High strength pre-stressed concrete pipe pile and preparation method thereof

A technology for concrete pipe piles and prestressing, which is applied in the field of high-strength prestressed concrete pipe piles and their preparation, and can solve the problems of confusing formula and increasing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with the examples, the present invention is further described, the following examples are illustrative, not limiting, and the protection scope of the present invention cannot be limited by the following examples.

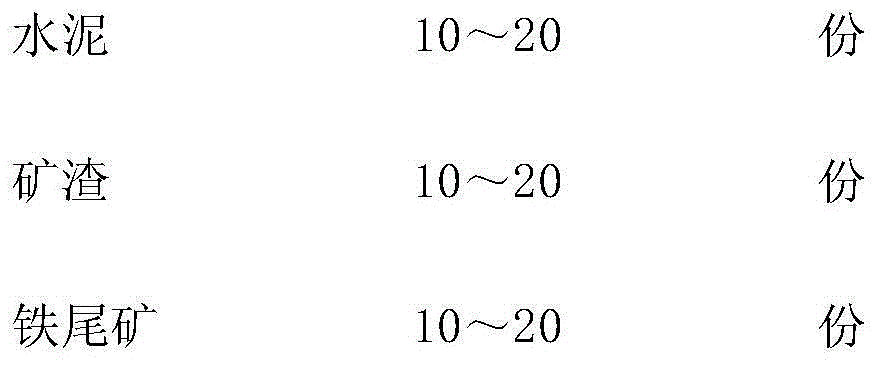

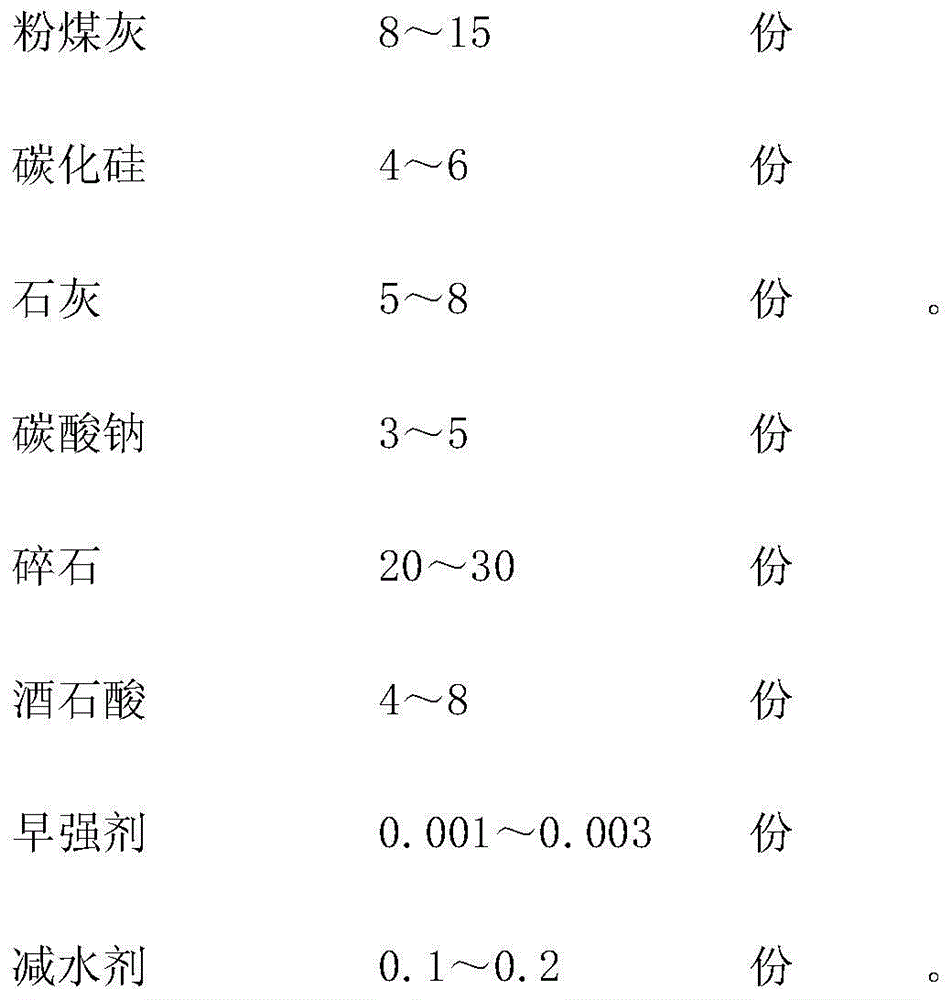

[0017] A high-strength prestressed concrete pipe pile, the innovation of the present invention lies in: including the following components mixed in parts by weight:

[0018]

[0019]

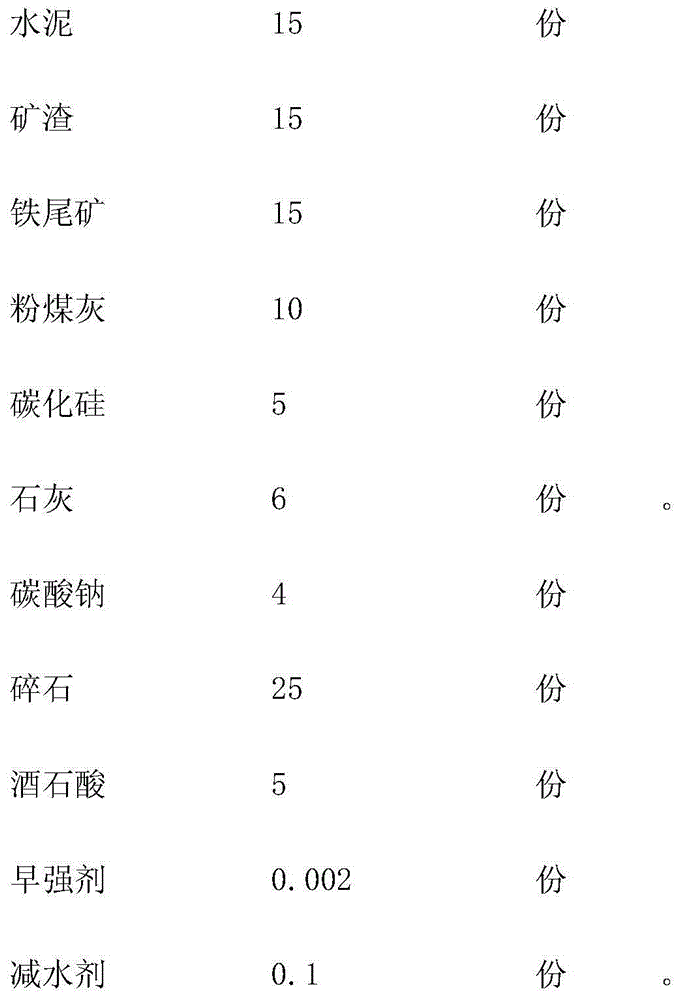

[0020] A more preferred scheme is: include the following components mixed in parts by weight:

[0021]

[0022] The preparation method of the above-mentioned high-strength prestressed concrete pipe pile comprises the following steps:

[0023] (1) Weigh cement, slag, iron tailings, fly ash, silicon carbide, lime, sodium carbonate, crushed stone, tartaric acid, early strength agent and water reducer according to the measurement, mix each material with water and add to the mixer;

[0024] ⑵Put the reinforcement cage in the mold, then add the product ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com