Electrotinning additive and preparation method and use method thereof

An additive and electroplating tin technology, applied in the field of electroplating tin additive and its preparation, can solve the problem of high temperature and achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Carry out the proportioning and weight percentage of each component according to the following ratio: TritonCF-10 type nonionic surfactant 5%, LugalvanBNO12 type β-naphthol polyoxyethylene ether 10%, APG type alkyl glucoside 3%, LugalvanHS1000 type Thiodiglycol ethylate 3%, catechol 2%, and the rest is deionized water.

[0025] Among them, TritonCF-10 type nonionic surfactant is provided by Dow Chemical Company, LugalvanBNO12 type β-naphthol polyoxyethylene ether and LugalvanHS1000 type thiodiglycol ethyl compound are provided by BASF, and APG type alkyl glycoside is provided by Shanghai Provided by Fakai Chemical Co., Ltd.

[0026] The preparation process of this embodiment electroplating tin additive is:

[0027] ① Add 30% deionized water to the container;

[0028] ② When stirring, add non-ionic surfactant according to the ratio and stir evenly;

[0029] ③ While stirring, add β-naphthol polyoxyethylene ether at a constant speed according to the proportion, and cont...

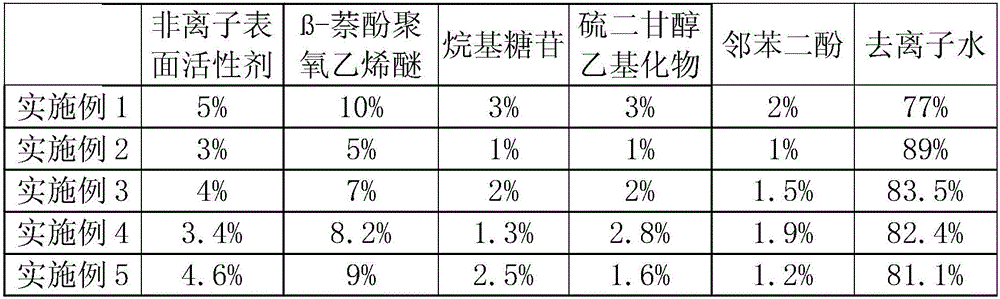

Embodiment 2-5

[0036] The method of Experimental Example 1 was repeated according to the content of each component specified in Table 1 below, to obtain electroplating tin additives with different formulations.

[0037] Table 1:

[0038]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap