Alkaline graphene-nickel electroplating liquid, and preparation method and application thereof

A technology of nickel electroplating solution and graphene solution, applied in electrolytic coatings, coatings and other directions, can solve the problems of uneven distribution of graphene, bright coating surface, poor flatness, loss of material surface protection, etc., and achieve the in-situ preparation method. Controllable, low cost, good protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

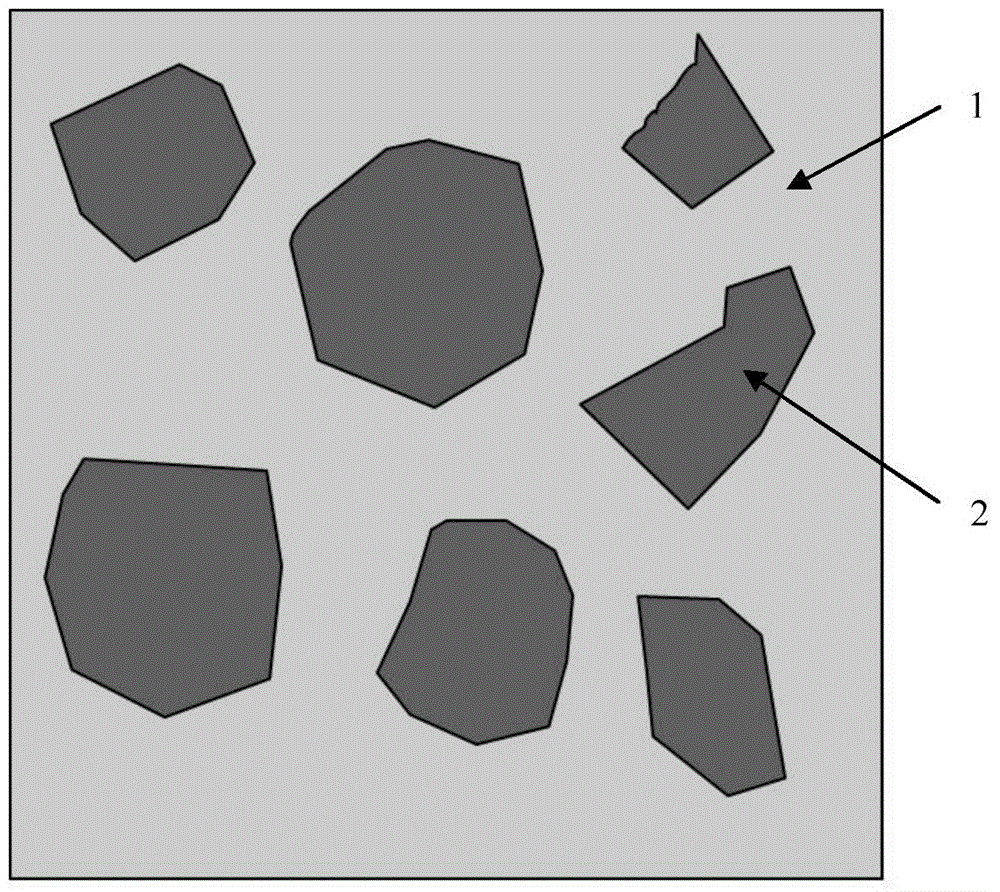

Image

Examples

preparation example Construction

[0033] Another aspect of the present invention provides a kind of preparation method of alkaline graphene-nickel electroplating solution, comprising:

[0034] providing a nickel electroplating solution comprising a nickel salt and a complexing agent;

[0035] Provide electroplating graphene solution, described electroplating graphene solution comprises stabilizer, reducing agent and the graphene that is uniformly dispersed in described electroplating graphene solution;

[0036] And, uniformly mixing the nickel electroplating solution and the graphene electroplating solution, and then adjusting the pH value of the mixed solution to 9-14 with an alkaline substance, so as to obtain the alkaline graphene-nickel electroplating solution.

[0037] Another aspect of the present invention provides the use of the alkaline graphene-nickel electroplating solution to prepare a graphene-nickel composite coating on the metal surface of an article.

[0038] The aforementioned items may be me...

Embodiment 1

[0058] In the present embodiment, the solvent of alkaline graphene-nickel electroplating solution is deionized water, and comprises: nickel sulfate 20g / L, hydrazine hydrate 5g / L, boric acid 10g / L, dimethyl sulfoxide 20g / L, Graphene 1mg / L.

[0059] Use above-mentioned plating solution to prepare the technique of graphene-nickel composite coating as follows:

[0060] (1) The metal substrate is low-carbon steel; the surface of the metal substrate is pretreated to remove oil and oxide film. The specific process is: add an appropriate amount of sodium lauryl sulfate to a NaOH solution with a concentration of 10% by mass to obtain a mixed solution, the concentration of sodium lauryl sulfate in the mixed solution is 1g / L, put the metal substrate into the mixed solution, wash at a cleaning temperature of 50°C for 8 minutes, and then use mechanical polishing to oxidize the surface of the metal substrate Membrane removal treatment;

[0061] (2) Use deionized water to prepare nickel su...

Embodiment 2

[0068] In this embodiment, the solvent of the alkaline graphene-nickel electroplating solution is deionized water, and contains: nickel chloride 15g / L, citric acid 10g / L, dimethylaminoborane 6g / L, dimethylaminoborane Formamide 10g / L, graphene 0.1mg / L.

[0069] Use above-mentioned alkaline graphene-nickel electroplating solution to prepare the technique of graphene-nickel composite coating as follows:

[0070] (1) The metal substrate is low-carbon steel; the surface of the metal substrate is pretreated to remove oil and oxide film. The specific process is: add an appropriate amount of sodium lauryl sulfate to a KOH solution with a concentration of 15% by mass to obtain a mixed Solution, the concentration of sodium lauryl sulfate in the mixed solution is 5g / L, the metal substrate is put into the mixed solution, cleaned at a cleaning temperature of 60°C for 5 minutes, and then the surface of the metal substrate is oxidized by chemical polishing Membrane removal treatment;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com