Multifunctional oil cylinder disassembly table

A dismantling table and multi-functional technology, applied in the direction of hand tools, manufacturing tools, etc., can solve the problems of complex structure, secondary damage of parts, difficult disassembly and assembly, etc., and achieve simple and reasonable structural design and low risk of component damage , the effect of improving labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further understand the content of the invention, features and effects of the present invention, the following examples are given in detail as follows:

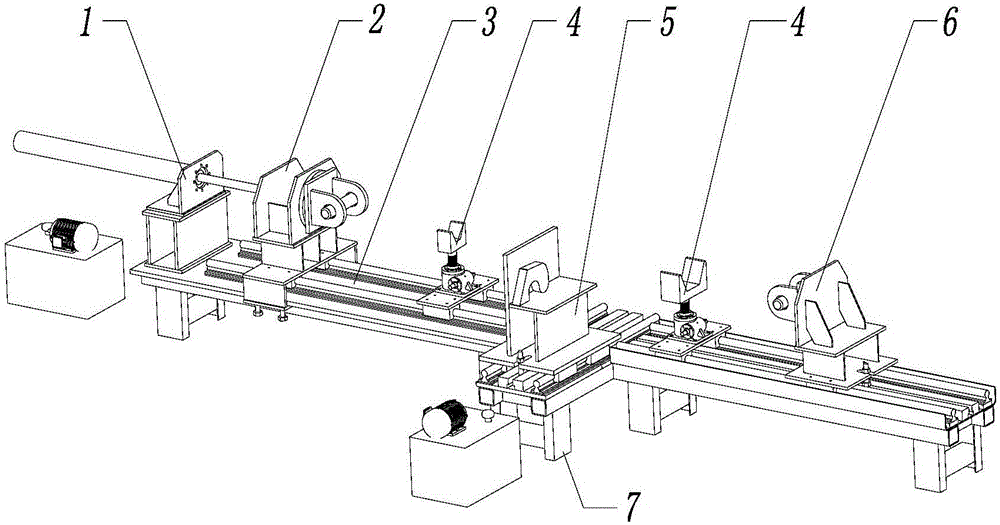

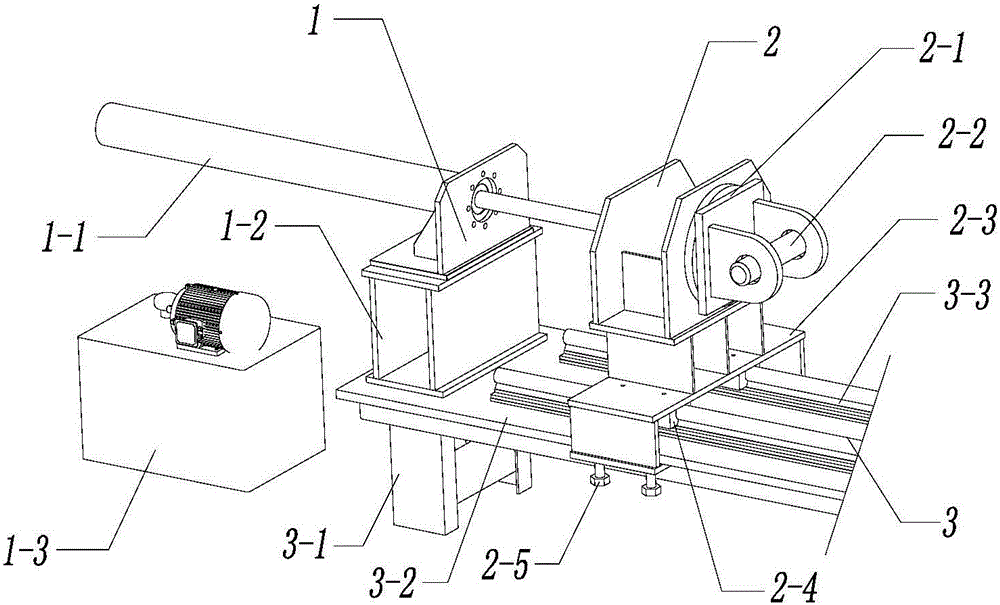

[0025] See figure 1 , the oil cylinder dismantling platform of the present invention comprises the main frame 3 that the top is fixedly installed with the first guide rail 3-3 extending along the length direction, and the side frame 7 is fixedly installed in the middle part of the main frame 3, and on the top of the side frame 7 A second guide rail 7-2 extending along the length direction is fixedly installed, and the first guide rail 3-3 and the second guide rail 7-2 are perpendicular to each other.

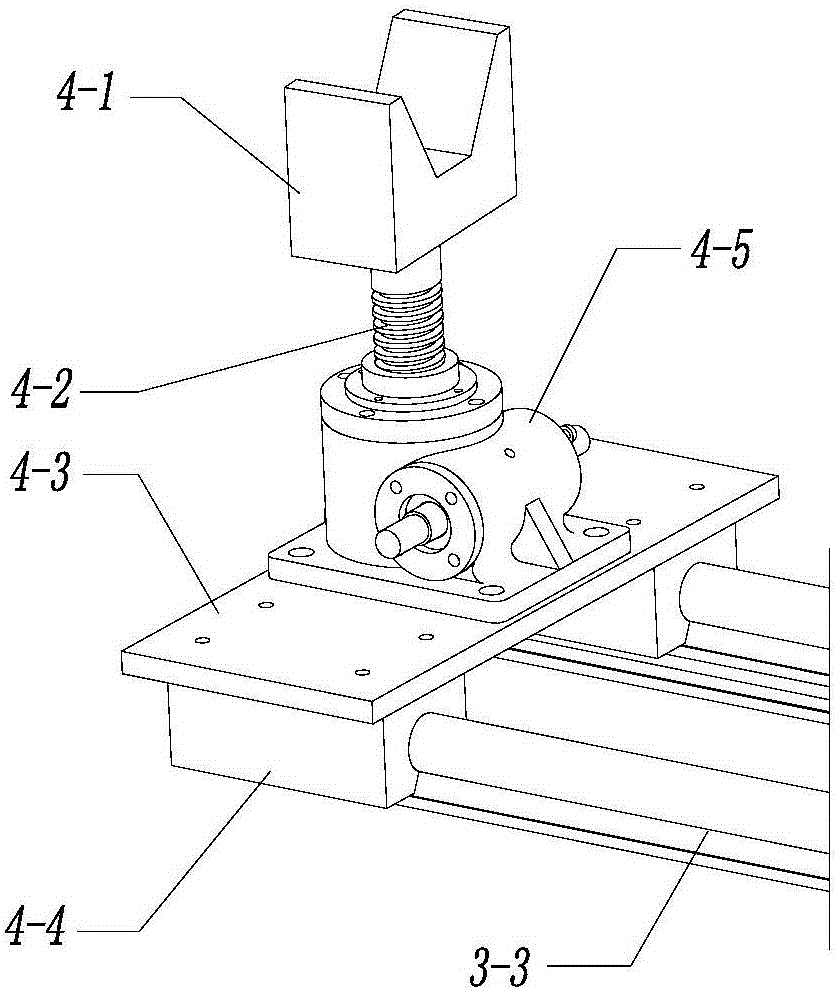

[0026] The head end of the first guide rail 3-3 is provided with a movable and fixed cylinder rod stretching device 2, and the tail end is provided with a movable and fixed cylinder barrel stretching device 6, behind the cylinder rod stretching device 2, A movable support device 4 is provided in front of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com