car rear subframe

A rear subframe and automobile technology, applied to vehicle components, substructure, transportation and packaging, etc., can solve the problems of low overall modality of the rear subframe, low rigidity of the installation point and low load-bearing capacity, and achieve light weight Effects of quantization, compactness, and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

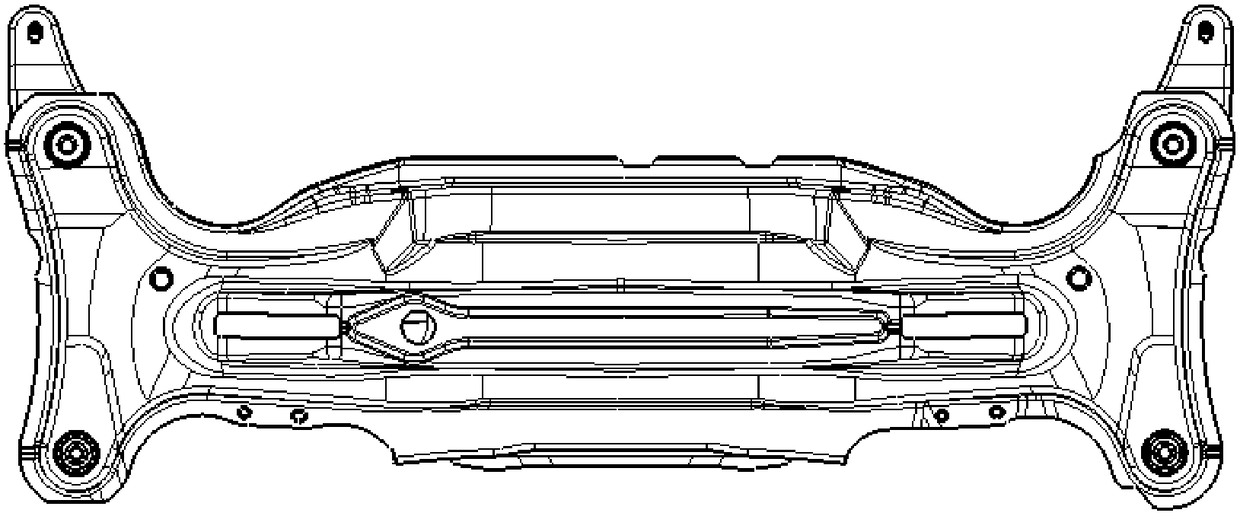

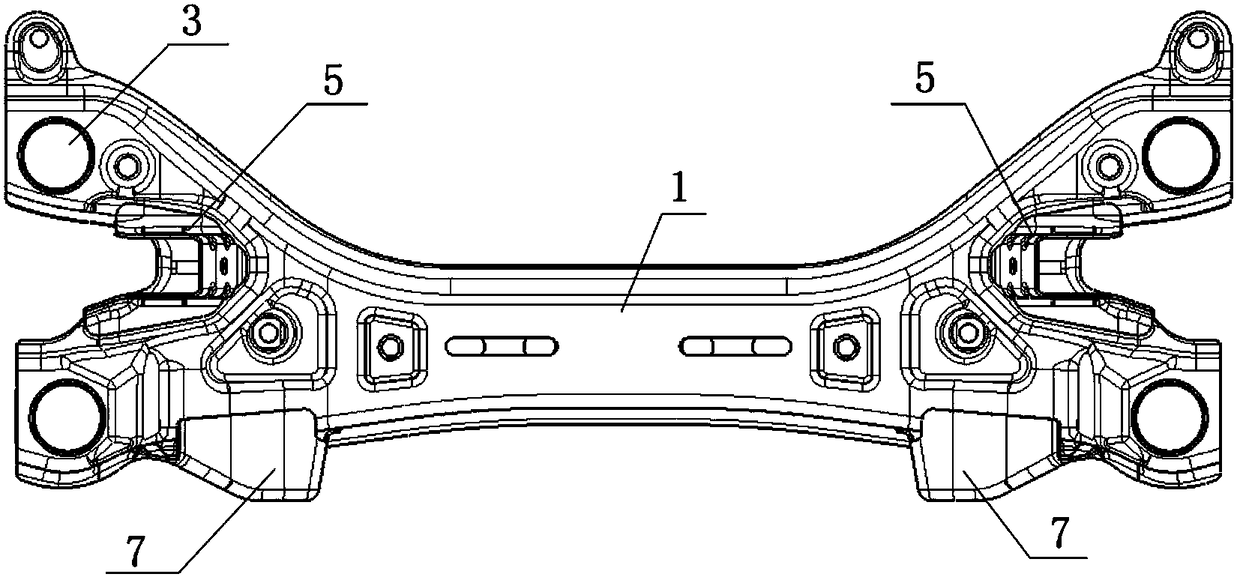

[0028] like figure 2 and image 3 As shown, an automobile rear subframe provided by the embodiment of the present invention includes a main body plate 1 and a connecting plate 2. The main body plate 1 is bone-shaped with large ends and a small middle, so that the rear subframe takes up space. It is greatly reduced, the weight is greatly reduced, and a considerable space is avoided in the middle position, which provides great convenience for the arrangement and installation of other systems, such as fuel tanks and exhaust systems. The cross section of the main board 1 is The first groove-shaped structure with the opening facing downwards, the connecting plate 2 is locate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com