Method for preparing catalyst used for modulating distribution of metal on molecular sieve

A molecular sieve and catalyst technology, which is applied in the field of catalyst preparation for modulating the spatial distribution of metal nanoparticles on a molecular sieve carrier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] On the one hand, a method for preparing a catalyst that modulates the distribution of metals on molecular sieves, the specific steps are as follows:

[0041] (1) pre-mixing the pore blocking agent with the molecular sieve I to obtain the molecular sieve II filled with the pore blocking agent molecules in the channels;

[0042](2) mixing and stirring the metal precursor solution and the molecular sieve II to obtain a mixed solution I;

[0043] (3) Adjust the pH value of the mixed solution I to be less than or equal to the isoelectric point of the element at the deposition position on the molecular sieve I, then age, centrifuge, and dry to obtain the catalyst A.

[0044] In catalyst A, the pores of molecular sieve I have been blocked by plugging agent molecules. After the metal precursor solution is mixed with molecular sieve II, the metal species will preferentially contact and react with the molecular sieve at the pores, making the pores blocked and Au species difficult...

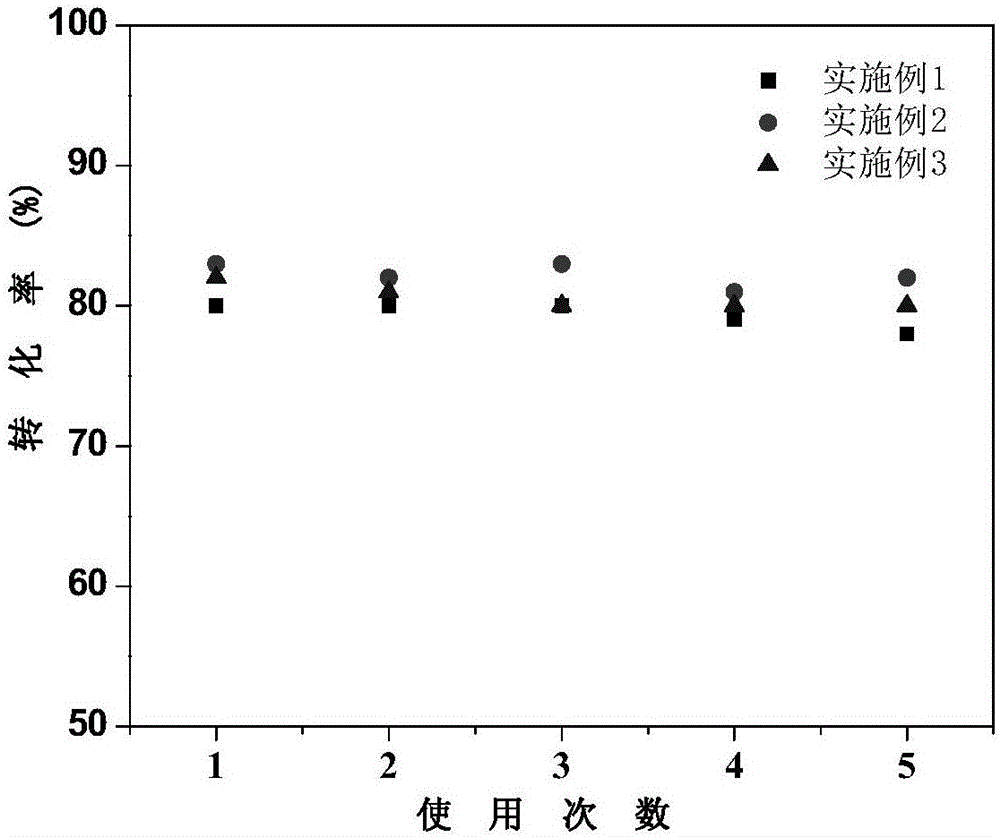

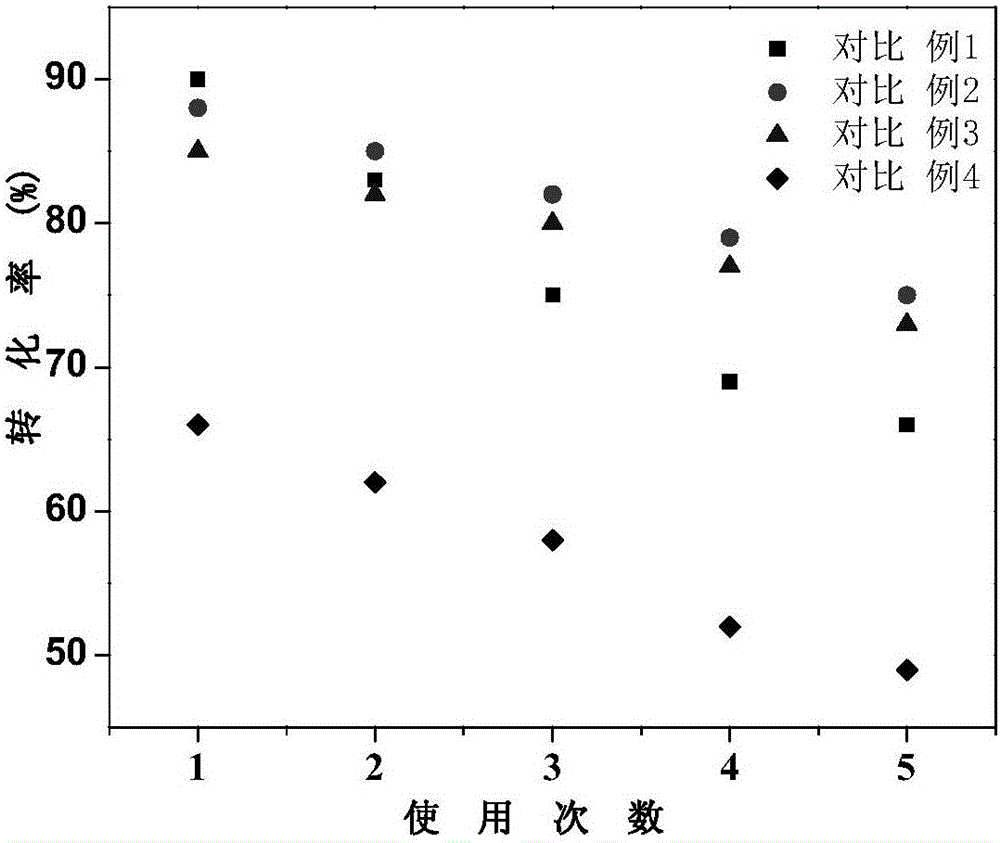

Embodiment 1

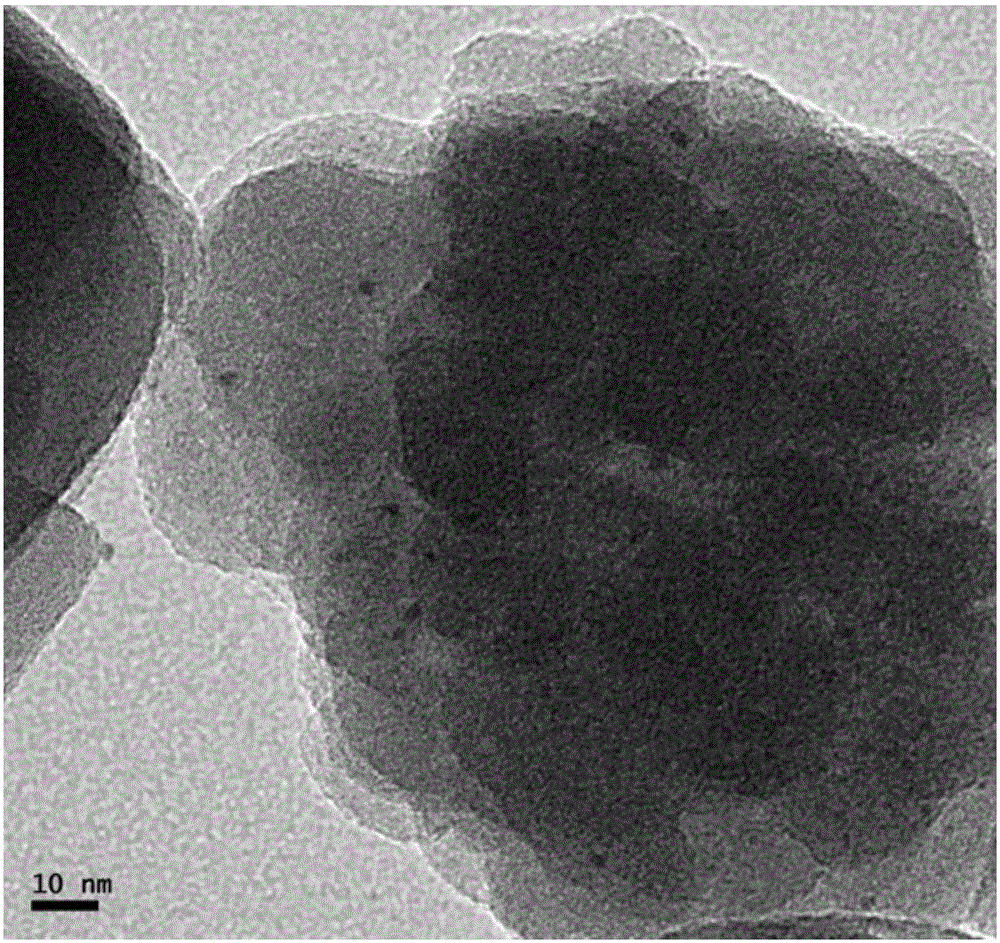

[0075] Deposition of Au nanoparticles on specific Ti sites on the outer surface of molecular sieves

[0076] Take 0.5g of titanium silicon molecular sieve TS-1 containing tetraethylammonium hydroxide and place it in a beaker, add 40g of water and stir for 10 minutes, then add 10mL of 0.1mol / L chloroauric acid solution to form mixed solution I; mix solution I Stirring at room temperature for 30 minutes and maintaining the pH at 7, centrifuging the obtained mixed solution, washing, and drying to obtain a catalyst in which Au nanoparticles are only deposited near the Ti site on the outer surface of the titanium-silicon molecular sieve TS-1.

[0077] Carry out N 2 Physical adsorption, as shown in Table 1. Compared with the micropore volume of Au / TS-1, the micropore volume of the pure carrier TS-1 is almost unchanged, and both are small, indicating that the template agent blocks the micropore channels, and the Au nanoparticles are only deposited outside the molecular sieve. surfa...

Embodiment 2

[0080] Deposition of Au nanoparticles on specific Ti sites on the outer surface of molecular sieves

[0081] Take 0.5g of titanium-silicon molecular sieve TS-1 containing no pore-blocking agent in the micropores and place it in a beaker, add 40g of water at 60°C and stir for 100 minutes, then add 10mL of 0.1mol / L chloroauric acid solution to form a mixed solution I ; The mixed solution I was stirred at room temperature for 50 minutes and the pH was maintained at 7, the mixed solution was centrifuged, the solid was taken out, washed and dried to obtain a catalyst in which Au nanoparticles were only deposited near the Ti site on the outer surface of the titanium-silicon molecular sieve TS-1 .

[0082] Carrying out N on TiSi molecular sieve TS-1 and Au / TS-1 catalysts without pore-blocking agent in the micropores 2Physical adsorption, as shown in Table 1. Although the micropore volume of the pure carrier TS-1 is larger than that of Au / TS-1, it hardly changes, indicating that the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com