Aging technology for aging vinegar

An aging and vinegar technology, which is applied in the field of vinegar aging and aging technology, can solve the problems of need for optimization, low production efficiency, long time consumption, etc., to increase the content and ratio of esters and the like, and reduce irritating substances. The effect of content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

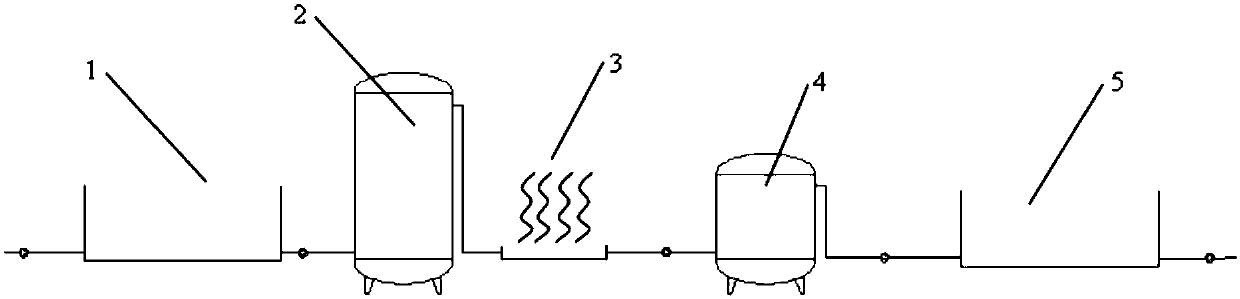

[0020] A combined aging process of vinegar controlled by ultrasonic temperature, the specific method is as follows:

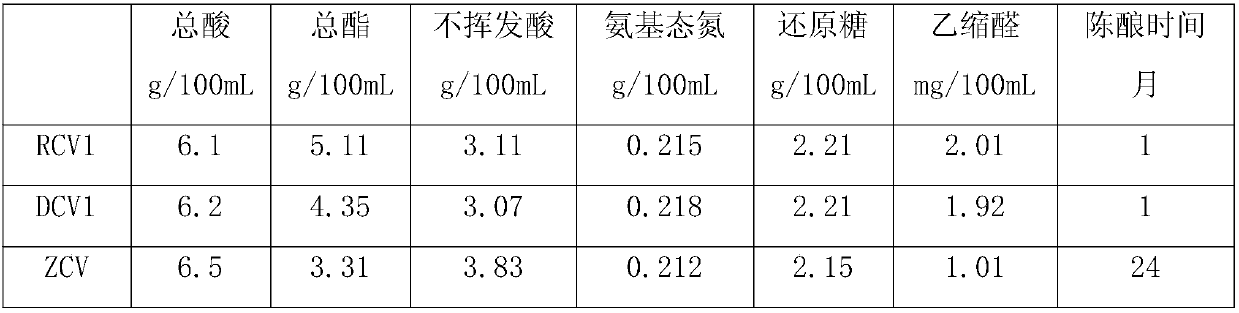

[0021] Pump the vinegar in the vinegar storage tank into the ultrasonic aging tank for ultrasonic aging, control the tank temperature at 30-34°C, ultrasonic frequency 20kHz, power 500w, and control the duration of vinegar flowing through the ultrasonic aging tank at 20 minutes; infrared When aging, the infrared power is 150w, the depth of the infrared irradiation shallow pool is 5cm, and the irradiation height is 15-20cm. The total time for the vinegar to flow through the infrared irradiation area is 30min; The duration of the vinegar flowing through the microwave aging tank is 3 minutes; after the vinegar is artificially aged, it is pumped into the vinegar drying pool for vinegar aging, and the vinegar is kept in the sun for 1 month. aged vinegar.

Embodiment 2

[0031] A vinegar aging and accelerating process carried out according to the sequence of ultrasonic wave, infrared and microwave, the specific method is as follows:

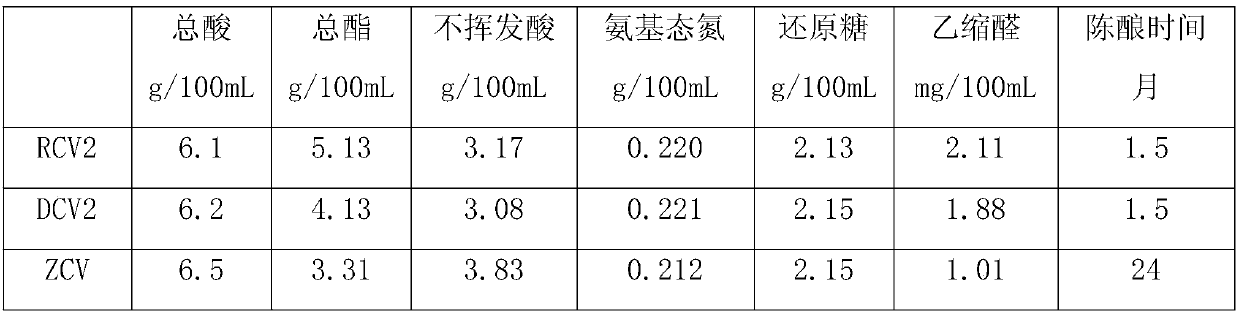

[0032] Pump the vinegar in the vinegar storage tank into the ultrasonic aging tank for ultrasonic aging, control the tank temperature at 34-37°C, ultrasonic frequency 22kHz, power 600w, and control the duration of vinegar flowing through the ultrasonic aging tank at 25 minutes; The vinegar is subjected to infrared aging, the infrared power is 180w, the shallow pool depth of infrared radiation is 8cm, and the irradiation height is 15-20cm. The total time for the vinegar to flow through the infrared irradiation area is 40min; finally, the vinegar is pumped into the microwave aging The device carries out microwave aging, the microwave frequency is 1000MHz, and the microwave power is 720w. The maintenance time of vinegar flowing through the microwave aging tank is controlled to be 4 minutes; after the vinegar is artif...

Embodiment 3

[0042] A process for combining aging and aging of vinegar by using ultrasound, infrared and microwave, the specific method is as follows:

[0043] Pump the vinegar in the vinegar storage tank into the ultrasonic aging tank for ultrasonic aging, control the temperature of the tank body at 37-40°C, the ultrasonic frequency at 25kHz, and the power of 700w, and control the duration of vinegar flowing through the ultrasonic aging tank at 30 minutes; after that The vinegar is subjected to infrared aging, the infrared power is 200w, the depth of the infrared irradiation shallow pool is 10cm, and the irradiation height is 15-20cm. The total time for the vinegar to flow through the infrared irradiation area is 50min; finally, the vinegar is pumped into the microwave aging The device carries out microwave aging, the microwave frequency is 1450MHz, and the microwave power is 750w. The maintenance time of the vinegar flowing through the microwave aging tank is controlled to be 5 minutes; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com