Li-ion battery separator slitting machine

A slitting machine and diaphragm technology, which is applied in the direction of winding strips, sending objects, thin material processing, etc., can solve the problems of uneven sides of the diaphragm, poor slitting effect, large tension, etc., to achieve neat end faces and stable winding. , the effect of eliminating wrinkles and streaks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described below in conjunction with specific embodiments.

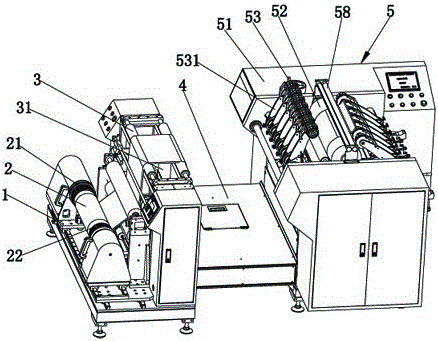

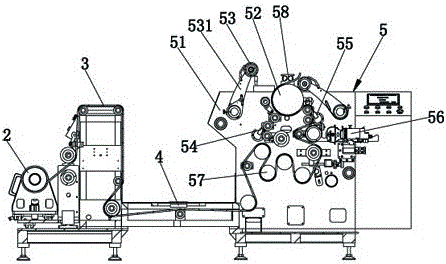

[0018] Such as Figure 1-2 As shown, a lithium battery diaphragm slitting machine includes an edge correction platform mechanism 1 that can translate left and right. The upper end of the edge correction platform mechanism 1 is equipped with an air expansion shaft unwinding mechanism 2, and the upper right side of the air expansion shaft unwinding mechanism 2 A defect detection platform 3 is installed, and the lower end of the right side of the defect detection platform 3 is equipped with a horizontally arranged transition mechanism 4, and the right end of the transition mechanism 4 is equipped with a winding mechanism 5, and the winding mechanism 5 includes a winding frame 51, The upper end of the winding frame 51 is equipped with a winding main roller 52 arranged horizontally, the left and right sides of the winding main roller 52 are equipped with a slip ring locking device 53, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com