Internal diameter spraying treatment machine

A processor, ID technology used in pre-treatment of surfaces, coatings, spray devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

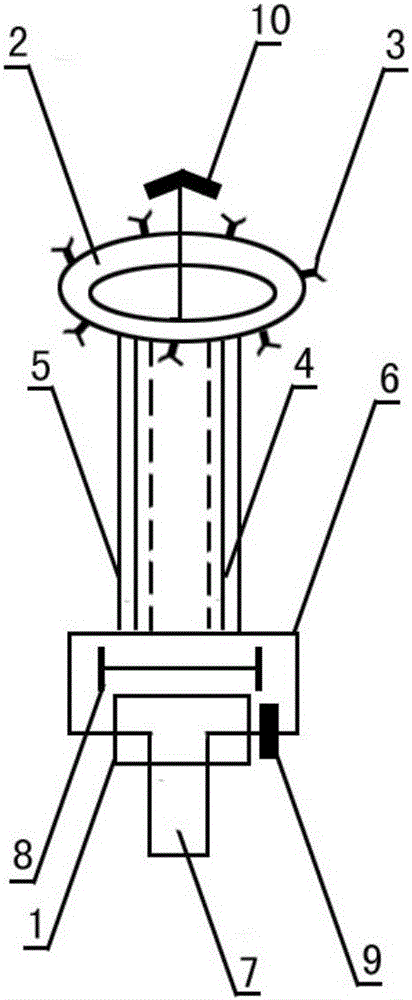

[0012] Embodiment: as shown in the accompanying drawing. An inner diameter spraying processor, comprising a body (1), the whole body (1) has a telescopic structure design, a circular empty pipe device (2), a sprinkler head (3) are arranged at the front end, and the pipe body and the elongated hollow pipe device ( 4) Connection, the suspended brackets (5) are located on both sides of the pipe body, and the lower end is provided with a cover device (6), a connection slot (7), and a handrail device (8). When in use, start the pressure pump (9) to apply the anticorrosive paint The filling pipeline is stretched into the circular object, and the handrail device (8) is pulled to carry out the mobile spraying operation.

[0013] An inner-diameter spraying processor is provided with a drying lamp assembly (10), which runs through the middle of a circular empty pipe device (2), and is in a retractable suspended state.

[0014] An inner-diameter spraying processor, a casing device (6) a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com