Screening and storage system of electronically controlled rice precision hole direct seeding machine

A technology for direct seeding and rice in holes, applied in the field of screening and storage systems, can solve the problems of uneven grain size and insurmountability in holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing, the present invention is made further.

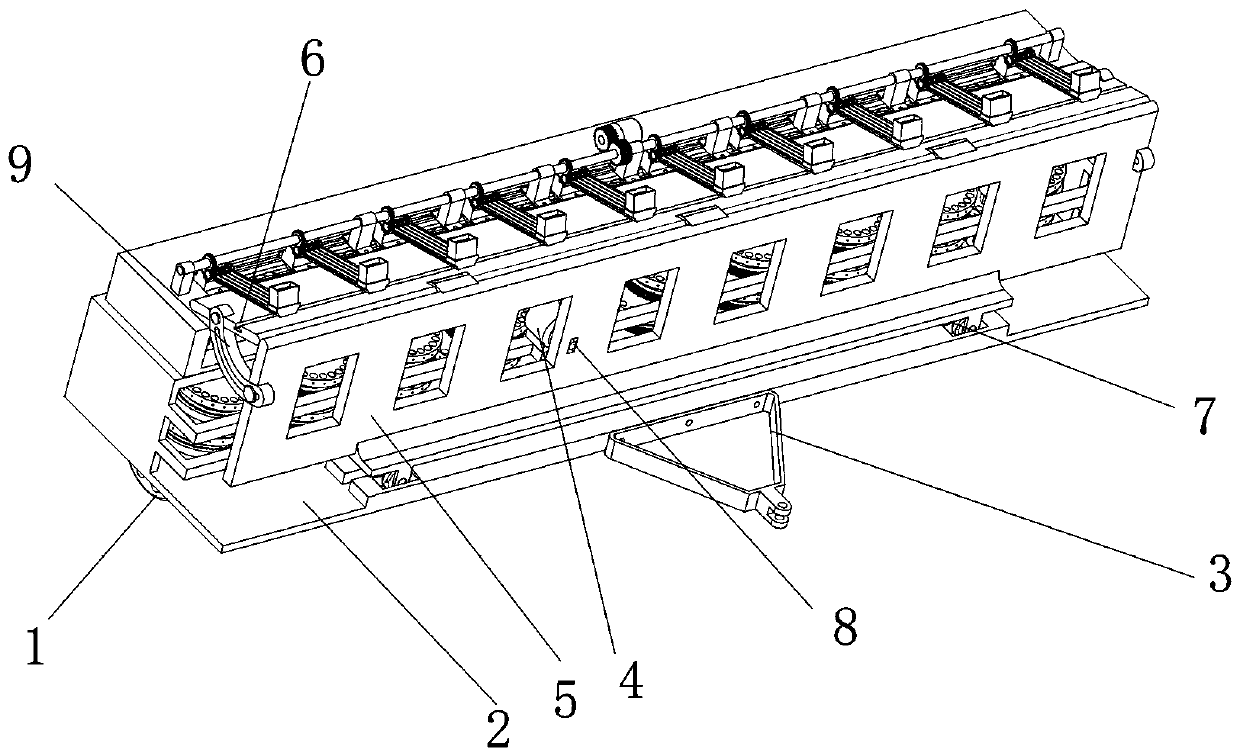

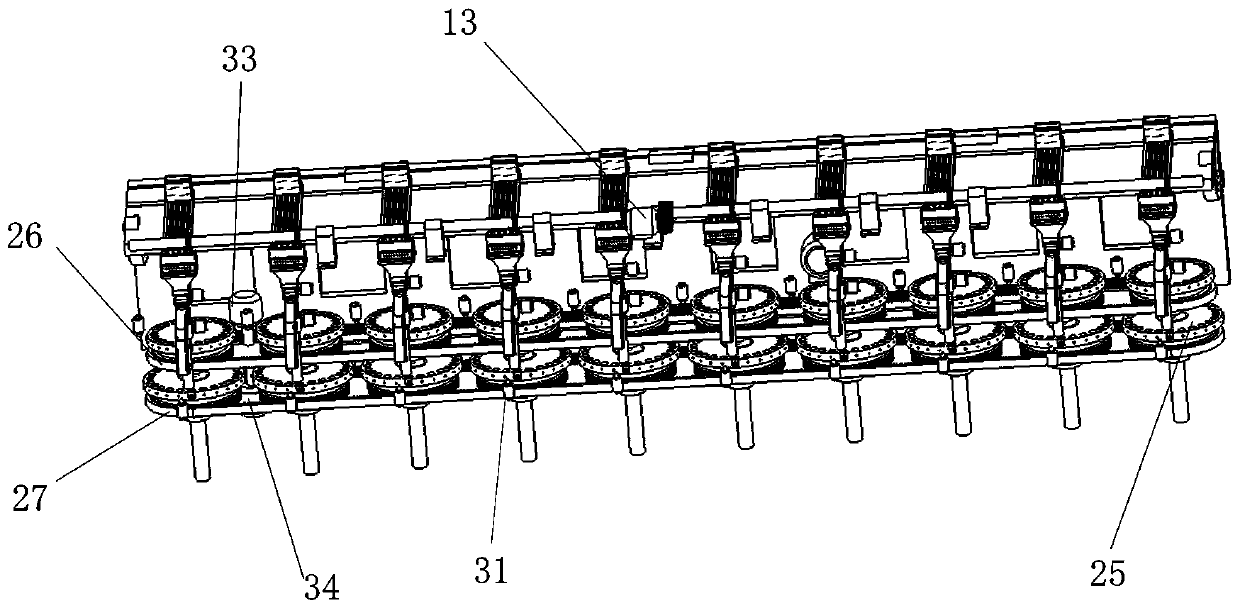

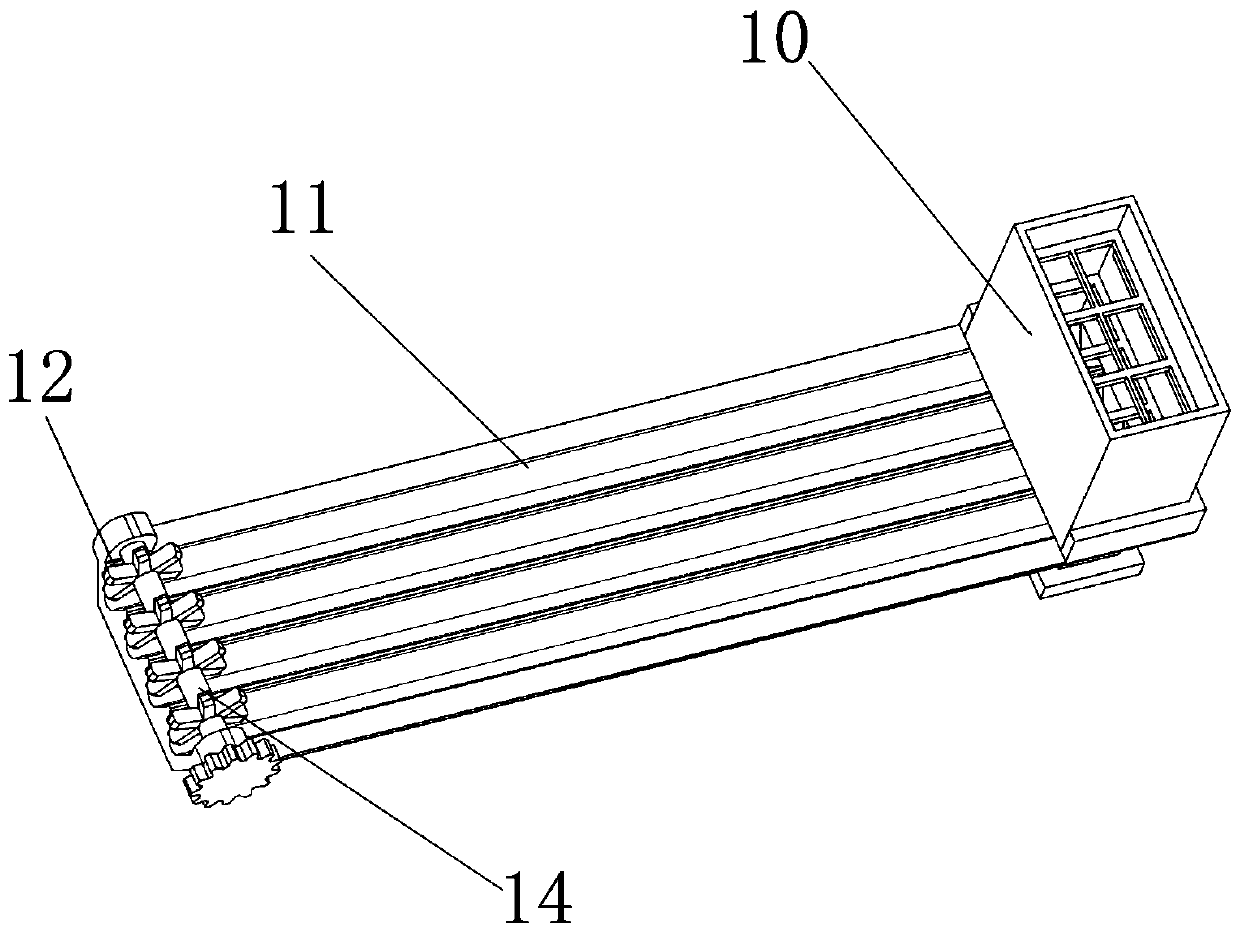

[0015] Such as Figure 1-7 As shown, the electronically controlled rice precision hole direct seeding machine of the present invention includes a chassis assembly, a vibration assembly, a rice grain setting assembly, an installation frame assembly, a screening and storage system, and a storage hole and sowing system.

[0016] Described chassis assembly comprises wheel 1, chassis 2 and traction frame 3, is the foundation that all components are installed, and wheel 1 is arranged on the bottom of chassis assembly, and traction frame 3 is arranged on the front of chassis assembly, is pulled by tractor.

[0017] The chassis assembly is provided with a vibration assembly, the vibration assembly includes a vibration motor 4, a vibration table substrate 5, a vibration table adjustment plate 6 and a vibration table roller 7, and the vibration table substrate 5 is arranged on the vibration t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com