Indicator light installation structure and detection cabinet thereof

A technology of installation structure and indicator light, applied in the direction of electrical equipment shell/cabinet/drawer, printed circuit connected with non-printed electrical components, electrical components, etc., can solve electromagnetic leakage, electromagnetic shielding is ineffective, thickness is difficult to control, etc problems, to achieve the effect of simplifying product structure, simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

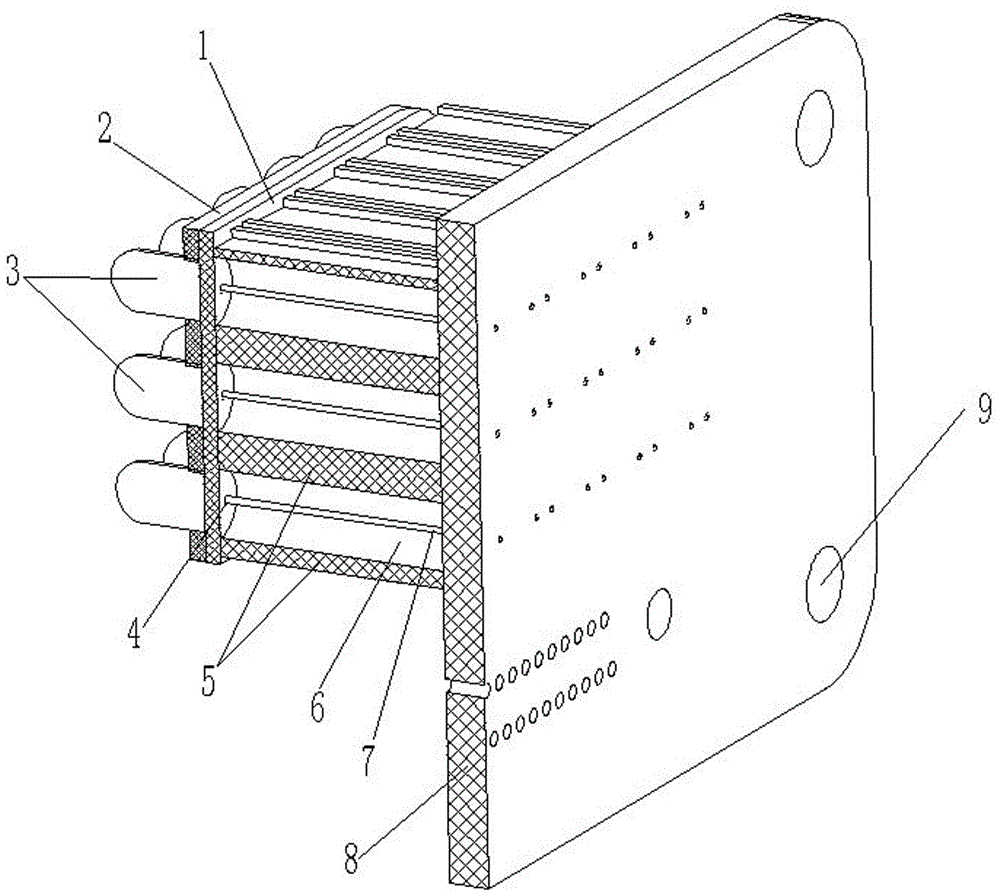

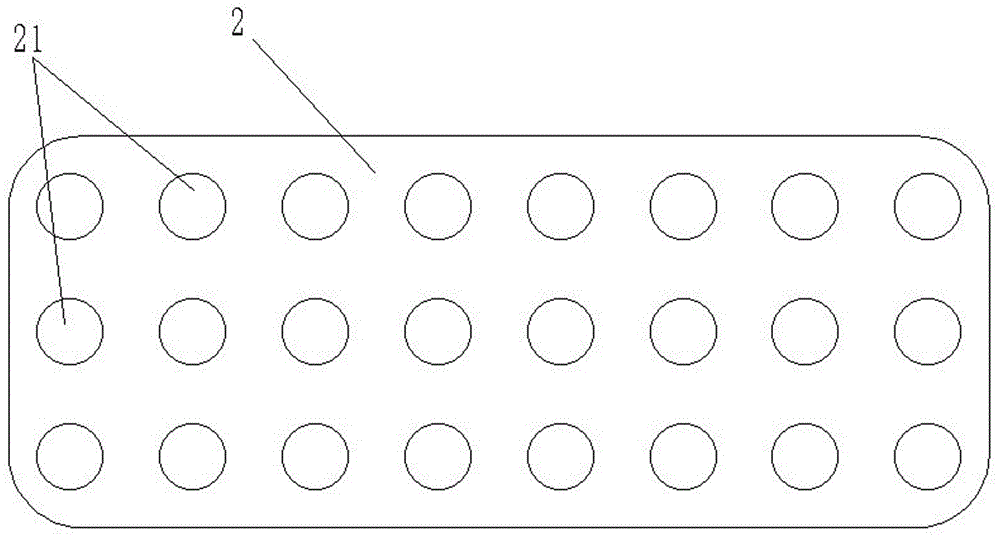

[0026] Examples of detection cabinets are Figure 1~4 As shown: it includes a panel 10, a cabinet body 3 and an indicator light installation structure. The indicator light installation structure includes a plurality of indicator lights 3 arranged on the panel and a printed board 8 arranged in the cabinet. The printed board 8 is located in the indicator light On the rear side, the indicator light 3 is a diode, and the indicator light is connected to the printed board 8 through the indicator pin 7 extending along the front and rear directions. The installation structure of the indicator light also includes a first gasket 2 made of a conductive rubber pad, the first gasket is provided with an indicator light installation hole 21 corresponding to each indicator light, and the aperture of each indicator light installation hole 21 is smaller than that of the corresponding indicator light. The outer diameter of each indicator light is installed in the corresponding indicator light in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com