Wetting agent for pesticide preparation, preparation method thereof and application in pesticide preparation

A technology for pesticide preparation and wetting agent, which is applied in the field of pesticide preparation wetting agent and its preparation, achieves the effects of low production cost, no three-waste pollution, and strong synthetic variability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

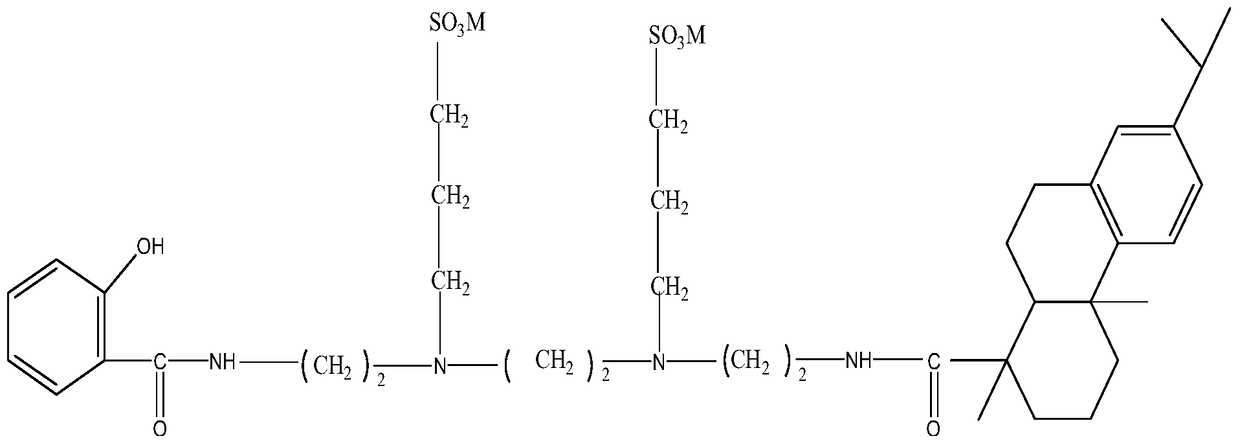

Method used

Image

Examples

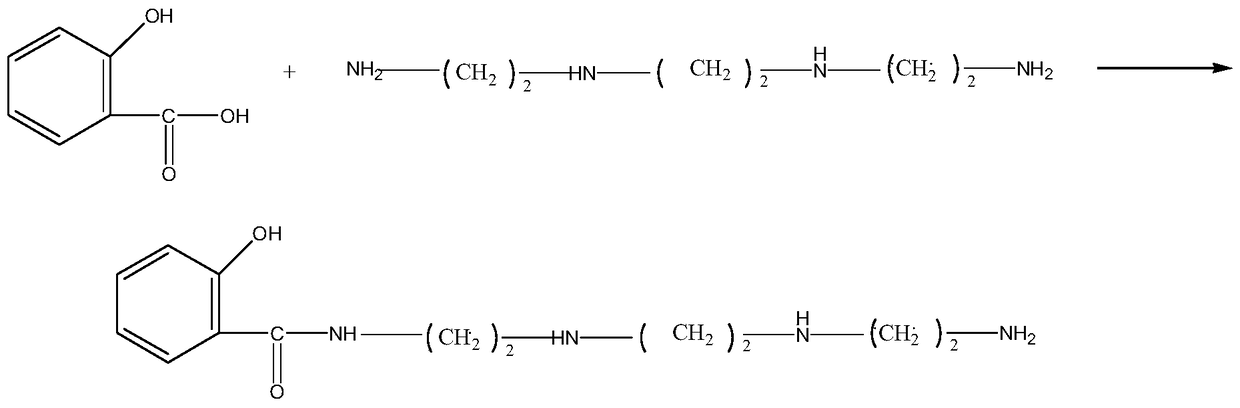

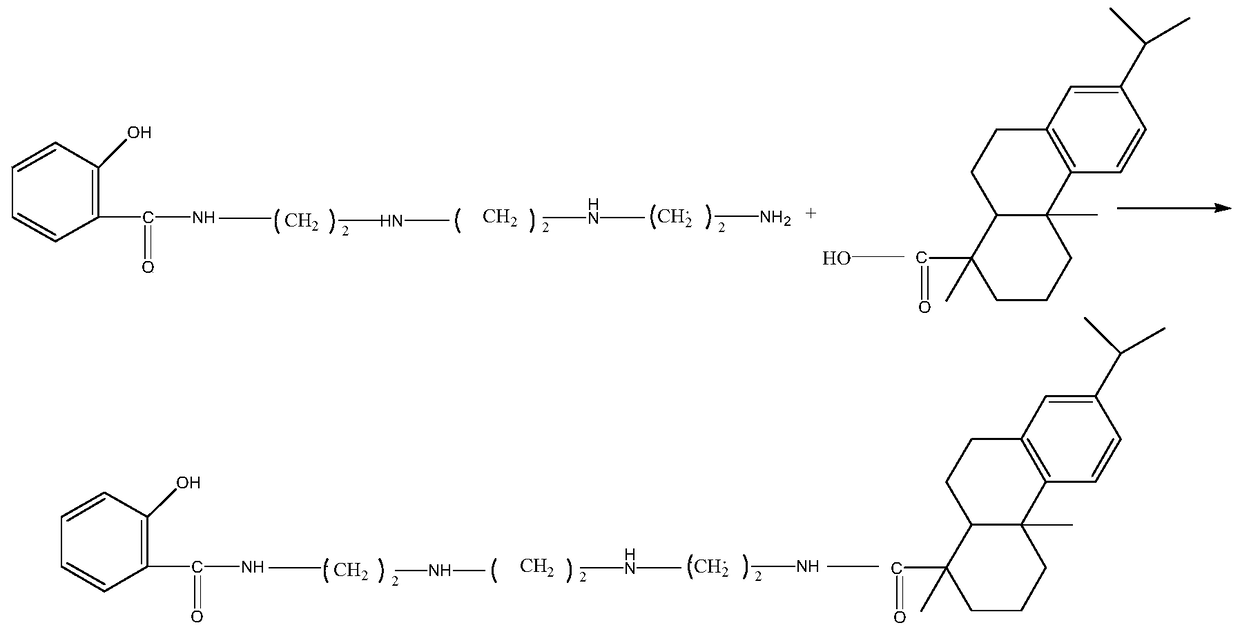

Embodiment 1

[0032] Add 20.7 grams of salicylic acid and catalyst potassium hydroxide (adding by salicylic acid quality 1.5%) in the 250ml four-neck flask that condenser tube, thermometer and stirrer are housed, open stirring, be warming up to 90 ℃ under nitrogen protection, Slowly add 24.1 grams of triethylenetetramine dropwise to the reactor, and the dropwise addition is completed within 1 hour, then react at a constant temperature of 150-160°C for 6 hours, and cool to 25-30°C to obtain an intermediate monoamide, which is in the reactor Then add 45 grams of dehydroabietic acid, start stirring, raise the temperature to 90°C under the protection of nitrogen, then react at a constant temperature of 150-160°C for 6 hours, cool to 25-30°C, use 150# solvent oil and butanone mixed solvent (Volume ratio 1:1) recrystallize 3 times, remove by-products, dry in a vacuum oven at 60°C to constant weight, and obtain a white powder that is an intermediate asymmetric bisamide with a purity of more than 95...

Embodiment 2

