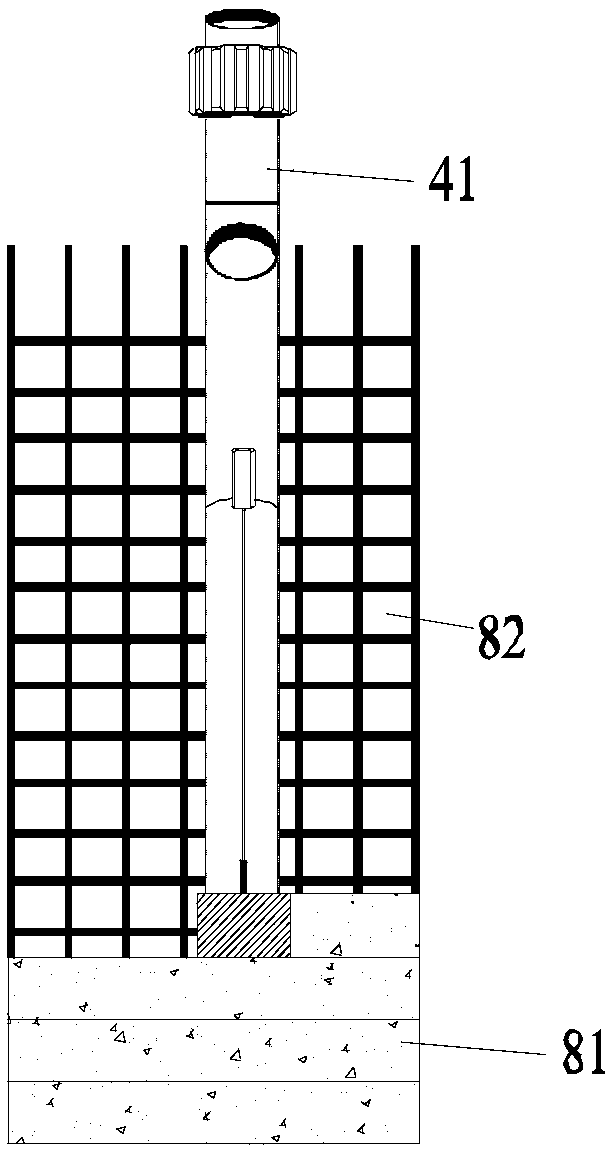

[0042] like figure 1 , figure 2 and image 3 As shown, the 3D house printer of the present invention is used to print a house 8 at a construction site. The house 8 printed by the 3D house printer can be used for residence, office, etc., and the house 8 can be a bungalow or a building. The 3D house printer includes a truss truck body 1 , a driving mechanism 3 respectively arranged on the truss truck body 1 , a traveling mechanism 2 connected to the driving mechanism 3 , and a concrete unloading assembly 4 arranged on the traveling mechanism 2 . When in use, the walking mechanism 2 drives the concrete unloading assembly 4 to walk along a set track. During the walking process, the concrete unloading assembly 4 unloads the concrete 81 to complete the construction of the house 8 . Before using the 3D house printer to print the concrete 81, the steel bars 82 can be arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com