Pipe cutting device

A technology of pipe cutting equipment and cutting platform, which is applied in metal processing and other directions, can solve the problems of waste, low cutting accuracy, time-consuming and labor-intensive, etc., and achieve the effects of avoiding waste, facilitating the cutting process, and facilitating cutting operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

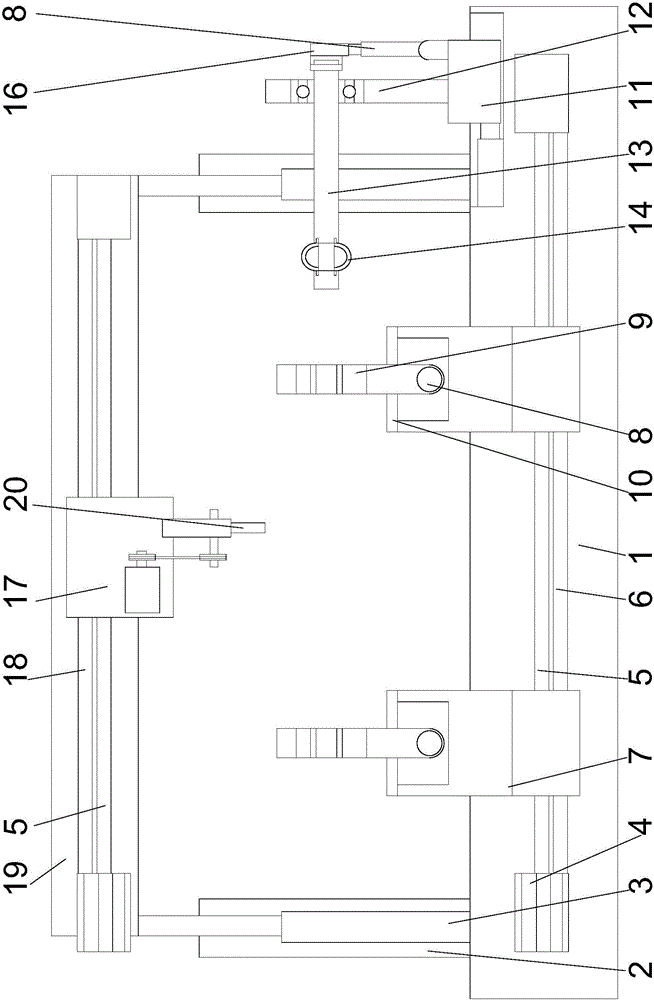

[0023] Such as figure 1 Shown, a kind of pipe material cutting equipment comprises a base 1 and a beam 19 arranged on the base, a cutting unit is arranged on the beam, a motor 4 is arranged on the base, and a motor 4 is arranged on the base. A screw 5 is arranged on the rotating shaft of the screw, a fixed shaft 6 is arranged under the screw, a tray 7 is arranged on the screw, and the tray is set on the screw and the fixed shaft. On the shaft, two hydraulic cylinders 8 facing each other are arranged on the pallet, positioning buckles 9 are respectively arranged on the telescopic rods of the two hydraulic cylinders, and the lower ends of the positioning buckles are fixedly connected to the On the hydraulic cylinder, the upper end of the positioning buckle is semicircular, and a circular structure is formed between the positioning buckles on the two hydraulic cylinders;

[0024] The cutting unit includes a cutter 20 and a motor arranged on one side of the cutter, the cutter is ...

Embodiment 2

[0028] In this embodiment, on the basis of Embodiment 1, in order to facilitate the rotation of the pipe when needed and to facilitate full cutting, preferably, a slider 11 is provided above the side of the base, and the slider 11 can be moved along the The above-mentioned base slides, a bracket 12 is arranged above the slider, and a cross bar 13 is arranged on the described bracket. One end of the bar is provided with a buckle 14, the buckle is made of sheet metal, and the middle part of the buckle is arched toward the outside of the cross bar. Move the slider so that the slider drives the bracket to move towards the direction of the pipe, so that the cross bar set on the bracket is inserted into the inside of the pipe, and the buckle set on the cross bar is snapped on the inner wall of the pipe, so that the two hydraulic cylinders on the pallet The telescopic rod shrinks, the positioning buckle moves in the opposite direction, and the cross bar is rotated so that the cross b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com