[0035]Add 20.7 grams of salicylic acid and catalyst potassium hydroxide (adding by salicylic acid quality 1.5%) in the 250ml four-neck flask that condenser tube, thermometer and stirrer are housed, open stirring, be warming up to 90 ℃ under nitrogen protection, Slowly add 24.1 grams of triethylenetetramine dropwise to the reactor, and the dropwise addition is completed within 1 hour, then react at a constant temperature of 150-160°C for 6 hours, and cool to 25-30°C to obtain an intermediate monoamide, which is in the reactor Then add 45 grams of dehydroabietic acid, start stirring, raise the temperature to 90°C under the protection of nitrogen, then react at a constant temperature of 150-160°C for 6 hours, cool to 25-30°C, use 150# solvent oil and butanone mixed solvent (Volume ratio 1:1) recrystallize 3 times, remove by-products, dry in a vacuum oven at 60°C to constant weight, and obtain a white powder that is an intermediate asymmetric bisamide with a purity of more than 95%...

Embodiment 3

[0038] Add 20.7 grams of salicylic acid and catalyst potassium hydroxide (adding by salicylic acid quality 1.5%) in the 250ml four-neck flask that condenser tube, thermometer and stirrer are housed, open stirring, be warming up to 90 ℃ under nitrogen protection, Slowly add 24.1 grams of triethylenetetramine dropwise to the reactor, and the dropwise addition is completed within 1 hour, then react at a constant temperature of 150-160°C for 6 hours, and cool to 25-30°C to obtain an intermediate monoamide, which is in the reactor Then add 45 grams of dehydroabietic acid, start stirring, raise the temperature to 90°C under the protection of nitrogen, then react at a constant temperature of 150-160°C for 6 hours, cool to 25-30°C, use 150# solvent oil and butanone mixed solvent (Volume ratio 1:1) recrystallize 3 times, remove by-products, dry in a vacuum oven at 60°C to constant weight, and obtain a white powder that is an intermediate asymmetric bisamide with a purity of more than 95...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com