Rotary type sand mold three-dimensional printer

A three-dimensional printer and rotary technology, applied in the directions of casting molds, cores, casting mold components, etc., can solve the problems of non-continuous motion and low efficiency, and achieve the effect of saving time and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below with reference to the accompanying drawings and examples.

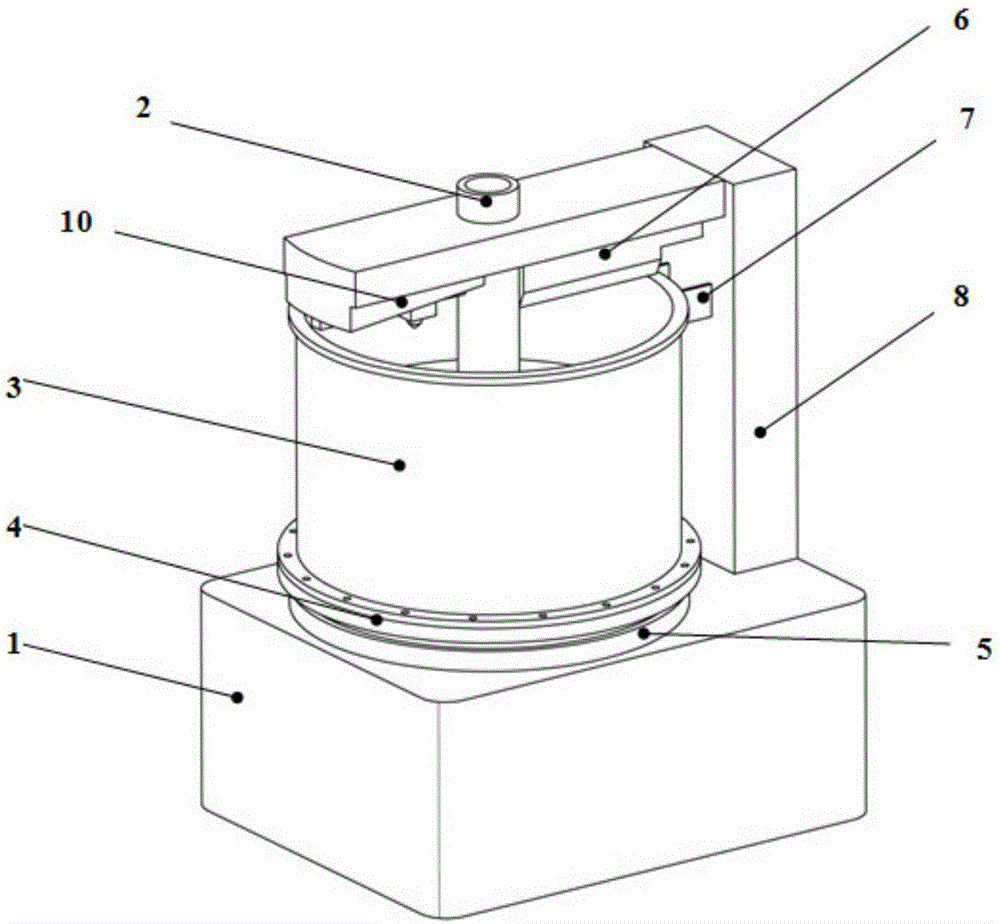

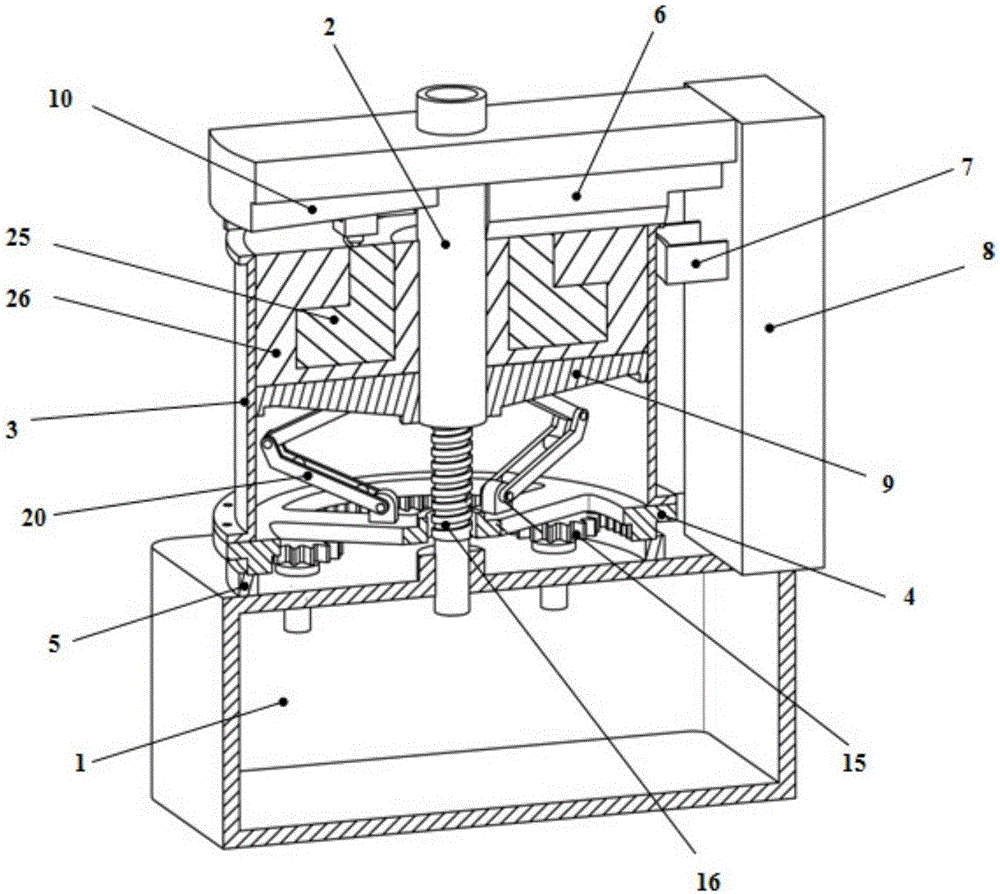

[0021] Such as figure 1 and figure 2 As shown, according to the rotary sand-type three-dimensional printer of the present invention, an axial contact bearing 5 is installed on the base 1, the upper part of the bearing 5 is connected