Cotton carding method and device

A technology of carding and sliver, which is applied in the field of short-process spinning method and its device, carding method and its device, which can solve the problems of shortening, production speed mismatch, etc., and reduce accidental drafting and uneven weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

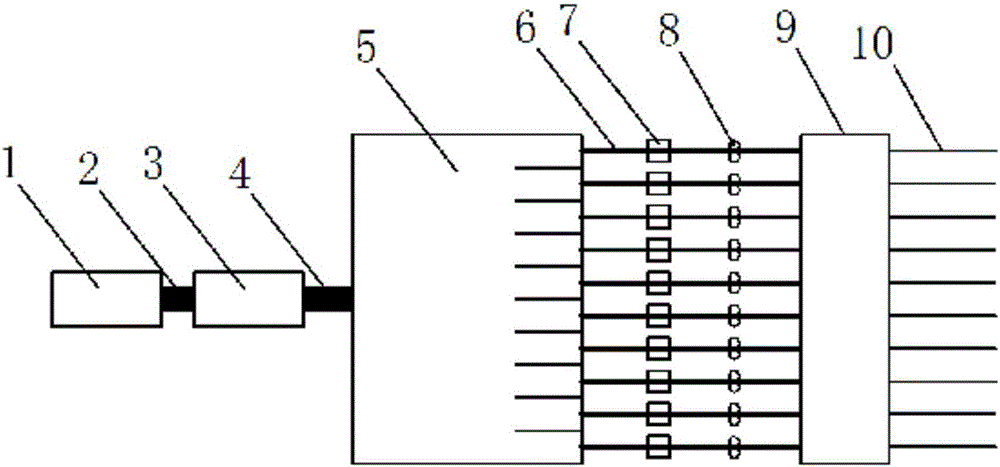

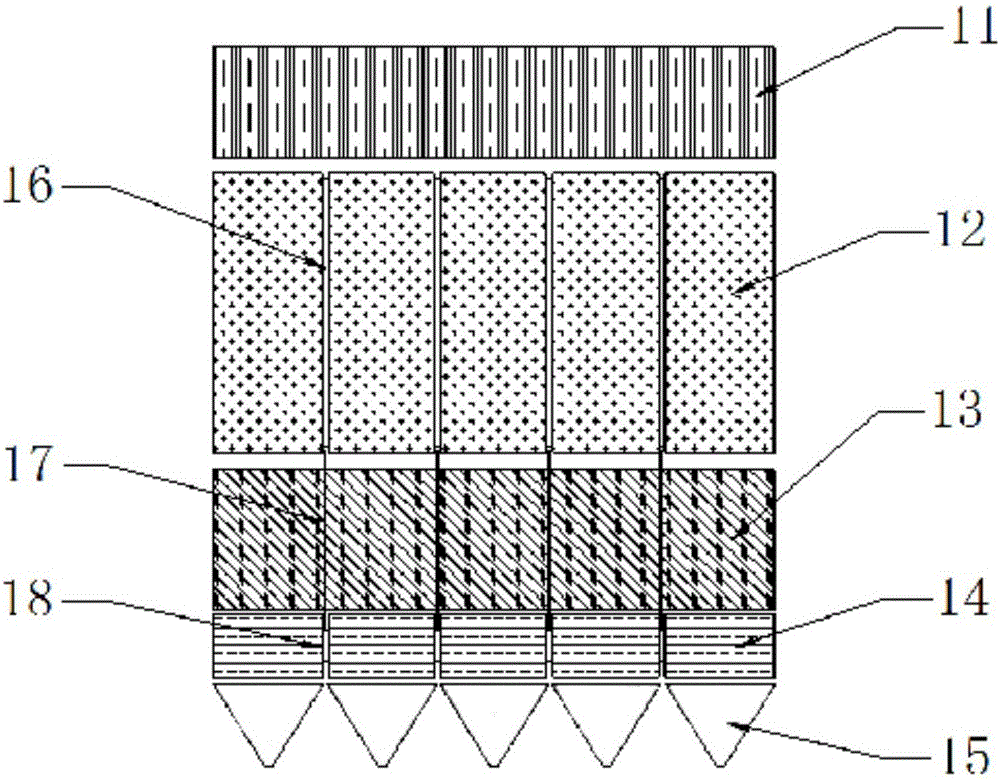

[0037] Technological process: A002D type disc plucking machine----A035 type mixed cotton opener----single machine multi-section carding machine----F1603 type rotor spinning machine.

[0038] Single-machine multi-section carding machine process: cylinder speed 300 rpm, licker-in speed 820 rpm, doffer speed 20 rpm, flat speed 140 mm / min, dust removal knife installation position -11 mm*105 degrees , The cylinder-cover gauge is 0.28 mm, 0.26 mm, 0.24 mm, 0.25 mm, 0.26 mm, and the cylinder-doffer gauge is 0.13 mm.

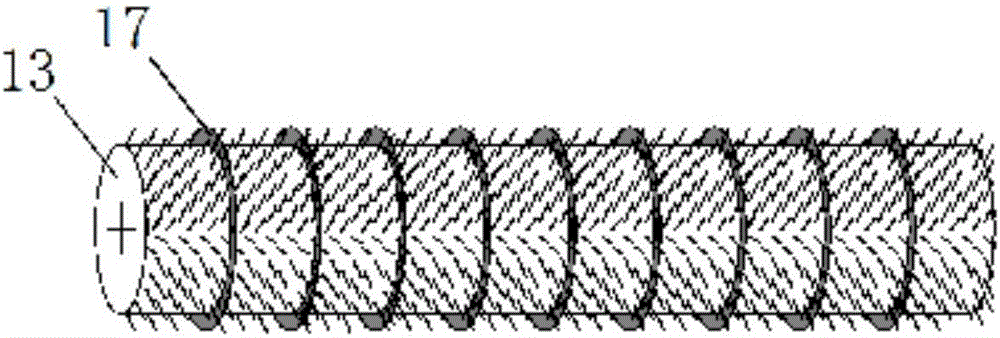

[0039] The rotating speed of the false twist disc of the false twister: 50 rpm.

[0040] Comparison of Yarn Quality of Rotor-spun Yarns with Different Yarn Counts

[0041]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com