engine air intake

A technology for air intake devices and engines, applied in the direction of engine components, machines/engines, charging systems, etc., can solve the problem of not being able to distribute air, not sufficiently reducing the ventilation resistance of the intake device, and not considering the reduction of the ventilation resistance of branch pipes Equalization of air intake distribution and other issues to achieve the effects of improving output performance, reducing bending, and reducing ventilation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

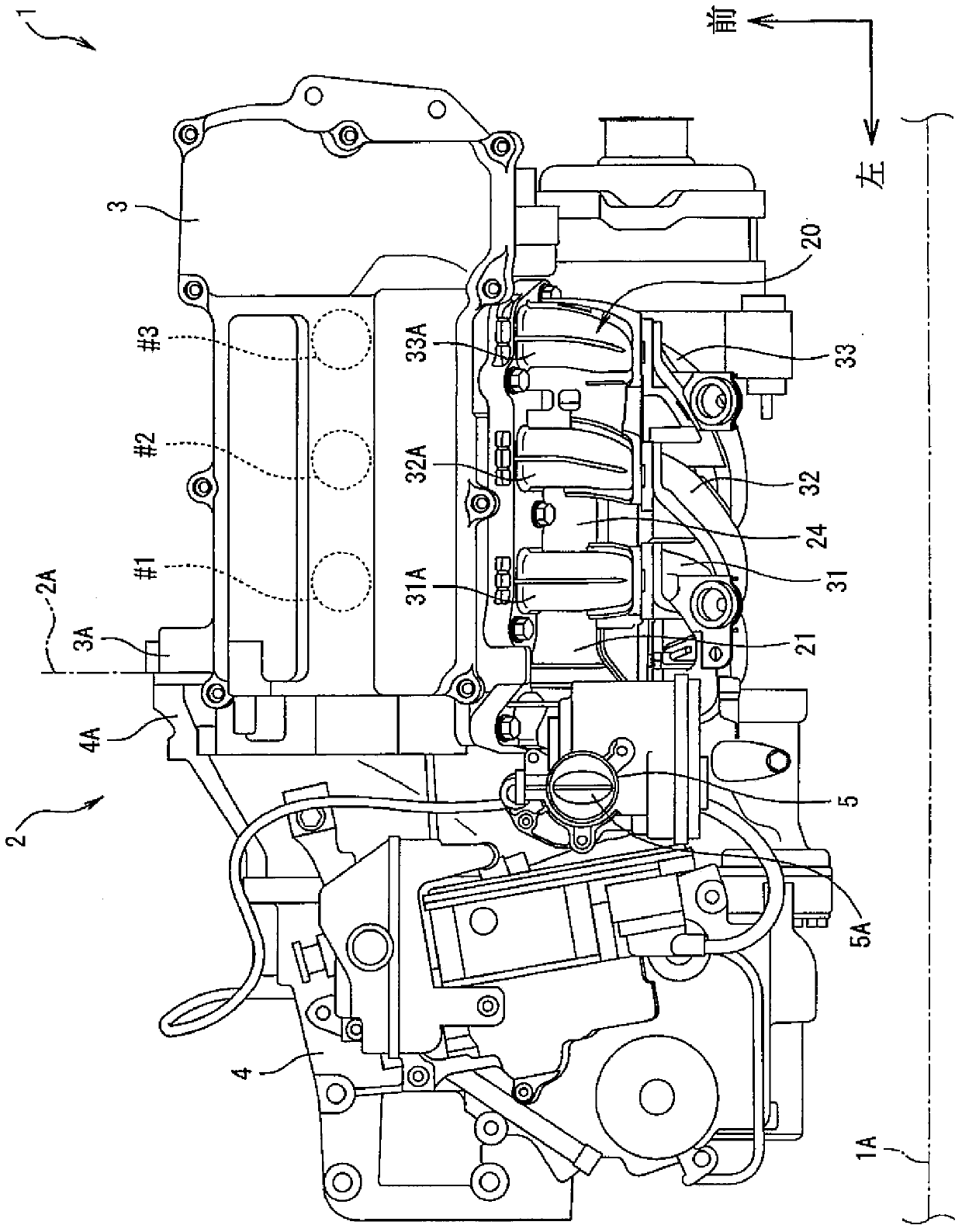

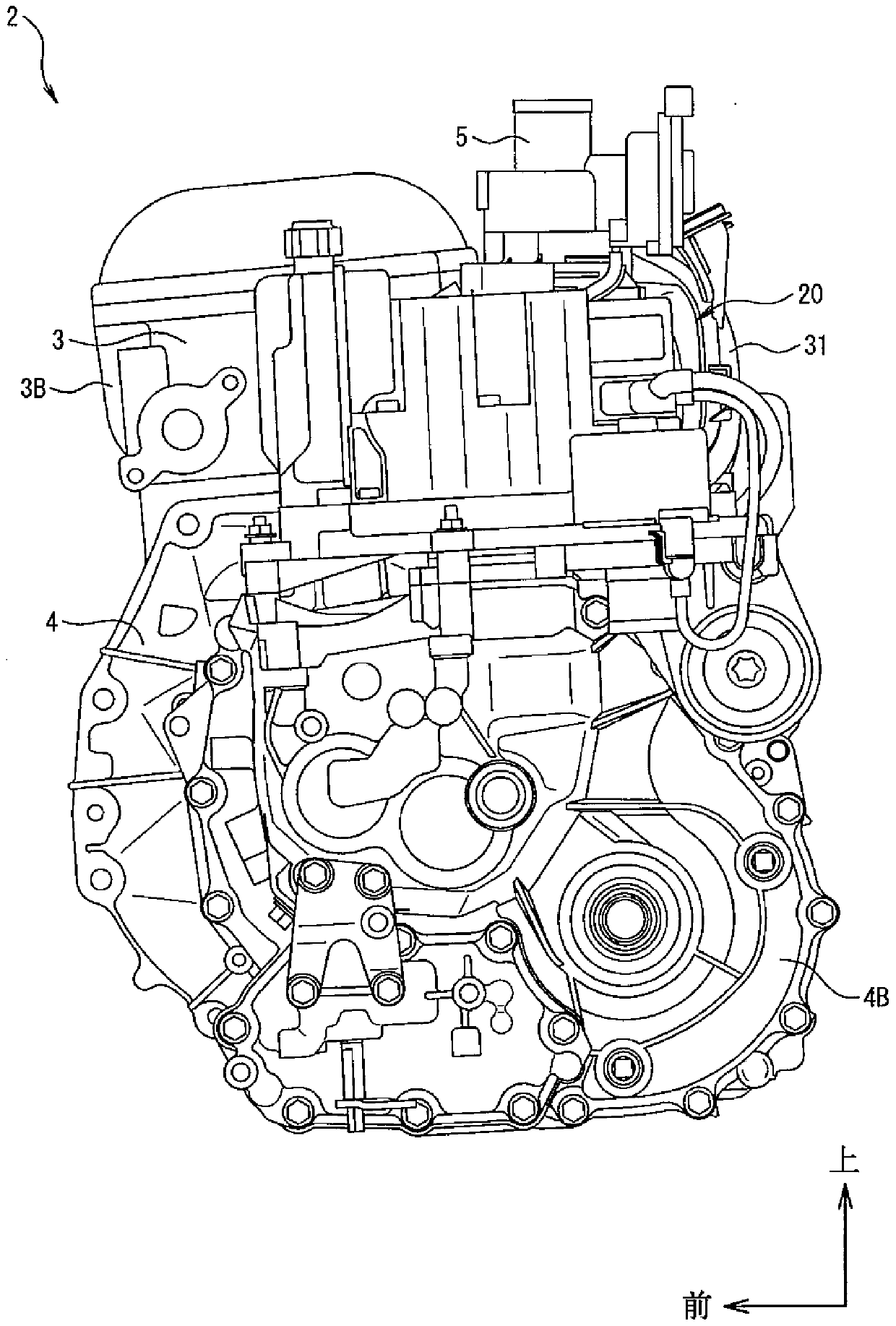

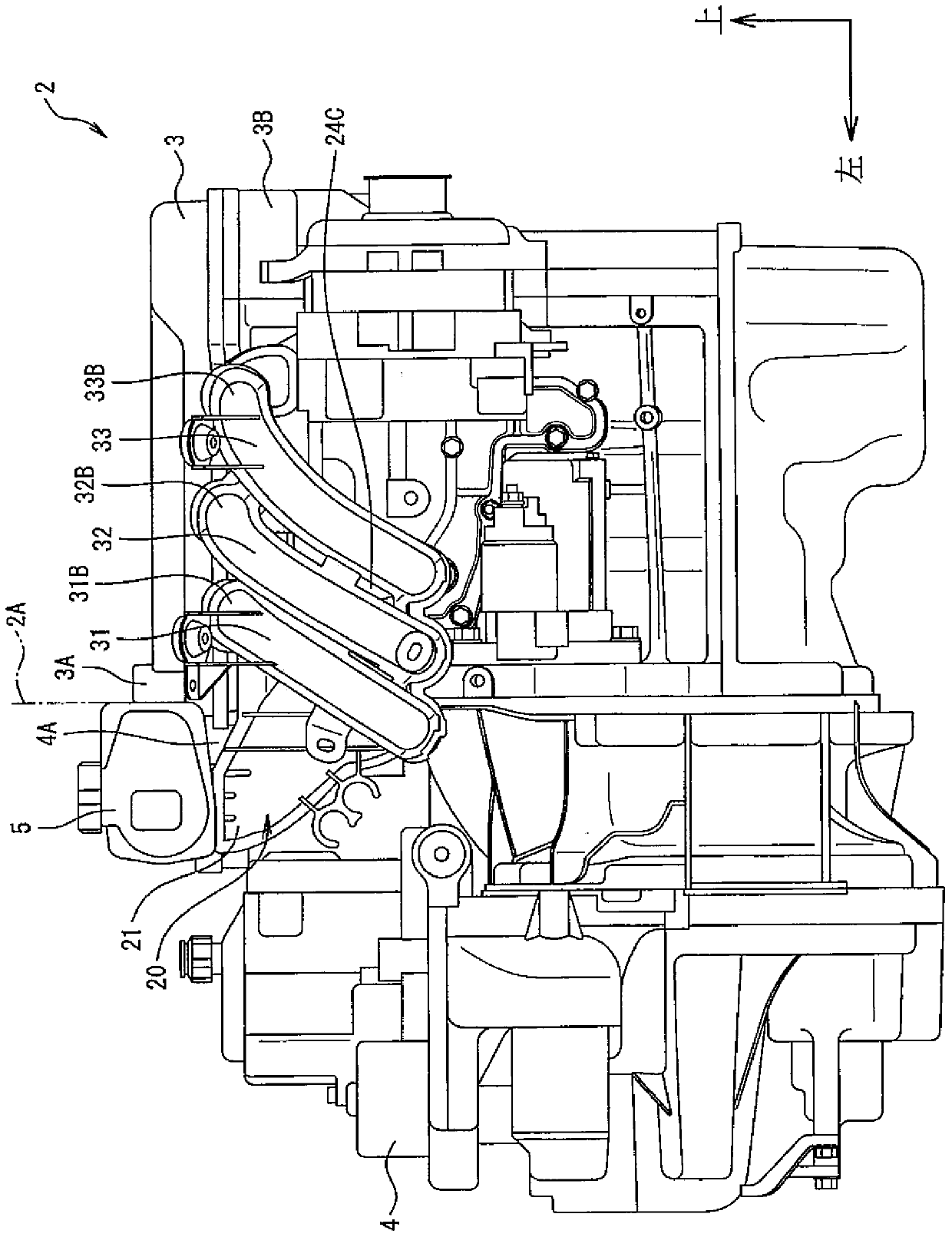

[0032] Embodiments of an air intake device for an engine according to the present invention will be described below using the drawings. Figure 1 to Figure 9 It is a figure which shows the air intake device of the engine which concerns on one Embodiment of this invention.

[0033] First, the configuration will be described. exist figure 1 In the vehicle 1, a power system 2 is installed on the vehicle 1, and the power system 2 is installed laterally in front of the instrument panel 1A of the vehicle 1. The instrument panel 1A is provided in front of an unillustrated driver's seat, and separates a space in which the powertrain 2 is arranged from the driver's seat.

[0034] In the present embodiment, the front-rear, left-right, and up-down directions are indicated by arrows in the figure so as to correspond to the front-rear direction, left-right direction, and up-down direction viewed by the driver sitting on the driver's seat of the vehicle 1 .

[0035] The power system 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com