Parallel structure and preparation of flexible TFT drive bottom-emitting OLED/PLED (organic/polymer light-emitting diode)

A bottom emission, flexible technology, applied in electrical components, electrical solid devices, circuits, etc., can solve problems such as high defect rate and complex process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

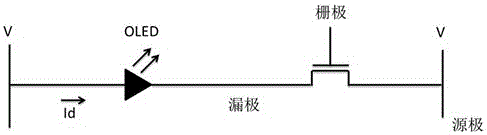

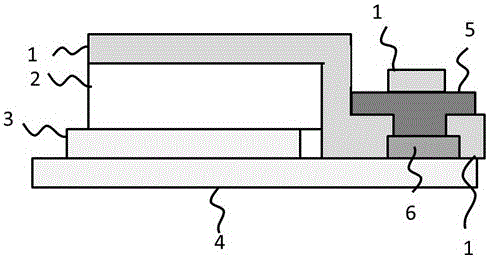

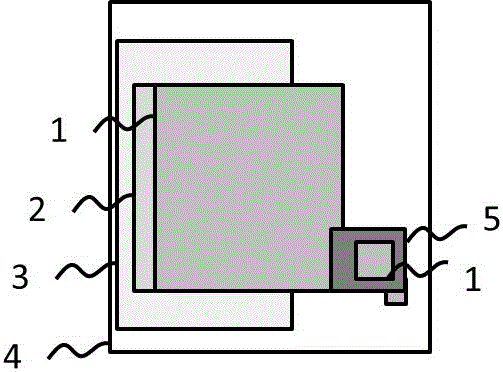

[0017] Such as figure 1 As shown, the OLED / PLED pixel unit driving circuit of the present invention includes a flexible substrate, an OLED / PLED device, a flexible transistor, a transparent electrode, and various conductive metal layers. The specific production steps are as follows:

[0018] The first step is to deposit the required TCO and ZTO electrodes on the flexible substrate, or form the required electrode circuit pattern by etching.

[0019] In the second step, the cut and etched ITO and ZTO flexible substrates are first cleaned with detergent to remove impurities and oil stains on the surface, and then undergo three steps of cleaning agent ultrasonic cleaning, ultrapure water ultrasonic cleaning, and ethanol ultrasonic cleaning After ultrasonic cleaning, dry in an oven.

[0020] In the third step, the ITO and ZTO flexible substrates dried in the above steps are subjected to ultraviolet ozone treatment for 15 minutes in the ultraviolet ozone treatment chamber.

[0021...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com