Hot air heat utilization system for indirect cooling tower

A cooling tower and indirect technology, applied in the field of indirect cooling tower warm air heat utilization system, can solve problems such as low energy level and achieve the effects of reducing steam extraction, improving operation safety, and improving operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in further detail below in conjunction with accompanying drawing:

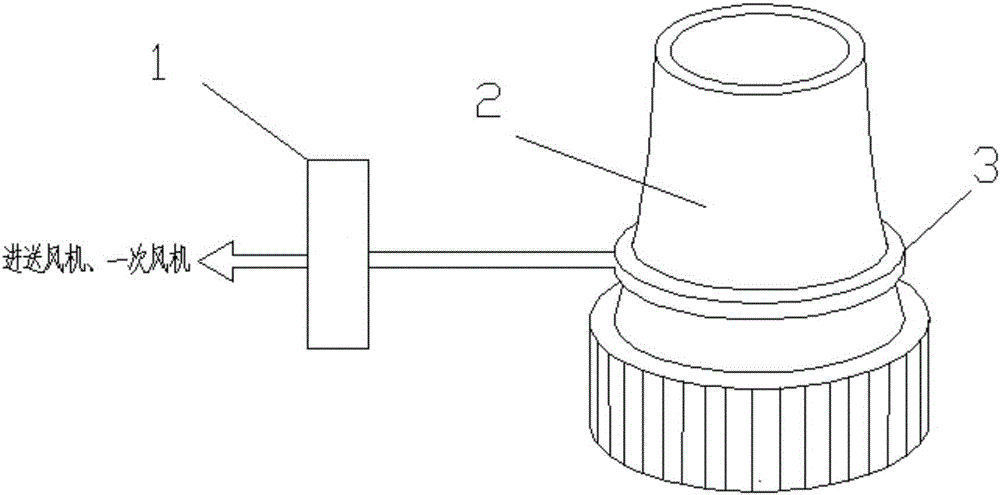

[0019] see figure 1 , the present invention includes an indirect cooling tower 2 and an air inlet header 1; 8 air outlets are arranged symmetrically at 8 to 15 m above the heat exchange area of the indirect cooling tower 2, and the air outlets are evenly distributed along the circumference, and the diameter of the air outlets is 6 ~7m, the angle between it and the horizontal square line is 70°~90°; the outer side of the air outlet is provided with an annular air intake box 3, and the annular air intake box 3 is sealed and connected with the outside of the indirect cooling tower 2, and the outer diameter of the annular air intake box 3 The width between the inner diameter and the inner diameter is 5-7m, and the height is 7-8m; the outlet of the annular air intake box 3 is connected to the air inlet header 1, and the warm air from the indirect cooling tower 2 passes th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com