with the cylindrical working cylinder 3, and the circular working table 9 is arranged inside the working cylinder 3. The connecting rod mechanism 20 connects the working cylinder 3 with the workbench 9, the hollow rod 2 equipped with the lead screw nut 17 is fixedly connected with the workbench 9, connects with the base 1 through the lead screw 16, and the sand shop 6 moves with the printing head The mechanism 10 is located on the top of the working cylinder 3 and fixedly connected with the base 1 through the bracket 8 .

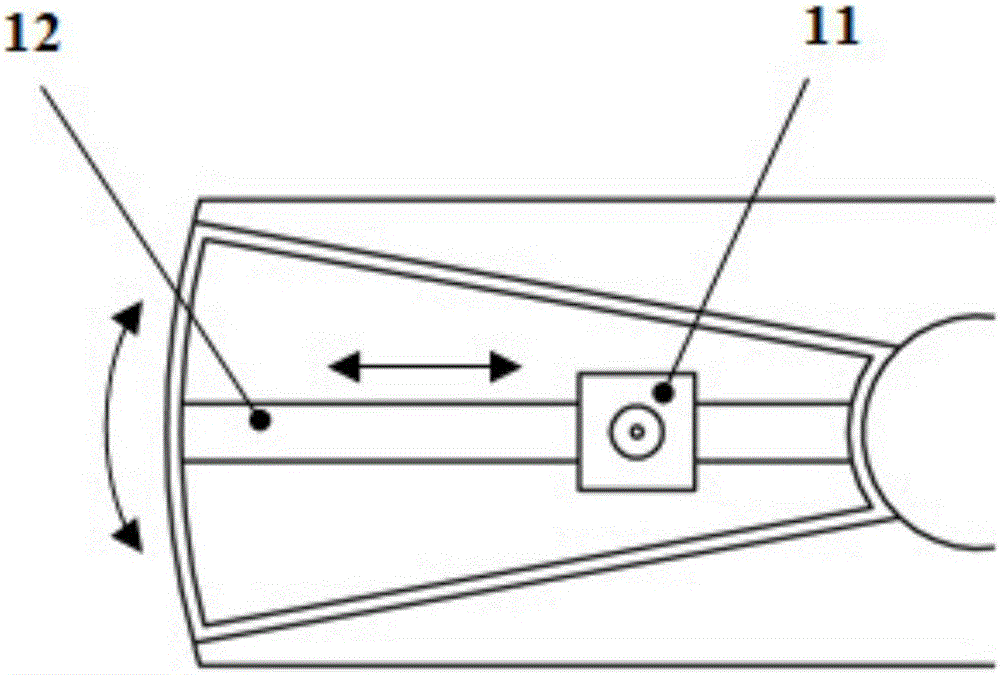

[0022] Such as figure 2 , Figure 4 and Figure 5 As shown, at least three link mechanisms 20 are u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com