Motor

A rotor and stator technology, applied in the field of motors, can solve the problems of Hall chip installation and positioning troubles, increase the difficulty of iron core manufacturing, Hall chips cannot be installed compactly, etc., and achieve a more compact and reasonable motor structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

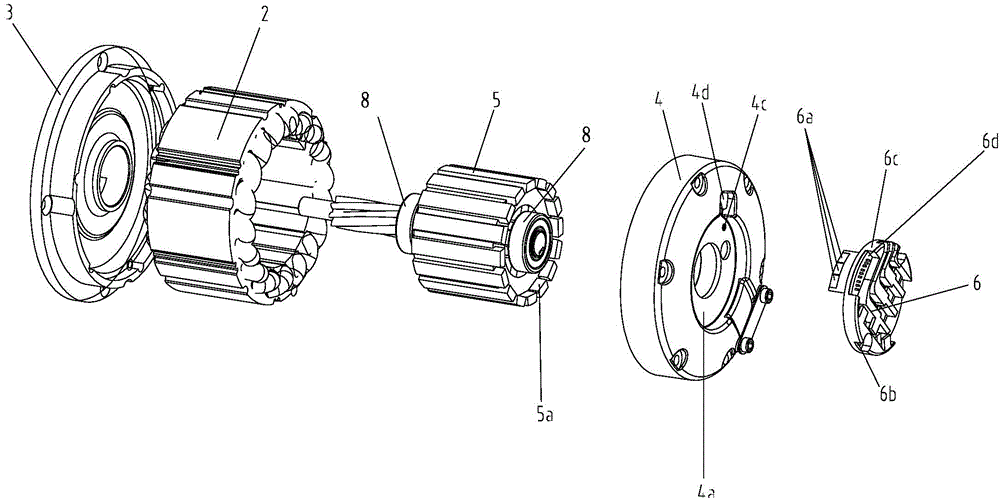

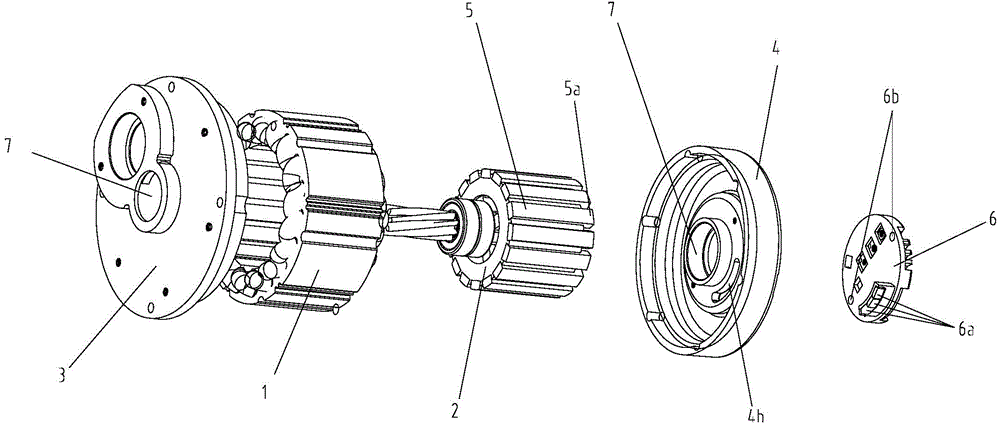

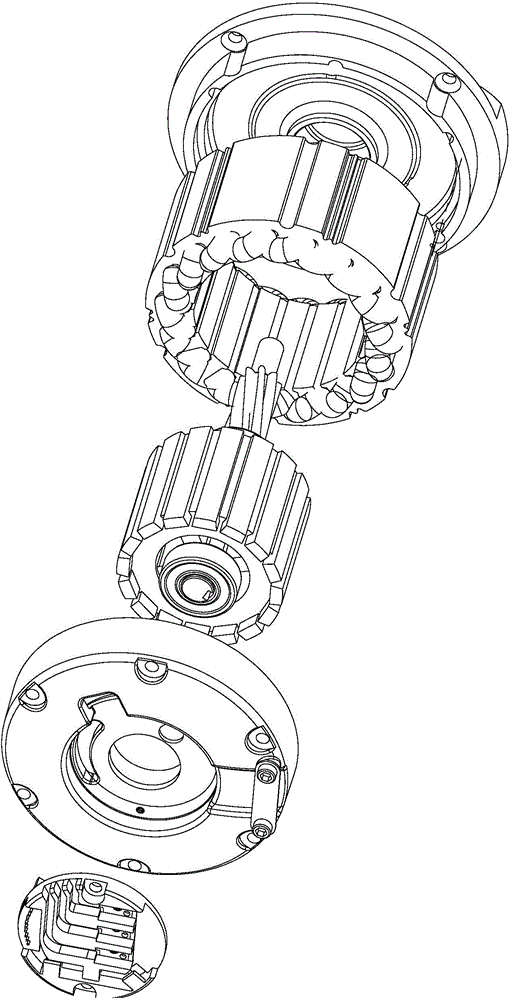

[0020] Figure 1 ~ Figure 3 A specific embodiment of the motor of the present invention is shown. The motor is an inner-rotor-outer-stator motor, which includes a rotor 1, a stator 2 sleeved outside the rotor, and is arranged on the front side of the stator and is opposite to the stator. A fixed front cover 3, and a rear cover 4 which is arranged on the rear side of the stator and is relatively fixed to the stator, and the periphery of the rotor 1 is fixed with a plurality of rare earth magnets 5 which are evenly spaced in a circular shape. The rare earth magnets 5 are strip-shaped and arranged parallel to the axial direction of the rotor 1 . The number of rare earth magnets 5 described in this example is 16 in total.

[0021] The key improvement of this embodiment is: in this example, the rear end of each rare earth magnet 5 has been lengthened so that the rear end of each rare earth magnet 5 extends backward by a certain length and protrudes beyond the rotor 1. The rear en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com