A grinding roller device with a flexible connection structure

A technology of flexible connection and grinding rollers, applied in the field of coal mill manufacturing, can solve the problems of the strength and shear resistance being difficult to reach the expected service life, connecting bolts directly hitting the grinding bowl device, difficulty in production, and service life, etc. Improve the service life and safety performance, solve the effect of easy breakage, and meet production needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

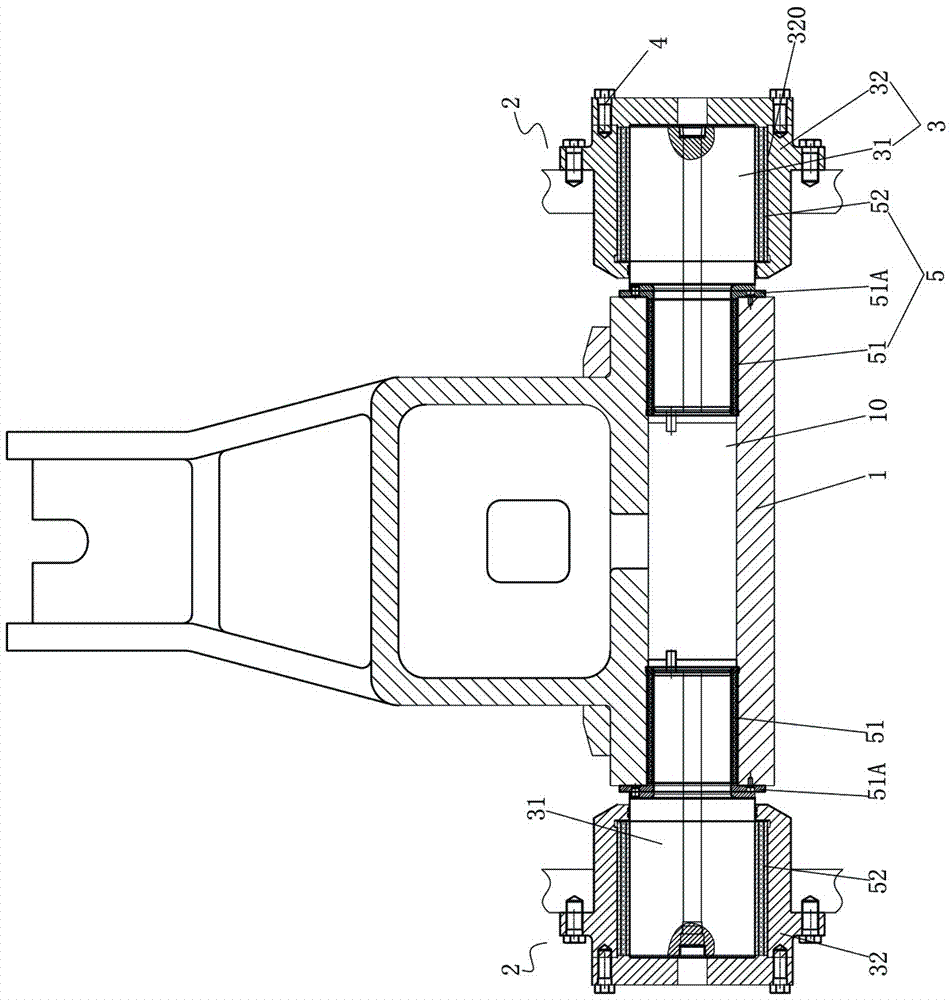

[0020] Specific embodiments, the grinding roller device with a flexible connection structure according to the present invention mainly includes the following components: a grinding roller head 1, a separator body device 2, a shaft body 31, an attachment seat 32 and a shaft sleeve 5;

[0021] During actual production and assembly, the grinding roller head 1 adopts a cast steel structure as a whole, and the two ends of the grinding roller head 1 are extended in the direction of the connecting seat 32 to the length required for modification, and then the lengthened ends are processed to the required depth for modification and the hole position 10 of diameter (according to the force analysis and calculation of each model), and the shaft sleeve 5 with the anti-collision part 51A is packed into the processed hole position 10;

[0022] The shaft body 31 is redesigned and processed into a shaft diameter tightly matched with the holes 320, 10, wherein the shaft diameter corresponding to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com